P/N IM-520/MH Rev. E 6

© 2017 Johnson Controls. All rights reserved. All specifications and other information

shown were current as of document revision date and are subject to change without notice.

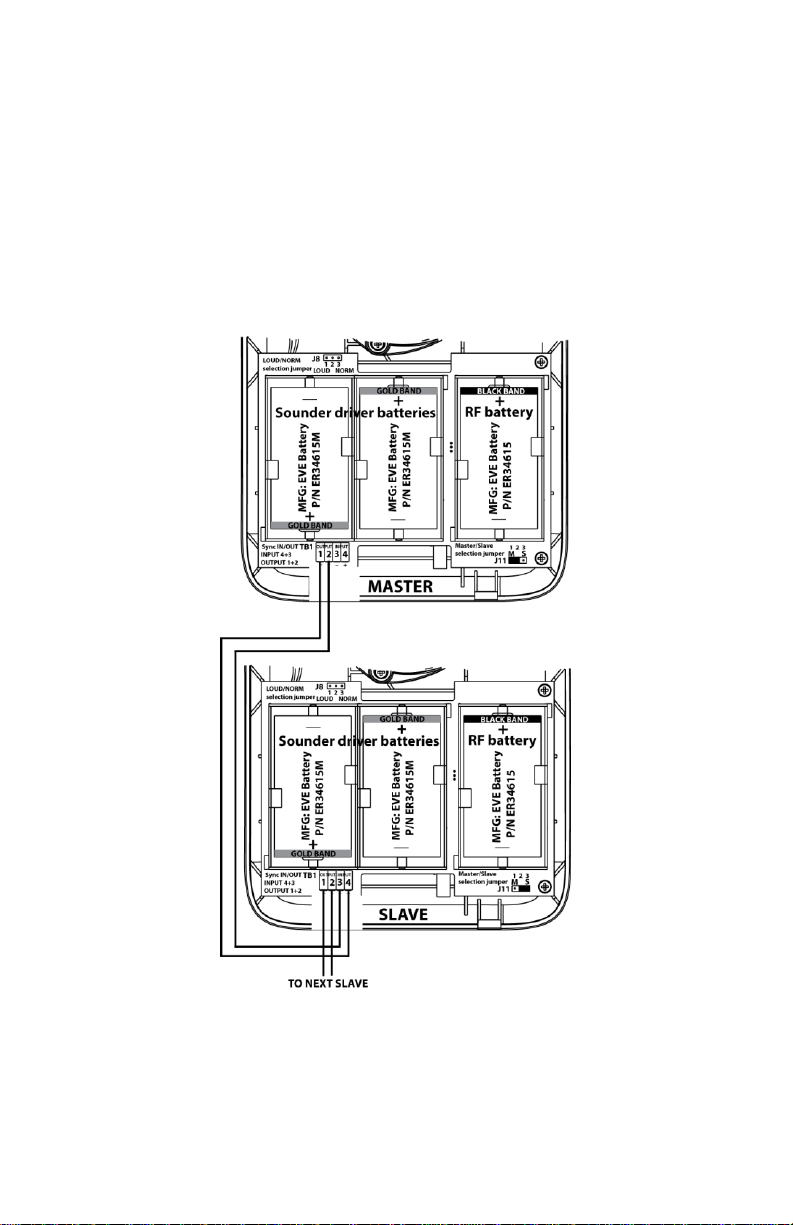

line slaves synchronized to it. If the original master resumes control then the pseudo

master will resort back to slave mode.

Alarm Testing

The 520/MH sounders must be tested after installation, programming, battery replacement

and following any maintenance. NOTE: Before testing, notify the proper authorities that

maintenance is being performed and the system will be temporarily out of service.

A basic sounder test can be accomplished by performing the sound test described in this

manual. This test does not check for proper programming of zones to the sounder or

functionality of all circuitry. A full system test to activate the sounders via zones is mandatory

to test full functionality of the sounder.

To test the sounder perform the following:

1. Activate an alarm from a device whose zone matches a zone programmed into the

sounder.

