Johnson Controls Ducted Systems 5151094-UIM-H-0220

®

SINGLE PACKAGE

HEAT PUMP/ELECTRIC HEAT

MODELS: PHE4 SERIES

3 TO 5 TONS - 208/230 V - 3 PHASE

INSTALLATION MANUAL

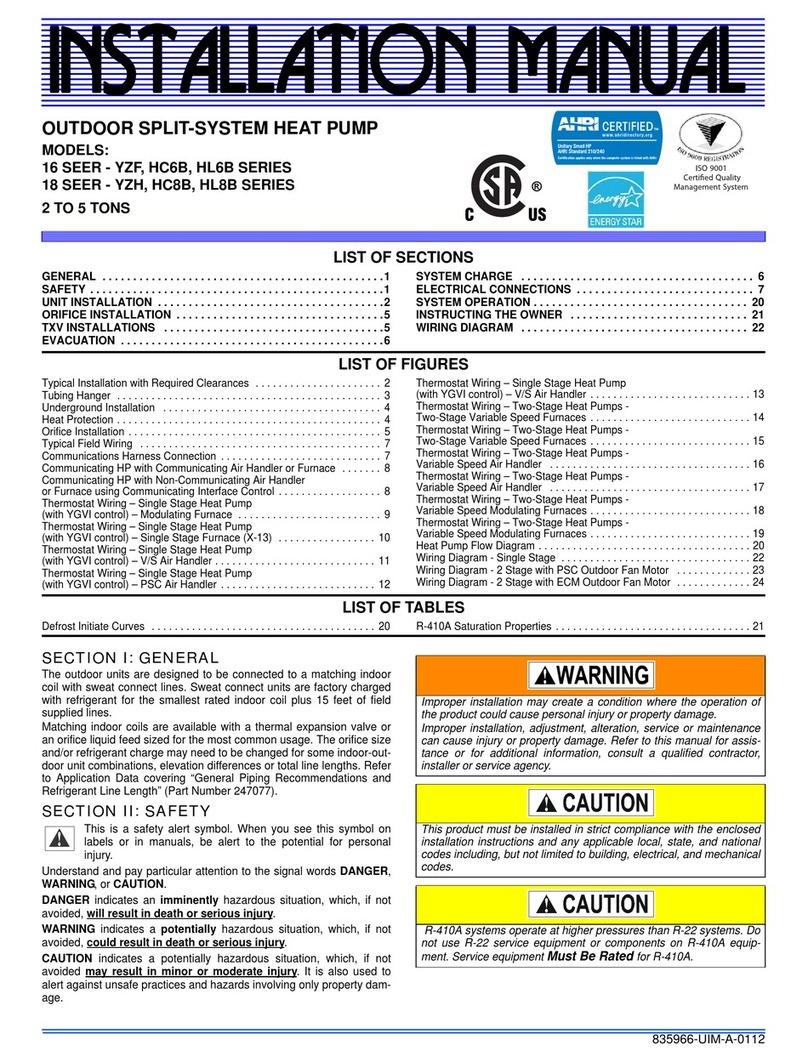

LIST OF SECTIONS

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

SAFETY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

MODEL NUMBER NOMENCLATURE . . . . . . . . . . . . . . . . . . . . . . . 2

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

AIRFLOW PERFORMANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

TYPICAL WIRING DIAGRAMS . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

START UP SHEET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

LIST OF FIGURES

Component Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Unit 4 Point Load Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Bottom Duct Dimensions (in.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Rear Duct Dimensions (in.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Typical Field Control Wiring Diagram for Heat Pump Models . . . . . . 7

Typical Field Power Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . 7

Single Point Wiring Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Demand Defrost Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Measuring External Static Pressure . . . . . . . . . . . . . . . . . . . . . . . . .16

Connection Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Ladder Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .19

R-410A Quick Reference Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

LIST OF TABLES

Unit Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Application Limitations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Weights and Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Unit Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Unit Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Electrical Data - 208/230-3-60 Single Source Power . . . . . . . . . . . . . 8

Single Point Wiring Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Electrical Data - 208-3-60 Multi Source Power . . . . . . . . . . . . . . . . . 9

Electrical Data - 230-3-60 Multi Source Power . . . . . . . . . . . . . . . . 10

Physical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Airflow Performance - Side Duct Application . . . . . . . . . . . . . . . . . .12

Airflow Performance - Bottom Duct Application . . . . . . . . . . . . . . . .13

Electric Heat Minimum Supply Air . . . . . . . . . . . . . . . . . . . . . . . . . .13

Electric Heat Multipliers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Additional Static Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Demand Defrost Selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Test Pins . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Fault Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Thermostat Signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

SECTION I: GENERAL INFORMATION

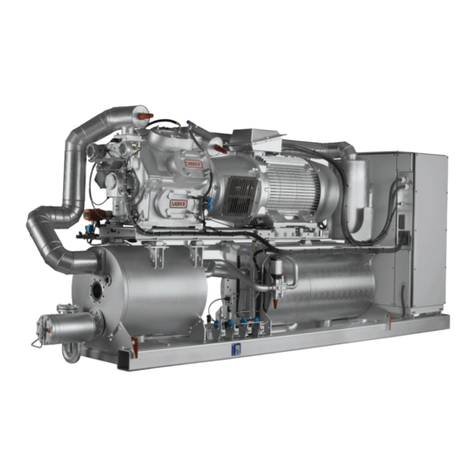

PHE units are factory assembled heat pumps designed for outdoor

installation on a rooftop or a slab. Field-installed optional electric heater

accessories are available to provide supplemental electric heat com-

bined with electric cooling and heating.

The units are completely assembled on rigid, removable base rails. All

piping, refrigerant charge, and electrical wiring is factory installed and

tested. The units require only electric power condensate drain and duct

connections at the point of installation.

SECTION II: SAFETY

This is a safety alert symbol. When you see this symbol on

labels or in manuals, be alert to the potential for personal

injury.

Understand and pay particular attention to the signal words DANGER,

WARNING, or CAUTION.

DANGER indicates an imminently hazardous situation, which, if not

avoided, will result in death or serious injury.

WARNING indicates a potentially hazardous situation, which, if not

avoided, could result in death or serious injury.

CAUTION indicates a potentially hazardous situation, which, if not

avoided may result in minor or moderate injury. It is also used to

alert against unsafe practices and hazards involving only property dam-

age.

WARNING

Improper installation may create a condition where the operation of

the product could cause personal injury or property damage.

Improper installation, adjustment, alteration, service or maintenance

can cause injury or property damage. Failure to carefully read and

follow all instructions in this manual can result in furnace mal-

function, death, personal injury and/or property damage. Only a

qualified contractor, installer or service agency should install this

product.

CAUTION

This product must be installed in strict compliance with the installa-

tion instructions and any applicable local, state, and national codes

including, but not limited to building, electrical, and mechanical

codes.

!

!