AquaTTM Standard Electric marine toilet- Instruction Manual

English

Mounting

Before starting the assembly, read the complete mounting instruction first.

You need:

• Stainless steel bolts: 4 pcs, 8mm (5/16") diameter of length to suit the

thickness of the mounting surface.

• Stainless steel nuts: 4 pcs preferably self-locking. If you do not use

self-locking nuts you need to add locking compound on the

screws-/ nuts.

• Stainless steel washers: 4 pcs.

• Drill: Diameter 9mm.

• Silicone sealant, white.

If you do not use self-locking nuts, you will need some nutlocking

compound

1. Put the toilet in the selected position. Using the holes in the base as a

guide, mark the positions for the 4 bolt holes on the mounting surface.

Remove the toilet and drill 4 vertical holes, with a diameter of 9mm,

through the mounting surface.

2. Apply the white silicone sealant to the outer rim of the bottom base.

3. Put the toilets on its place and tighten the fastenings securely. If you

are not using self-locking nuts, use nutlocking compound.

4. Use the sealant around the base, towards the floor.

Operating instructions

The toilet is one of the most used pieces of equipment on your boat.

Correct operation of the toilet is essential for the safety and comfort of your

crew and craft.

Using the toilet

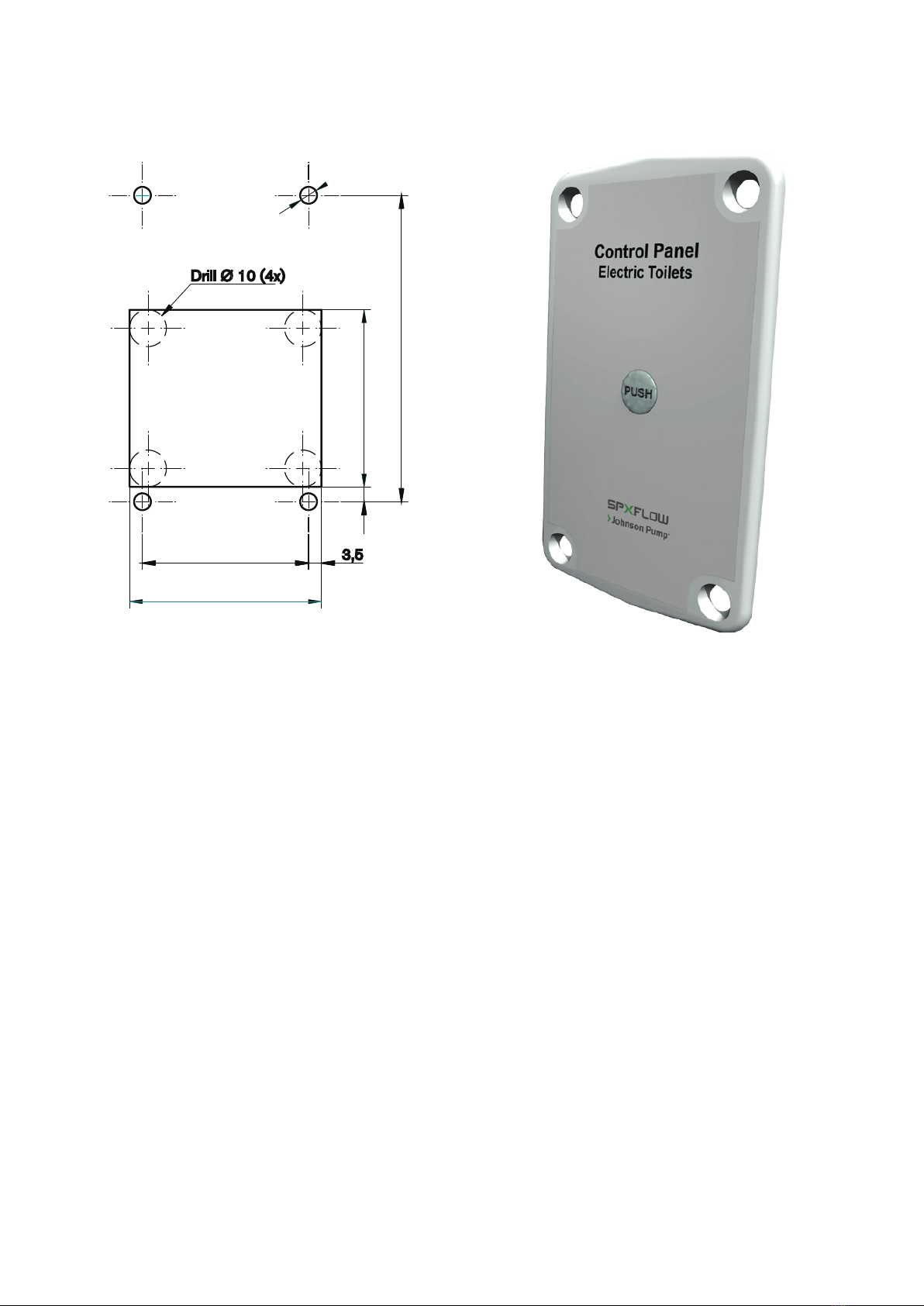

Control panel

The panel controls the rinse and the discharge, by one button.

• Button 1: One function, discharge and rinse.

