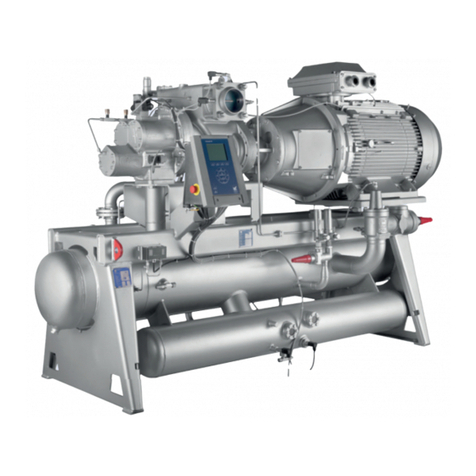

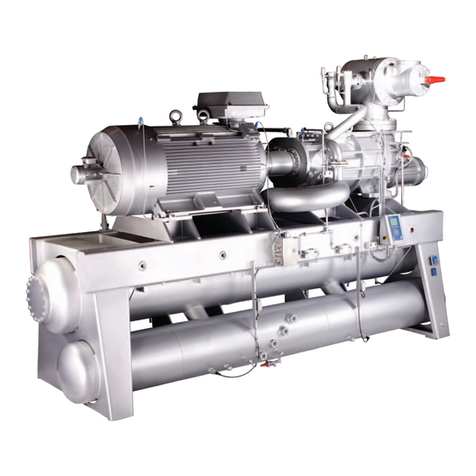

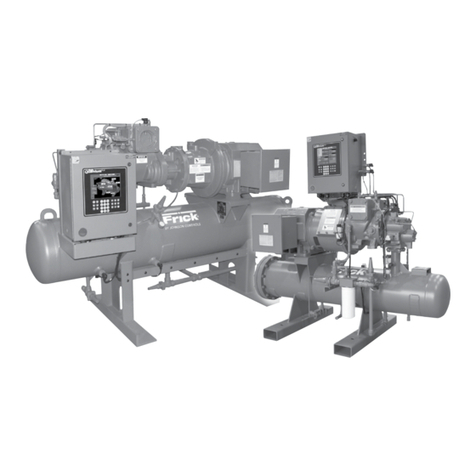

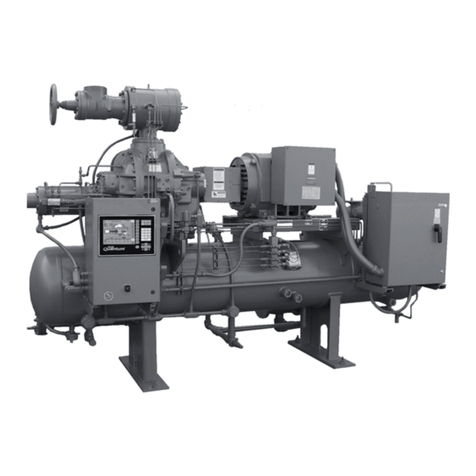

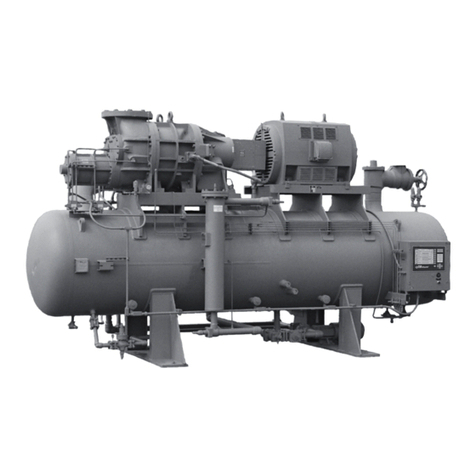

RXB PLUS ROTARY SCREW COMPRESSOR UNITS

INSTALLATION - OPERATION - MAINTENANCE

070.101-IOM (JAN 13)

Page 2

GENERAL INFORMATION

Preface .............................................................................. 3

Design Limitations ............................................................. 3

Job Inspection ................................................................... 3

Transit Damage Claims ..................................................... 3

Compressor/Unit Identification .......................................... 3

INSTALLATION

Foundation ......................................................................... 5

Handling and Moving ......................................................... 5

Skid Removal .................................................................... 6

Motor Mounting .................................................................. 6

Compressor/Motor Coupling Installation ........................... 6

Coupling Alignment Procedure .......................................... 7

Hot Alignment of Compressor/Motor ................................. 9

Checking Motor/Compressor Rotation .............................. 9

Holding Charge and Storage ............................................. 9

Compressor Oil .................................................................. 9

Oil Charge ......................................................................... 9

Oil Heater .......................................................................... 9

Liquid Injection Oil Cooling .............................................. 10

Dual Dip Tube Method ..................................................... 10

Level Control Method ....................................................... 10

Water-Cooled Oil Cooling ................................................ 10

Thermosyphon Oil Cooling .............................................. 11

Economizer - High Stage ................................................. 12

Electrical .......................................................................... 13

