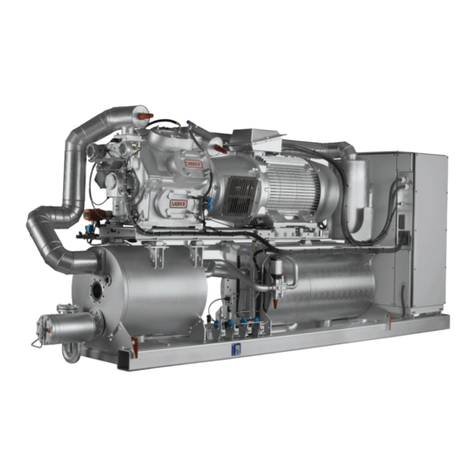

When the unit is delivered to the jobsite, check it thoroughly to

ensure all required items have been received and are free of any

shipping damage before signing the bill of lading. The following

parts should be inspected:

Sheaves and Belts Interior Surfaces

Bearings Exterior Surfaces

Bearing Supports Float Valve Assembly(s)

Fan Motor(s) Cold Water Basin Accessories

Fan Guards(s) Spray Water Pumps

Fan(s) and Fan Shaft(s) Water Distribution System

Coil Surface Louvers

Mating Surfaces Between Sections/Modules

Miscellaneous Items: All bolts, nuts, washers, and sealer tape

required to assemble sections or component parts are furnished

by Frick and shipped with the unit. A checklist inside the envelope

attached to the side of the unit marked “Contractor’s Installation

Instructions” indicates what miscellaneous parts are included

with the shipment and where they are packed.

Before rigging any unit, the weight of each section should be

verified from the unit certified drawing. Unit print weights include

the final assembled condenser with all accessories. Accessory

weights (found on the respective drawing) can be deducted

from the total weight.

must

Bolt holes, 7/8 in. diameter, are provided in the bottom flange of

the basin section for bolting the unit to the support beams. Refer

to the suggested support details on the certified drawing for loca-

tions of the mounting holes. Anchor bolts are supplied by others.

The support beams and unit must be level for proper operation.

Shims should not be used between the basin and support beams

to level the unit.

Adequate precautions appropriate for the installation and

location of these products should be taken to safeguard the

equipment and the premises from damage and the public from

possible injury.

When the fan speed of the unit is to be changed from the factory

set speed, including the use of a variable speed device, steps

must be taken to avoid operating at or near the fan’s “critical

speed” which could result in fan failure and possible injury or

damage. Consult with your local Frick Representative on any

such applications.

These products must be protected by mechanical and operational

methods against damage and/or reduced effectiveness due to

possible freeze-up. Please refer to the Common Operation

and Maintenance Manual on www.johnsoncontrols.com/frick

or contact your local Frick Representative for recommended

protection alternatives.

All evaporative cooling equipment must be located to ensure an

adequate supply of fresh air to the fans. When units are located

adjacent to walls or in enclosures, care must be taken to ensure

the warm, saturated, discharge air is not deflected and short-

circuited back to the air intakes.

Each unit must be located and positioned to prevent the introduc-

tion of discharge air into the ventilation systems of the building on

which the unit is located and of adjacent buildings. For detailed

recommendation on Frick equipment layout, see our website at

www.johnsoncontrols.com/frick or contact your local Repre-

sentative.

Please refer to the Limitation of Warranties (located in the

submittal package) applicable to and in effect at the time of the

sale/purchase of these products.

Refer to for the recommended vertical dimension “H”

from the lifting device to the spreader bar. In the event of ex-

tended lifts or where hazards exist, the lifting devices should

be used in conjunction with safety slings placed under the unit.