Normal Use

1. Ensure that the inlet and outlet valves are open

2. Push the button switch to operate flush until the bowl is thoroughly

rinsed and the discharge pump has ejected the water from the base

of the bowl.

• If the toilet has not been used for a while, and the bowl is dry, it’s

recommended to operate the pumps for a few seconds so the bowl

gets wet. This is for preventing the toilet paper to become compact at

the bottom of the bowl.

• The toilet can macerate organic waste and toilet paper, but it can not

destroy rugs, sanitary nappies or hard and solid objects from different

nature

• If the pump does not discharge and the bowl begins to fill, partially

close the toilet intake valve until the bowl is completely empty.

Operate than for a few seconds with both valves open, so that the

toilet and the whole discharge system may be completely emptied out.

• After each operation, close both inlet and discharge valves.

• To drain for winterization, close the inlet valve and operate for a few

seconds until water is completely empty.

After use:

• Shut both seacocks

NOTE: Do not put any of the following into the toilet: Sanitary

Towels, Wet Strength Tissues, Cotton Wool, Cigarettes, Matches,

Chewing Gum or any solid objects, Petrol, Diesel, Oil, Solvents of

any kind or water more than hand warm.

A rule of thumb: Do not put anything in the toilet unless it has

passed through your body, except for toilet paper.