2. Verify activation of the sounder and measure db output at the desired location.

3. Verify the sounder operates for a minimum of 60 seconds.

4. Verify no troubles are received from the sounder during the alarm test.

5. Reset the control panel and verify the sounder silences.

6. Verify no troubles are received from the sounder after the alarm test.

7. Repeat the above for each sounder.

A failure of any sounder to successfully complete the alarm test should be checked and

repaired or replaced.

Low battery/Low battery2:

The model 520/MH periodically tests both the sounder driver and RF batteries for a low

battery condition. If a low battery is detected a trouble condition is transmitted and repeated

every 90 seconds. The RF and sounder batteries send two uniquely identified low battery

troubles. If the RF battery is low a low battery trouble will be present on the panel. If the

sounder driver batteries are low a low battery2 trouble signal will be present on the control

panel. If more than one type of trouble exists, all will be repeated in increments of 90 seconds.

Always replace the low battery with a new one. Refer to the Battery Installation and

Replacement section for instructions on battery replacement.

Battery Installation and Replacement:

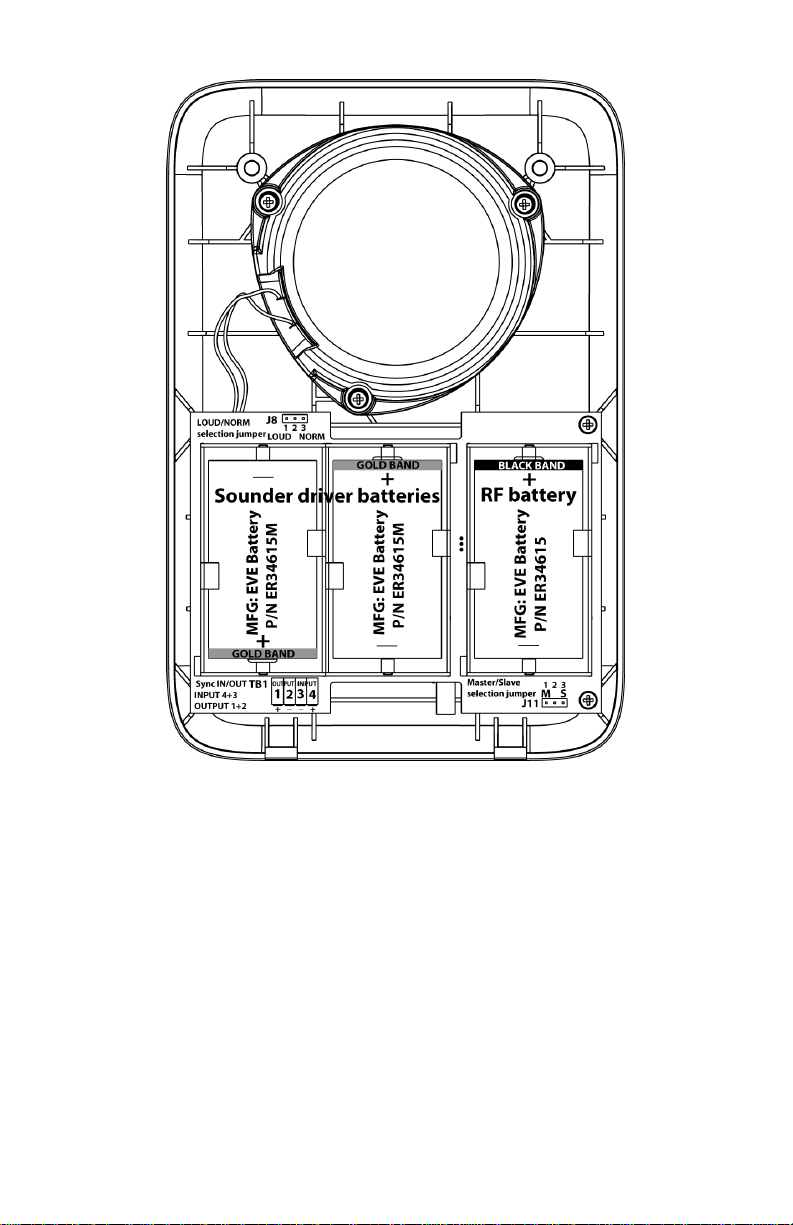

Warning: Always install new battery/batteries of one of the approved types as listed in

the Specifications section of this manual and the product label. The RF and sounder

driver batteries are two different part numbers. Be sure to install the correct p/n battery

in the appropriate holder(s). Observe correct polarity as marked in the battery holders.