Motor Starter Package ..................................................... 14

Current Transformers (CT) Ratios ................................... 14

Minimum Burden Ratings ................................................ 14

Battery Backup ................................................................ 14

OPERATION

General Information ......................................................... 15

Microprocessor Control Panel ......................................... 15

Keys and Key Functions .................................................. 16

To Change The Adjustable Setpoints .............................. 18

How To Determine Adjustable Setpoints ......................... 18

Temperature-Pressure Control Program.......................... 22

Lead-Lag (Option) ........................................................... 24

Communications Troubleshooting .................................... 24

How The Microprocessor Works - Summary ................... 25

Multiple Compressor Sequencing .................................... 26

Microprocessor Telecommunications ............................... 27

Communications Protocol Specifications ........................ 27

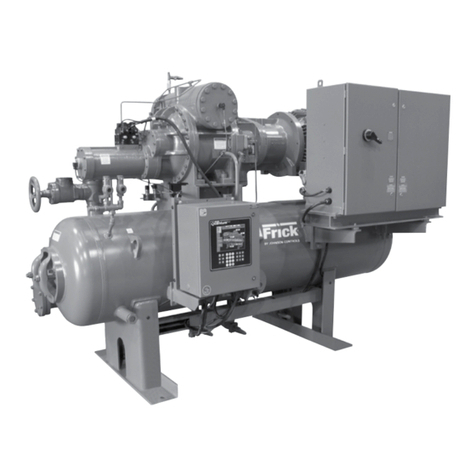

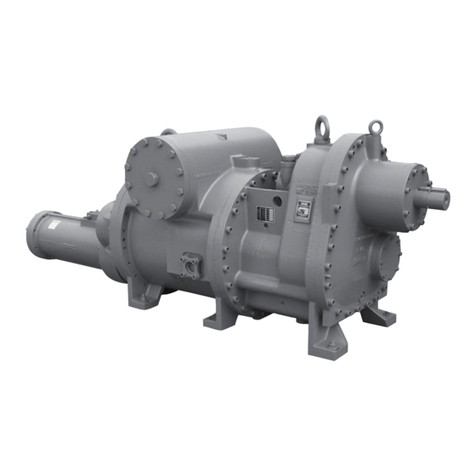

RXB Compressor ............................................................. 30

Compressor Lubrication System ..................................... 30

Full-Lube Oil System ....................................................... 30

Compressor Oil Separation System ................................ 30

Compressor Hydraulic System ....................................... 31

Compressor Oil Cooling Systems .................................... 32

Single-Port Liquid Injection .............................................. 32

Dual-Port Liquid Injection ................................................ 33

Liquid Injection Adjustment Procedure ............................ 33

TABLE OF CONTENTS

Prestart Checklist ............................................................ 34

Initial Start-up Procedure ................................................. 35

Normal Start-up Procedure ............................................. 35

Restarting Unit After Power Failure ................................. 35

MAINTENANCE

Normal Maintenance Operations ..................................... 36

Compressor Shutdown and Start-up ............................... 36

General Instructions For Replacing

Compressor Unit Components ..................................... 36

Suction Check Valve Bypass Valve .................................. 36

Oil Filter, Single ............................................................... 36

Oil Filter, Dual .................................................................. 37

Strainer, Oil Return .......................................................... 37

Strainer, Oil Pump (Optional) ........................................... 37

Strainer, Liquid Injection .................................................. 37

Coalescer Filter Element ................................................. 38

Changing Oil .................................................................... 38

Recommended Maintenance Program ............................ 38

Vibration Analysis ............................................................ 39

Oil Quality and Analysis ................................................... 39

Motor Bearings ................................................................ 39

Operating Log .................................................................. 39

Maintenance Schedule .................................................... 40

Troubleshooting Guide ..................................................... 41

Abnormal Operation Analysis and Correction ................. 41

Troubleshooting The Microprocessor ............................... 42

EPROM Memory I/C Chip Replacement ......................... 45

SBC Board Replacement ................................................ 45

Microprocessor Display Replacement ............................. 45

Output Fuse Replacement ............................................... 45

Pressure Transducers - Testing ....................................... 45

Pressure Transducer Conversion Data ............................ 45

Pressure Transducers - Replacement ............................. 46

Volumizer Potentiometer - Replace/Adjust ...................... 47

Temperature/Pressure Adjustment .................................. 47

Bare Compressor Mounting ............................................. 47

Troubleshooting The RXB PLUS:

Compressor ................................................................. 48

Oil Separator System ................................................... 48

Hydraulic System ......................................................... 48

Full-Time Pump Systems ............................................. 49

Liquid Injection Oil Cooling .......................................... 49

Thermal Expansion Valves .............................................. 50

Temperature Control Valve .............................................. 50

P and I Diagrams ............................................................. 51

Micro Component Placement Diagram ............................ 54

Wiring Diagrams .............................................................. 55

PROPER INSTALLATION OF ELECTRONIC

EQUIPMENT ................................................................ 60

OPERATING LOG ........................................................... 65