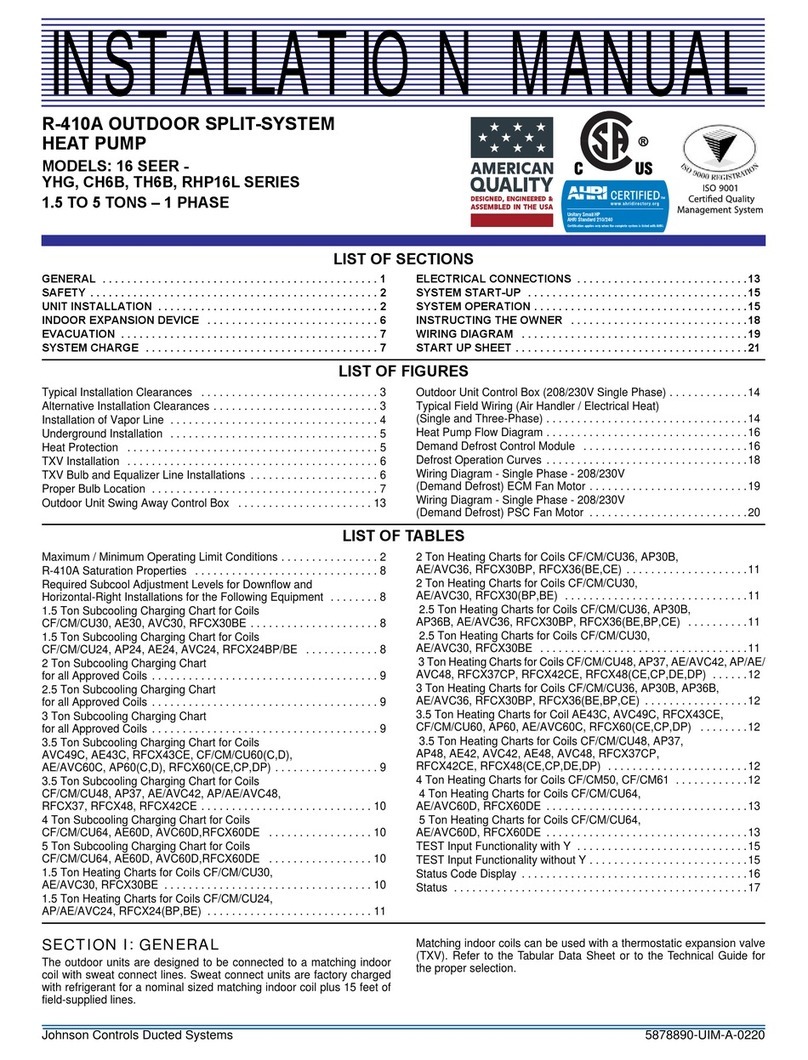

1062444-YIM-A-0913

10 Johnson Controls Unitary Products

Refrigerant Mains

Line Sizing

When sizing refrigerant pipe for a split-system air conditioner,

check the following:

1. Suction line pressure drop due to friction.

2. Liquid line pressure drop due to friction.

3. Suction line velocity for oil return.

4. Liquid line pressure drop due to vertical rise. For certain

piping arrangements, different sizes of suction line pipe

may have to be used. The velocity of the refrigerant vapor

must always be great enough to carry the oil back to the

compressor.

5. Evaporator Located Below Condenser - On a split

system where the evaporator blower is located below the

condenser, the suction line must be sized for both pressure

drop and for oil return.

6. Condenser Located Below Evaporator - When the

condenser is located below the evaporator blower, the

liquid line must be designed for the pressure drop due to

both friction loss and vertical rise. If the pressure drop due

to vertical rise and friction exceeds 60 psi, some refrigerant

will flash before it reaches the thermal expansion valve.

Flash gas:

1. Increases the liquid line pressure loss due to friction that in

turn causes further flashing.

2. Reduces the capacity of the refrigerant control device

which starves the evaporator.

3. Erodes the seat of the refrigerant control device.

4. Causes erratic control of the refrigerant entering the

evaporator.

Take Adequate Precautions

Many service problems can be avoided by taking adequate

precautions to provide an internally clean and dry system and

by using procedures and materials that conform to established

standards.

Use hard drawn copper tubing where no appreciable amount of

bending around pipes or other obstructions is necessary. If soft

copper is used, care should be taken to avoid sharp bends that

may cause a restriction. Pack fiberglass insulation and a

sealing material such as permagum around refrigerant lines

where they penetrate a wall to reduce vibrations and to retain

some flexibility.

Support all tubing at minimum intervals with suitable hangers,

brackets or clamps.

Braze all copper-to-copper joints with Silfos-5 or equivalent

brazing material. Do not use soft solder. Insulate all suction

lines with a minimum of 1/2" ARMAFLEX or equivalent that

meets local codes. Liquid lines exposed to direct sunlight and/

or high temperatures must also be insulated. Never solder

suction and liquid lines together. They can be taped together for

convenience and support purposes, but they must be

completely insulated from each other.

The liquid and suction service ports on the condenser section

permit leak testing, evacuation, and partial charging of the field

piping and the evaporator without disturbing refrigerant stored

in the condenser during initial installation.

Before beginning installation of the main lines, be sure that the

evaporator section has not developed a leak in transit. Check

pressure at the Schrader valve located on the header of each

coil. If pressure still exists in the system, it can be assumed to

be leak free. If pressure DOES NOT exist the section will need

to be repaired before evacuation and charging is performed.

A filter-drier MUST be field-installed in the liquid line of every

system to prevent dirt and moisture from damaging the system.

Properly sized filter-driers are shipped with each condensing

section.

NOTE: Installing a filter-drier does not eliminate the need for

the proper evacuation of a system before it is charged.

A field-installed moisture indicating sight-glass should be

installed in the liquid line(s) between the filter-drier and the

evaporator coil. The moisture indicating sight-glass can be used

to check for excess moisture in the system.

Both condenser and evaporator sections have copper sealing

disks brazed over the end of liquid and suction connections.

The temperature required to make or break a brazed joint is

high enough to cause oxidation of the copper unless an inert

atmosphere is provided.

NOTE: Dry nitrogen should flow through the system at all times

when heat is being applied and until the joint has

This Split-System (Air Condensing / Air Handling) unit is

one component of an entire system. As such it requires

specific application considerations with regard to the

rest of the system (air handling unit, duct design,

condensing unit, refrigerant piping and control scheme).

Failure to properly apply this equipment with the rest of

the system may result in premature failure and/or

reduced performance / increased costs. Warranty

coverage specifically excludes failures due to improper

application and Unitary Products specifically disclaims

any liability resulting from improper application.

Please refer to the equipment Technical Guide,

Installation Manual and the piping applications bulletin

247077 or call the applications department for Unitary

Products @ 1-877-UPG-SERV for guidance.