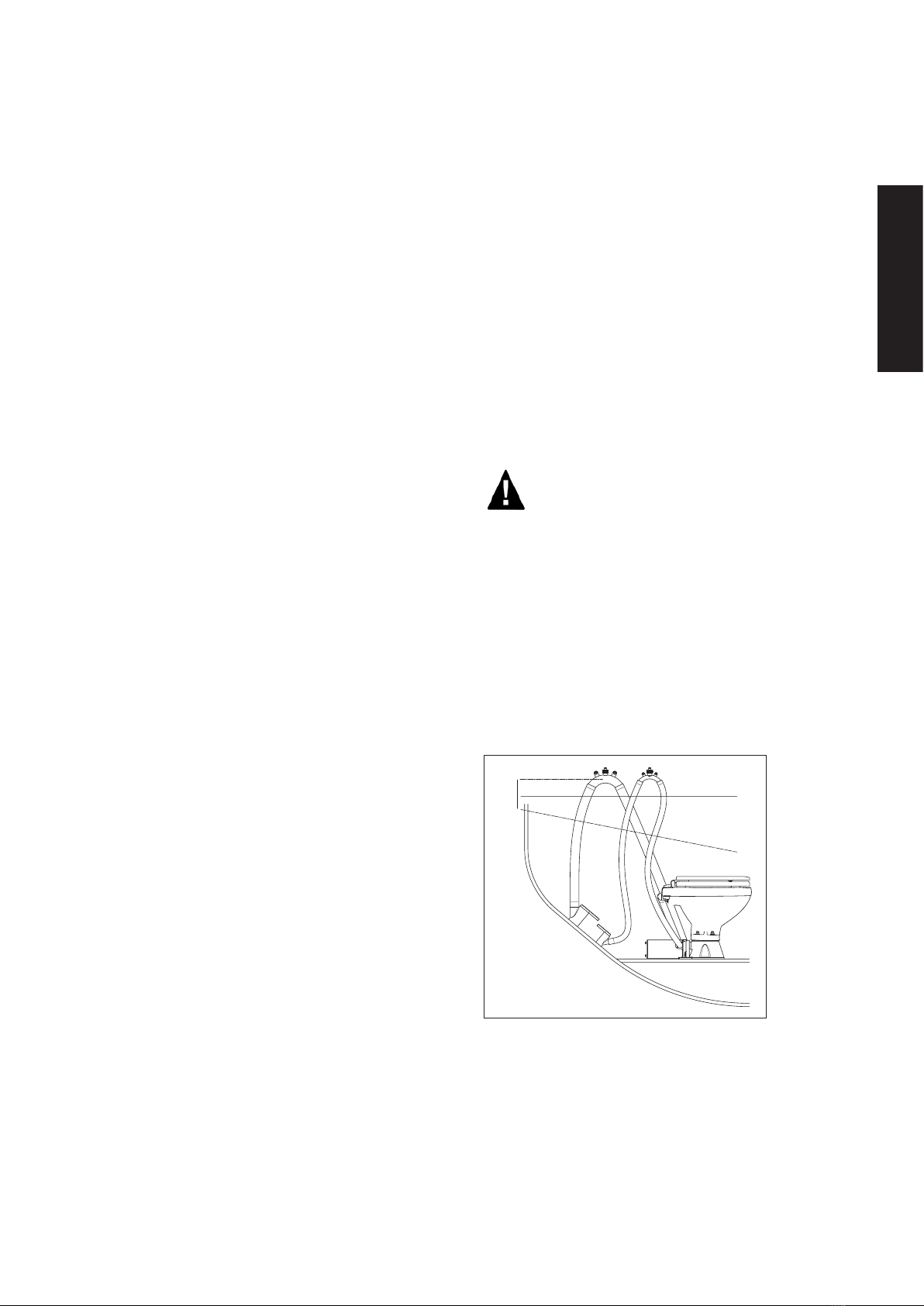

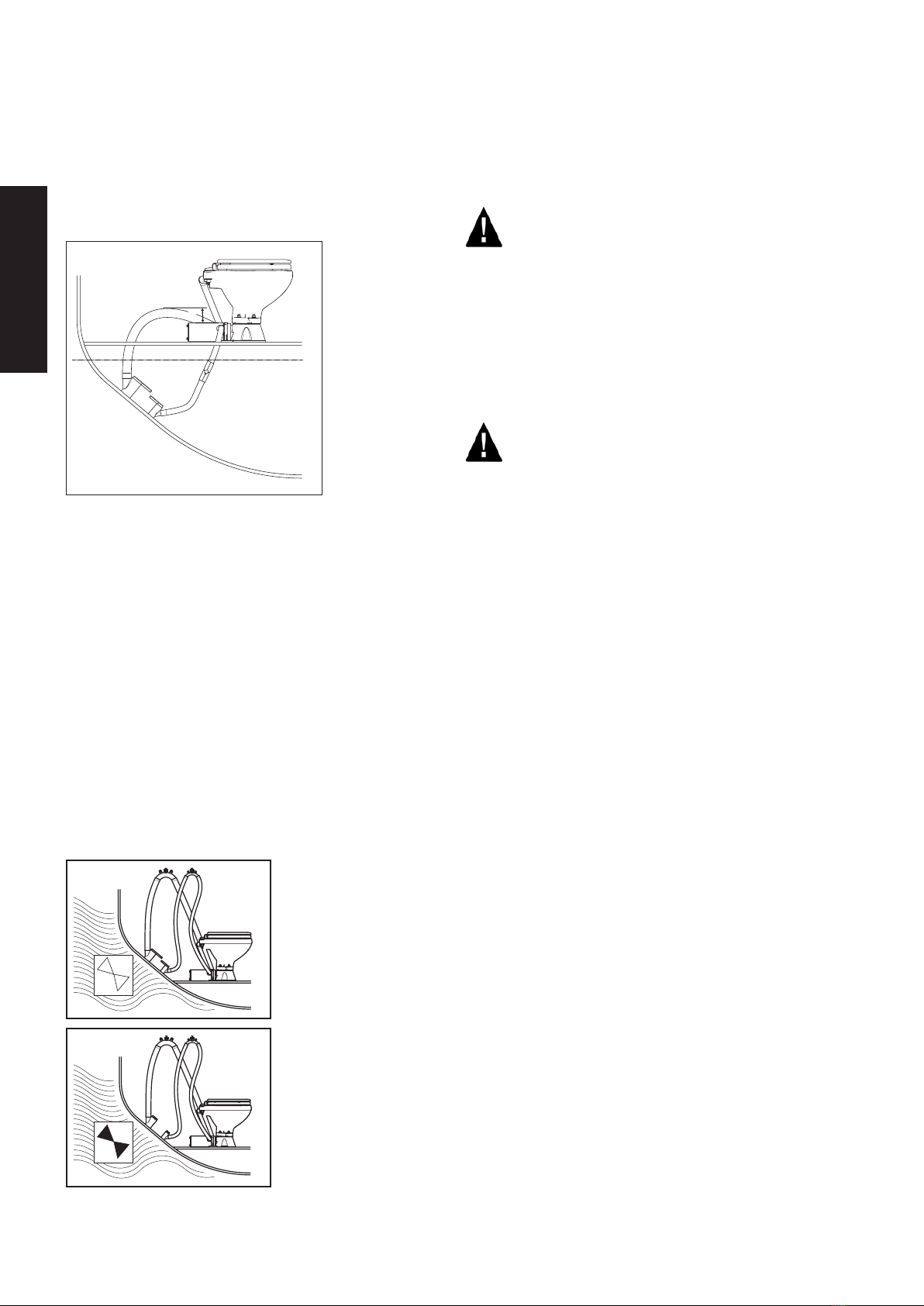

Hazard Risk:

ACCIDENTAL DAMAGE. If the toilet is connected to ANY through-hull

fittings that are below the waterline at any time, and if the toilet or pipework

is damaged, water may flood in, causing the craft to sink, which may result

in loss of life. Therefore, after every usage; both seacocks (or secondary

valves) MUST be shut. Whenever your craft is unattended, even if only for a

very short period of time, both seacocks (even if secondary valves are fitted)

MUST be shut. Ensure that ALL users understand how to operate the toilet

system cor¬rectly and safely, including seacocks and secondary valves.

Take special care to instruct children, the elderly and visitors ABSOLUTELY

SHUT SEACOCKS!

Cleaning

A regular flushing with clean (sea)-water represents one of the most

effective methods to keep the toilet clean and good smelling.

• To clean the bowl, use any liquid or cream ceramic cleaner

• To clean the rest of the toilet, including the seat and lid, use a non-

abrasive liquid cleaner Polish with a dry cloth only.

• To disinfect the toilet, use a liquid disinfectant diluted in accordance

with the manufacturer’s instructions. It is possible to apply it to all

parts of the toilet using a sponge or soft brush as necessary.

• After applying any cleaning or disinfecting agent, always flush well.

DO NOT ALLOW THESE AGENTS TO STAND IN THE SYSTEM

Electric Connections

Connect the wires from the pump as follows:

Red

Red

Discharge/Rinse pump

Red

Black

Fuse

Panel Red (upper wire on switch) to positive (+) battery via one fuse

Panel Red (lower wire on switch) to toilet pump red

Toilet pump Black to battery negative (-)

To install the switch panel, use the template or dimensions from the

template. Also, drill four appropriate sized holes for the fasteners selected

to secure the switch panel to its mounting surface. Use the enclosed

template, see page 27.

