Safety

TX03679,00016D0-19-05MAY10-1/1

MB60223,000005E-19-09SEP08-1/1

TX03679,0001734-19-08JAN08-1/1

TX03679,00016D2-19-08JAN08-1/1

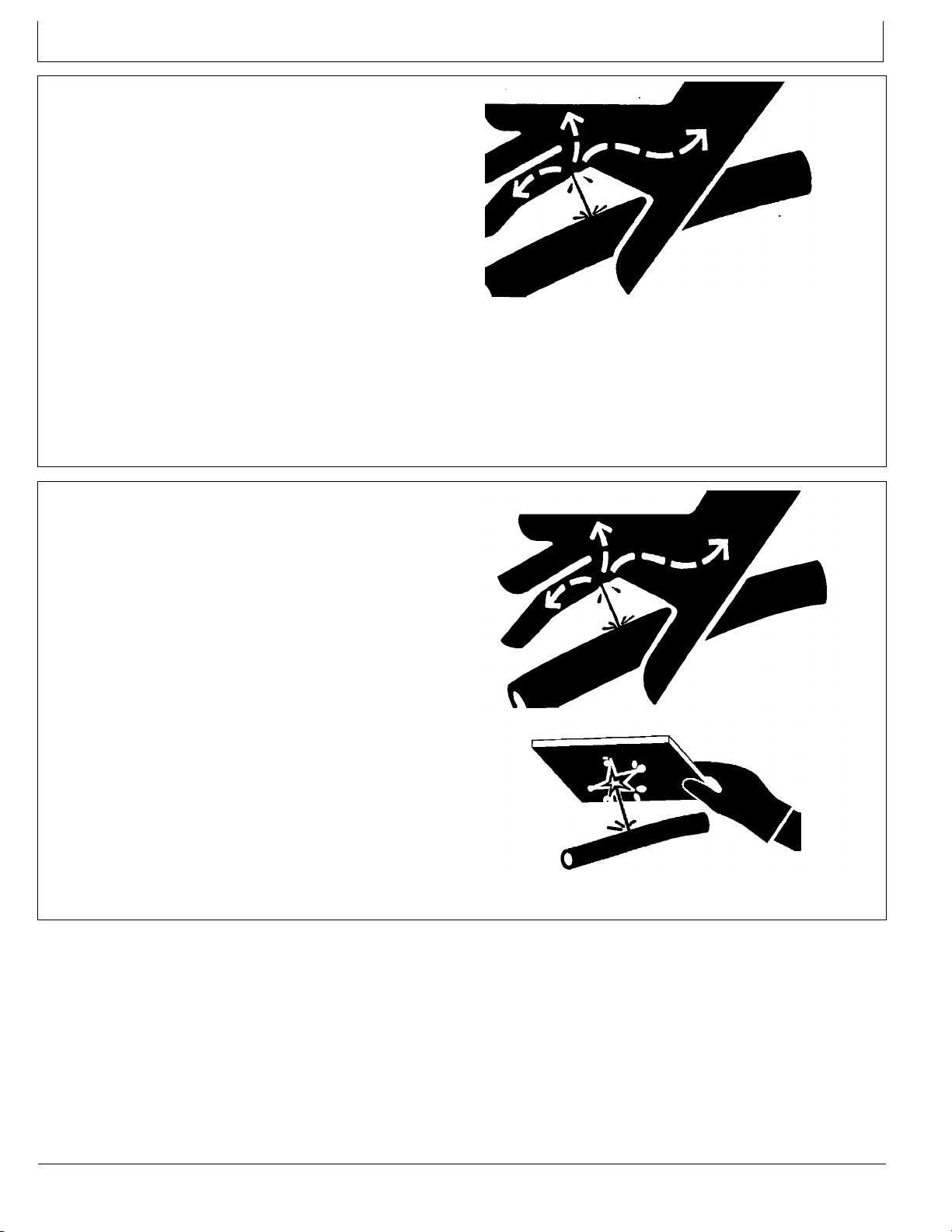

WearProtectiveEquipment

Guardagainstinjuryfromflyingpiecesofmetalordebris;

weargogglesorsafetyglasses.

Wearclosefittingclothingandsafetyequipment

appropriatetothejob.

Prolongedexposuretoloudnoisecancauseimpairment

orlossofhearing.Wearsuitablehearingprotectionsuch

asearmuffsorearplugstoprotectagainstobjectionable

oruncomfortableloudnoises.

TS206—UN—15APR13

AvoidUnauthorizedMachineModifications

JohnDeererecommendsusingonlygenuineJohnDeere

replacementpartstoensuremachineperformance.

NeversubstitutegenuineJohnDeerepartswithalternate

partsnotintendedfortheapplicationasthesecan

createhazardoussituationsorhazardousperformance.

Non-JohnDeereParts,oranydamageorfailuresresulting

fromtheirusearenotcoveredbyanyJohnDeerewarranty.

Modificationsofthismachine,oradditionofunapproved

productsorattachments,mayaffectmachinestabilityor

reliability,andmaycreateahazardfortheoperatoror

othersnearthemachine.Theinstallerofanymodification

whichmayaffecttheelectroniccontrolsofthismachineis

responsibleforestablishingthatthemodificationdoesnot

adverselyaffectthemachineoritsperformance.

Alwayscontactyoursupervisorbeforemakingmachine

modificationsthatchangetheintendeduse,weightor

balanceofthemachine,orthataltermachinecontrols,

performanceorreliability.

InspectMachine

Inspectmachinecarefullyeachdaybywalkingaroundit

beforestarting.

Keepallguardsandshieldsingoodconditionandproperly

installed.Fixdamageandreplacewornorbrokenparts

immediately.Payspecialattentiontohydraulichosesand

electricalwiring.

T6607AQ—UN—15APR13

StayClearofMovingParts

Entanglementsinmovingpartscancauseseriousinjury.

Stopenginebeforeexamining,adjustingormaintaining

anypartofmachinewithmovingparts.

Keepguardsandshieldsinplace.Replaceanyguard

orshieldthathasbeenremovedforaccessassoonas

serviceorrepairiscomplete.

T133592—UN—15APR13

TM10779(03MAY19)9000-01-2850JRMCTCrawlerDozer

050319

PN=8