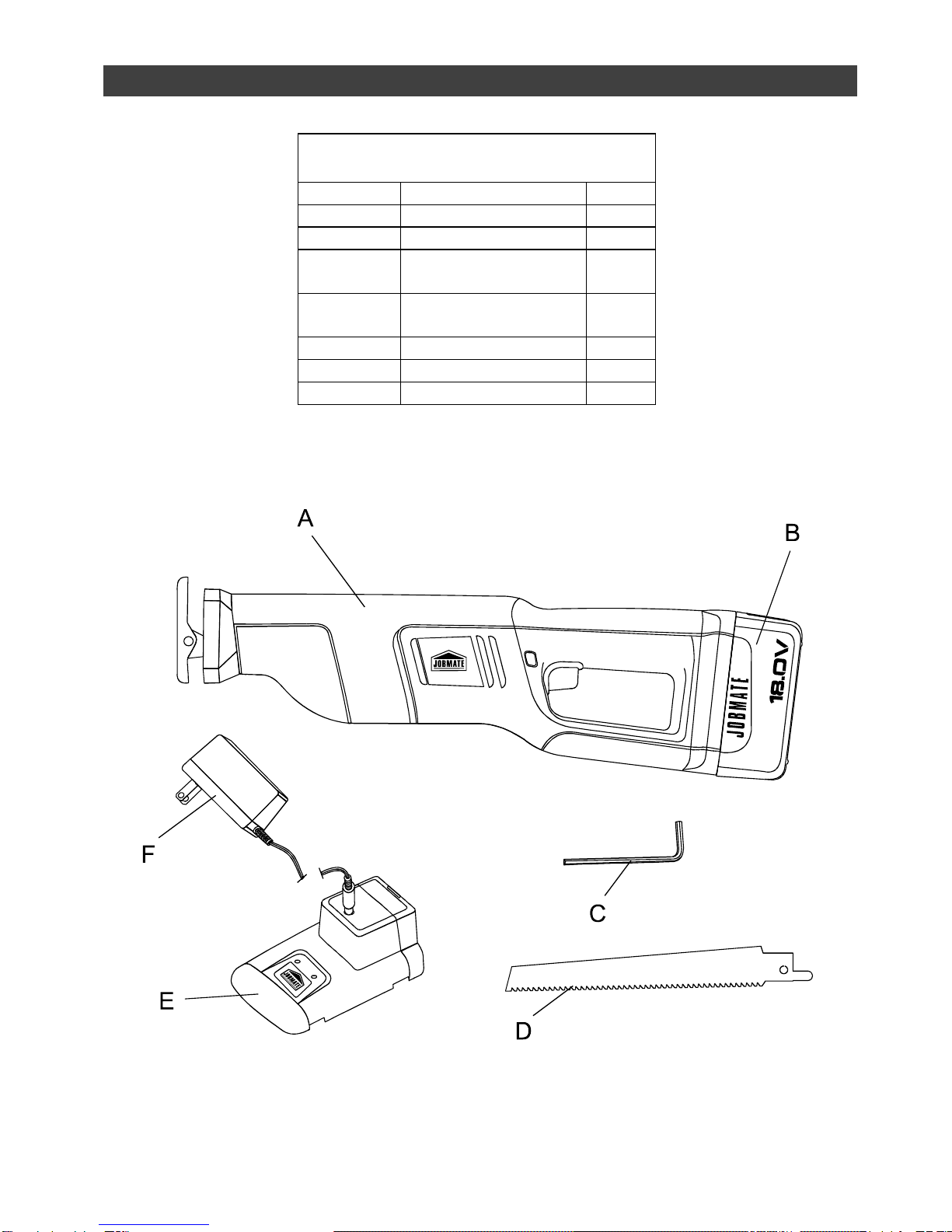

●DANGER: Always remove the

battery pack when changing blade.

●After changing a blade or making

adjustments, make sure the blade

clamp screw is securely tightened.

Loose blades and adjustment devices

could be violently thrown from the tool.

●Never use dull or damaged blades.

Sharp blades must be handled with

care. Damaged blades can snap

during use. Dull blades require more

force to cut the workpiece, possibly

causing the blade to break.

●Never touch the blade during or

immediately after use. After use the

blade is too hot to be touched.

●Do not store or carry battery pack in

a manner in which metal objects

could contact exposed metal end.

Do not place battery in aprons,

pockets, drawers, etc. with loose nails,

screws, keys etc. The battery could

short circuit causing a fire, personal

injury or damage to the battery.

●Never attempt to open the battery

pack for any reason. If the housing of

the battery breaks or cracks,

immediately discontinue use and do

not recharge.

●Do not charge the battery pack if it

is wet or shows any evidence of

corrosion.

●Do not incinerate the battery pack. It

can explode in a fire.

●Minor leakage from the battery pack

may occur under extreme usage,

charging or temperature conditions.

This does not indicate a failure. If,

however, the outer seal is broken and

this leakage gets on your skin, follow

these steps:

1. Wash immediately with soap and

water.

2. Neutralize with a mild acid such

as lemon juice or vinegar.

3. If liquid gets into your eyes, flush

immediately with clean water for a

minimum of 10 minutes and seek

medical attention.

NOTE: The battery fluid is a

20–35% solution of potassium

hydroxide.

●Do not use an extension cord. Plug

the charger cord directly into an

electrical outlet.

●Use the charger only in a standard

110–120 V/60 Hz electrical outlet.

●WARNING: The double-

insulated charger is equipped with a

polarized plug (one blade is wider than

the other). This plug will fit into a

polarized outlet only one way. If the

plug does not fit fully into the outlet,

reverse the plug. If it still does not fit,

contact a qualified electrician to install

a polarized outlet. Do not alter the plug

in any way. Double insulation

eliminates the need for the three-prong

grounded power cord and grounded

power supply system.

●Charge the battery pack only with

the charger supplied with the saw.