Johnson Controls

Unitary Products

5005 York Drive, Norman, OK 73069

Form 665507-UIM-A-0311

10009029 B2205176B 3.11

TROUBLESHOOTING GUIDE

SYMPTOM POSSIBLE REASON/TROUBLESHOOTING PROCEDURE

Red LED On

Blower & compressor not running.

Open Float Switch

• If float switch not installed, confirm jumper installed at FLOAT SWITCH terminals.

• If float switch installed, confirm switch is not open.

• Clear obstruction in drain pan/tubing.

Red LED On

Blower is on but compressor not running.

High System Pressure/High Discharge Line Temperature Due to Lack of Airflow or Excessive

Inlet Temperature

• Check dehumidifier air filter and wash or replace.

• Check for blocked ductwork and clear.

Dehumidifier blower is running but little

or no airflow.

Pressure Drop Across Dehumidifier is Higher than 0.8” w.c.

• Check dehumidifier air filter and wash or replace.

• Check for blocked ductwork and clear.

• Check if back flow damper is blocked or stuck and remove obstruction.

Blower is running but compressor is not. Coil Frosting

• Lack of or reduced airflow, check/clean filter.

• Inlet air conditions too low (below 60°F), turn down dryness setting.

Blower 3 Minute Minimum “ON” Time

• Wait 3 minutes. Compressor will not start until blower has run for 3 minutes.

Dehumidifier is not draining properly. Incorrect Drain Installation

• Check drain line for continuous downward slope.

• Verify there are no kinks, traps or debris in drain line.

• If drain trap installed, confirm trap is properly installed, clear and primed.

• Unit is not level, adjust feet.

The dehumidifier does not run. No Power to Unit – Green LED Off (15 amp circuit required).

• Check that the power switch on the dehumidifier is ON.

• Check if circuit breaker has tripped.

Dehumidistat is OFF

• Turn on dehumidistat.

Dehumidifier is loud when operating. Fan Noise

• If inlet is not ducted to HVAC return, install approximately 2’ of 8” flex duct on inlet collar.

Vibration

• Install vibration isolators under dehumidifier feet.

Dehumidifier is producing hot air. This is normal operation.

Technical Support is available Monday through Friday, 8:00 a.m. to 5:00 p.m. CST, at (877) 874-7378. Use the troubleshooting guide to help

find and correct system faults. Contact Technical Support before replacing the unit or components or for additional troubleshooting.