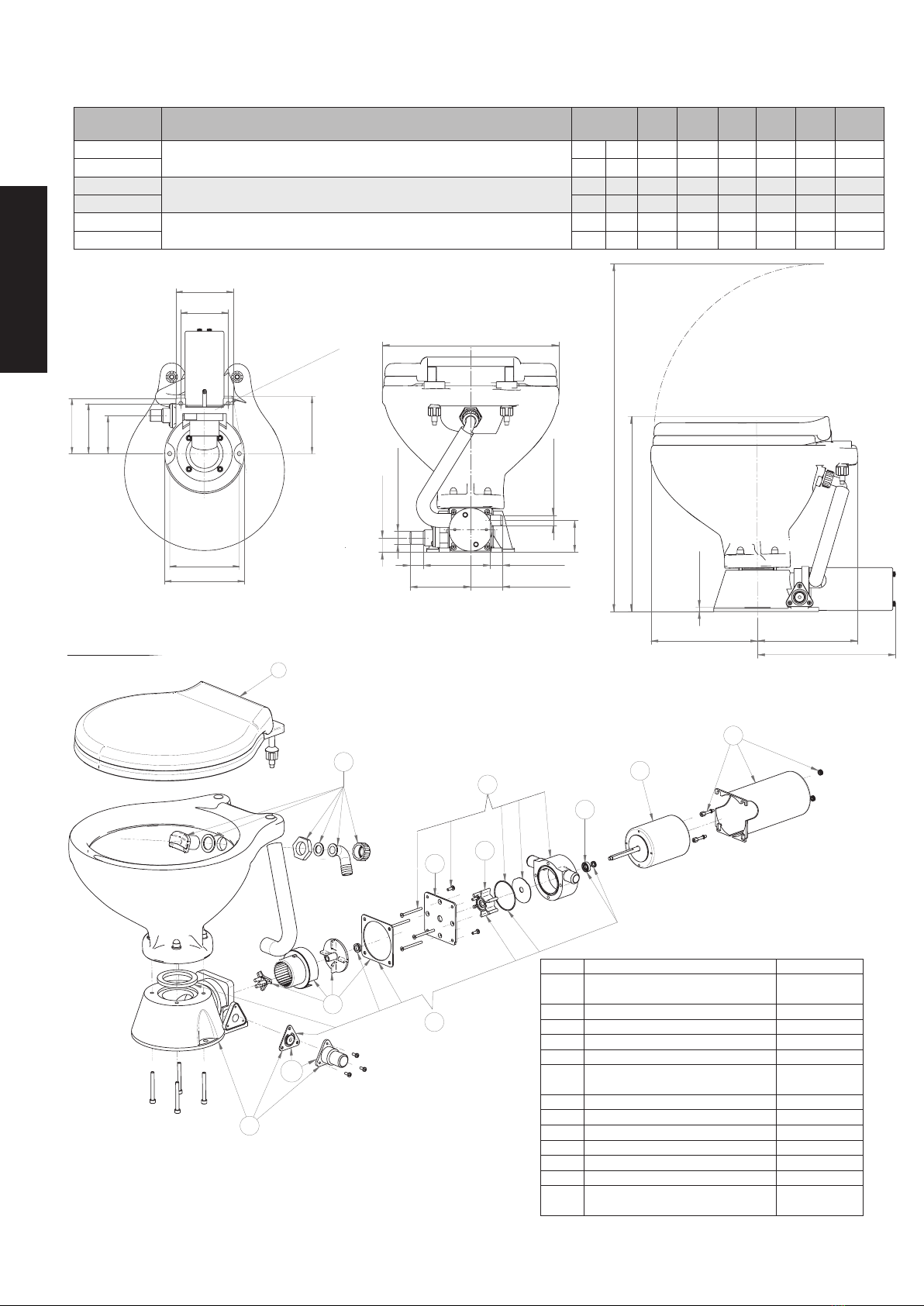

Wire size per feet and meter of run

Voltage Fuse

size

0’-10’ 10’-15’ 15’-25’ 25’-40’ 40’-60’

0m-3m 3m-4,6m 4,6m-7,6m 7,6m-12,2m 12,2m-18,3m

12V 25A #14 #14 #12 #10 #8

2,5 mm22,5 mm24 mm26 mm210 mm2

24V 20A #14 #14 #14 #14 #12

2,5 mm22,5 mm22,5 mm22,5 mm24 mm2

9

Original instructions