To replace the battery:

1. Place the Control Panel in Test mode to prevent any unwanted alarms.

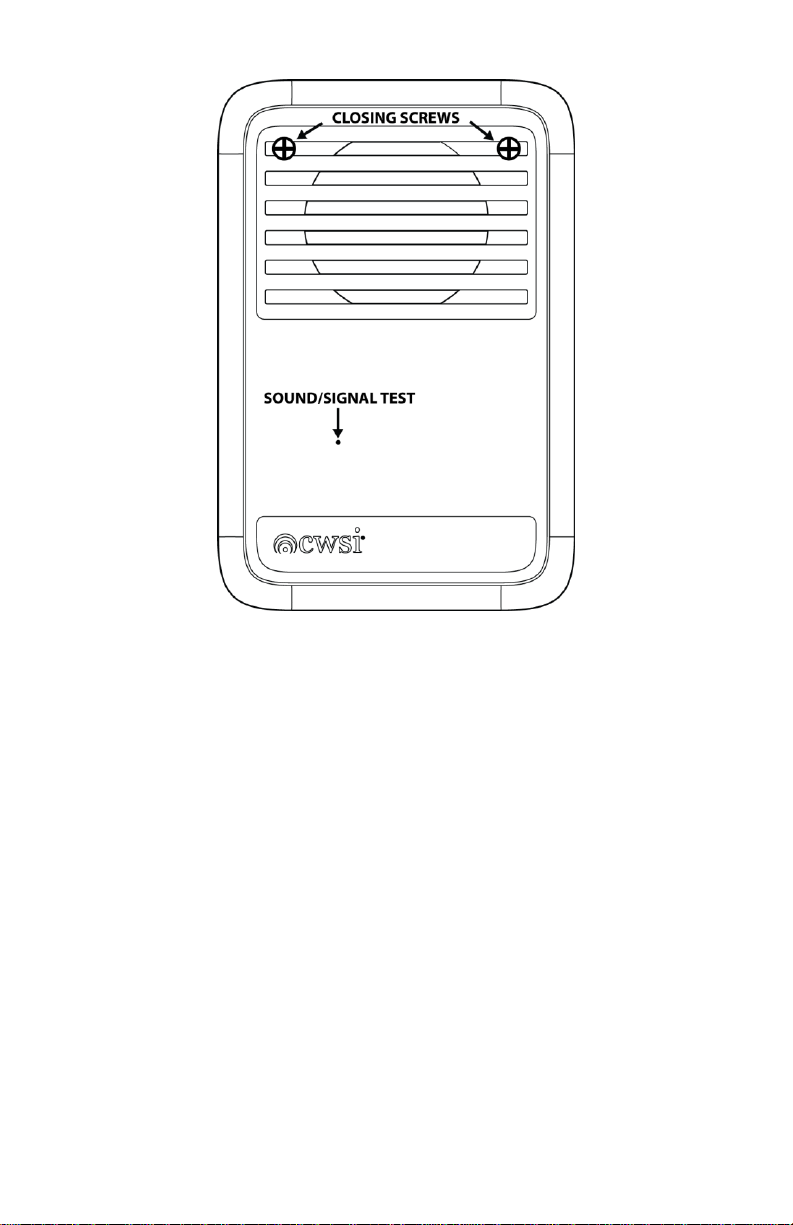

2. Remove the front of the 520/MH by removing the two closing screws then separate the

front and back starting at the top of the case. Lift off the front then remove the old battery/

batteries and dispose of properly.

3. To insure proper power down sequence, wait a minimum of 20 seconds before installing

a new battery.

4. Install new battery/batteries in the battery compartment following the polarity diagram

inside the compartment. When replacing the sounder driver batteries always replace

both batteries with new ones. A power up reset trouble signal should be indicated on the

Control Panel within 30 seconds. A tamper trouble will also be indicated if the front cover is

not attached to the base.

Note: When changing only the sounder driver batteries you must remove and reinstall

the RF battery after replacing the sounder driver batteries in order to reset the

lowbattery2 trouble signal from the memory of the 520/MH. The RF battery does not