SEQUENCE OF OPERATION

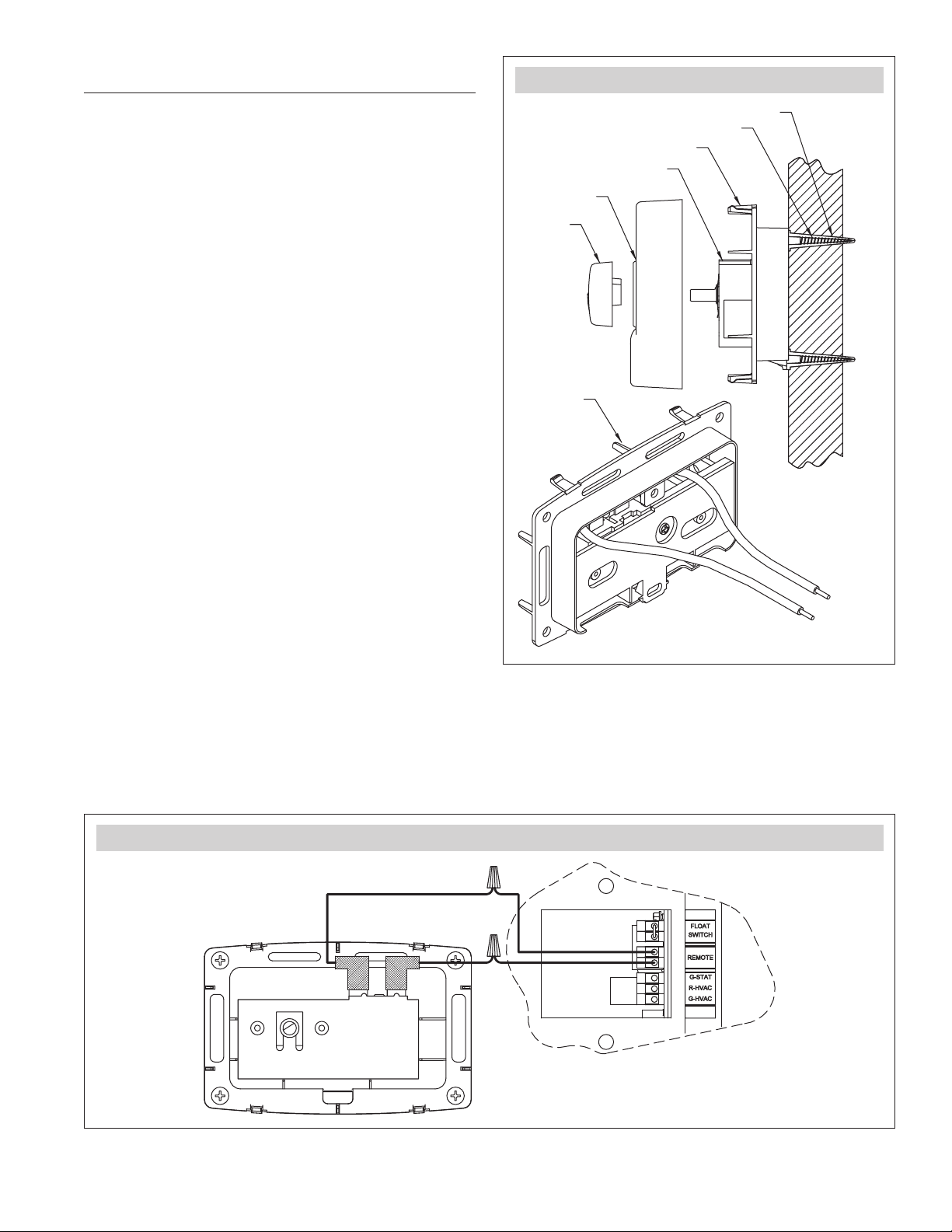

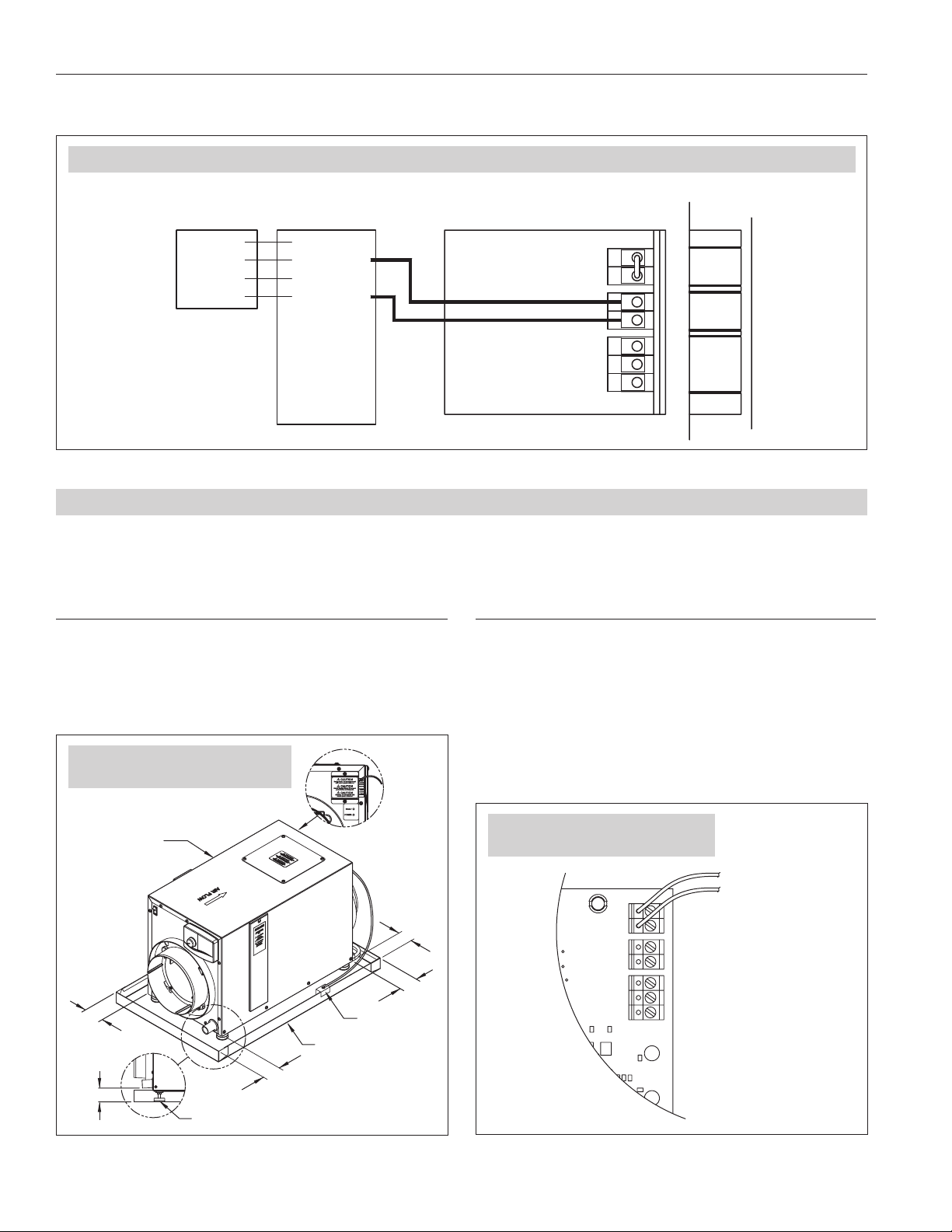

The dehumidistat continually measures the humidity of the air in which it is located and controls to the dryness level set on the dial. When

the humidity level rises above the dial setting on the dehumidistat, the dehumidifier blower will turn on and the DEH Amber LED on the power

board (not visible unless dehumidifier cover is removed, see wiring schematic) will illuminate. The HVAC system blower, along with the HVAC

Amber LED (not visible unless dehumidifier cover is removed, see wiring schematic) will also turn on if the dehumidifier is wired to the HVAC

system. After three minutes of blower operation, the dehumidifier compressor will turn on along with the COMPR Amber LED (not visible unless

dehumidifier cover is removed, see wiring schematic). When the humidity level drops below the dial setting on the dehumidistat, both the

compressor and dehumidifier blower will turn off. If wired to the HVAC system, the HVAC blower will also turn off unless the system thermostat

keeps it running. To prevent short-cycling, the compressor will turn on 3 minutes after the blower.

The dehumidifier is equipped with an automatic defrost feature. When the evaporator coil temperature drops below the cut-out point of the frost

sensor, the dehumidifier begins the defrost cycle and the dehumidistat will turn off the compressor and the blower will continue to run. The

compressor will remain off until the evaporator coil temperature rises above the cut-in point of the frost sensor.