This symbol refers to a hazard or unsafe practice which can result in severe personal injury or death.

This symbol refers to a hazard or unsafe practice which can result in personal injury or product or property damage.

In case of improper installation

The manufacturer shall in no way be responsible for improper installation or maintenance service, including failure to

follow the instructions in this document.

SPECIAL PRECAUTIONS

•Duringinstallation,connectbeforetherefrigerantsystemandthenthewiringone;proceedinthereverseorderwhen

removing the units.

ELECTRICAL SHOCK CAN CAUSE SEVERE PERSONAL INJURY OR DEATH. ONLY A QUALIFIED, EXPERIENCED

ELECTRICIANS SHOULD ATTEMPT TO WIRE THIS SYSTEM.

•Donotsupplypowertotheunituntilallwiringandtubingarecompletedorreconnectedandchecked,toensurethe

grounding.

•Highlydangerouselectricalvoltagesareusedinthissystem.Carefullyrefertothewiringdiagramandtheseinstructions

when wiring.

Improper connections and inadequate grounding can cause accidental injury and death.

•Groundtheunitfollowinglocalelectricalcodes.

•TheYellow/Greenwirecannotbeusedforanyconnectiondifferentfromthegroundconnection.

•Connectallwiringtightly.Loosewiringmaycauseoverheatingatconnectionpointsandapossiblefirehazard.

•Donotusemulti-corecablewhenwiringthepowersupplyandcontrollines.Useseparatecablesforeachtypeof

line.

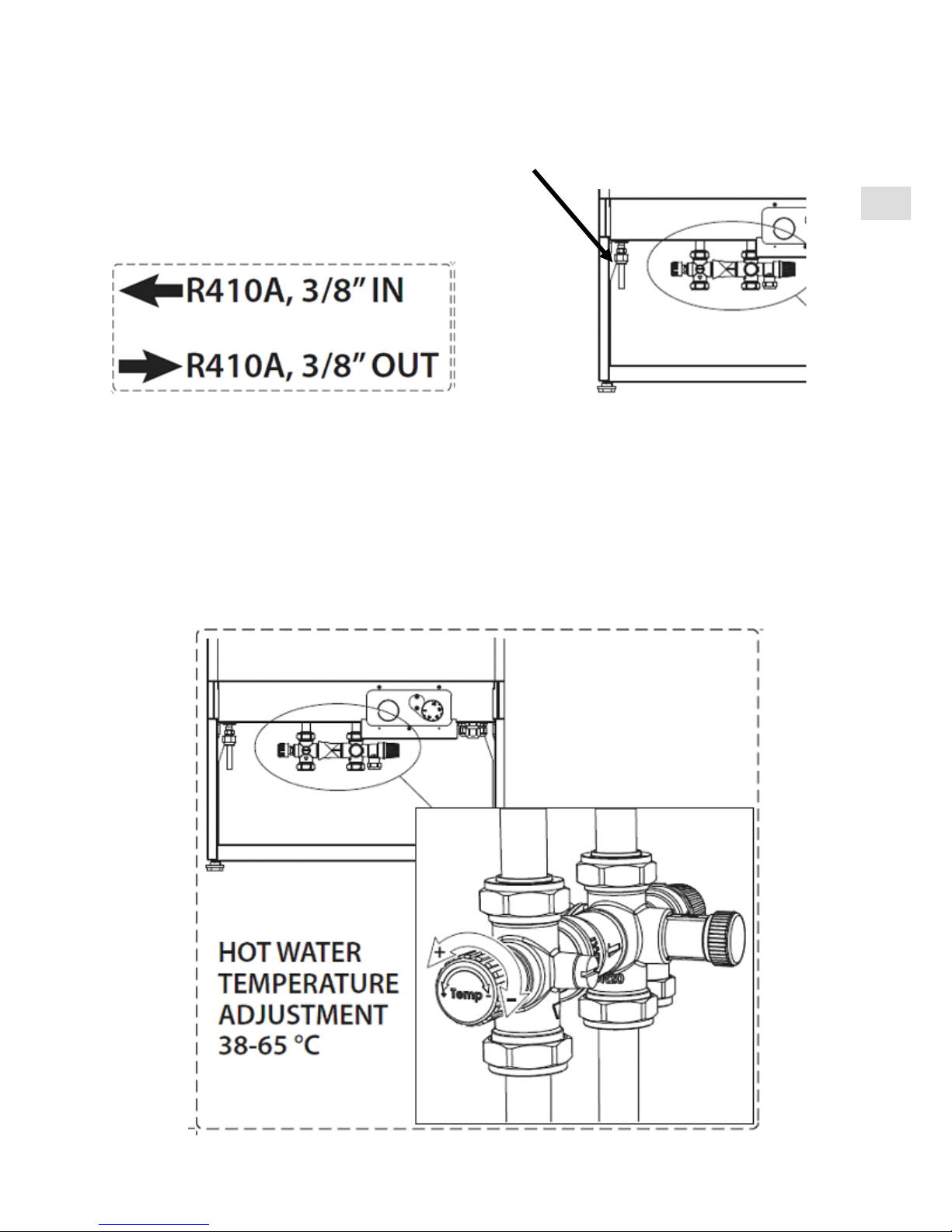

When connecting refrigerant tubing

•Keepalltubingrunsasshortaspossible,accordingly to the allowable distances from the outdoor unit (see manual).

•Usetheflaremethodforconnectingtubing.

•Applyrefrigerantlubricanttothematchingsurfacesoftheflareanduniontubesbeforeconnectingthem;screwby

hand and then tighten the nut with a torque wrench for a leak-free connection.

•Checkcarefullyforleaksbeforestartingthetestrun.

When servicing

•TurnthepowerOFFatthemainpowerboardbeforeopeningtheunittocheckorrepairelectricalpartsandwiring.

•Cleanupthesiteafterthework,rememberingtocheckthatnometalscrapsorbitsofwiringhavebeenleftinside

the unit being serviced.

•Ventilatetheroomduringtheinstallationortestingtherefrigerationsystem;makesurethat,aftertheinstallation,no

gas leaks are present, because this could produce toxic gas and dangerous if in contact with flames or heat-sources.

WARNING

CAUTION

WARNING When wiring

IMPORTANT!

Please read before installation

This system meets strict safety and operating standards.

Fortheinstallerorserviceperson,itisimportanttoinstallorservicethesystemsothatitoperatessafelyandefficiently.

For safe installation and trouble-free operation, you must:

•Carefullyreadthisinstructionbookletbeforebeginning.

•Followeachinstallationorrepairstepexactlyasshown.

•Observealllocal,stateandnationalelectricalcodes.

•Paycloseattentiontoallwarningandcautionnoticesgiveninthismanual.

•Theunitmustbesuppliedwithadedicatedelectricalline.