061920 © 2020 Jomar Valve • www.jomarvalve.com • P: (586) 268-1220 • F: (586) 979-8315

Note: Information subject to change without notice.

2

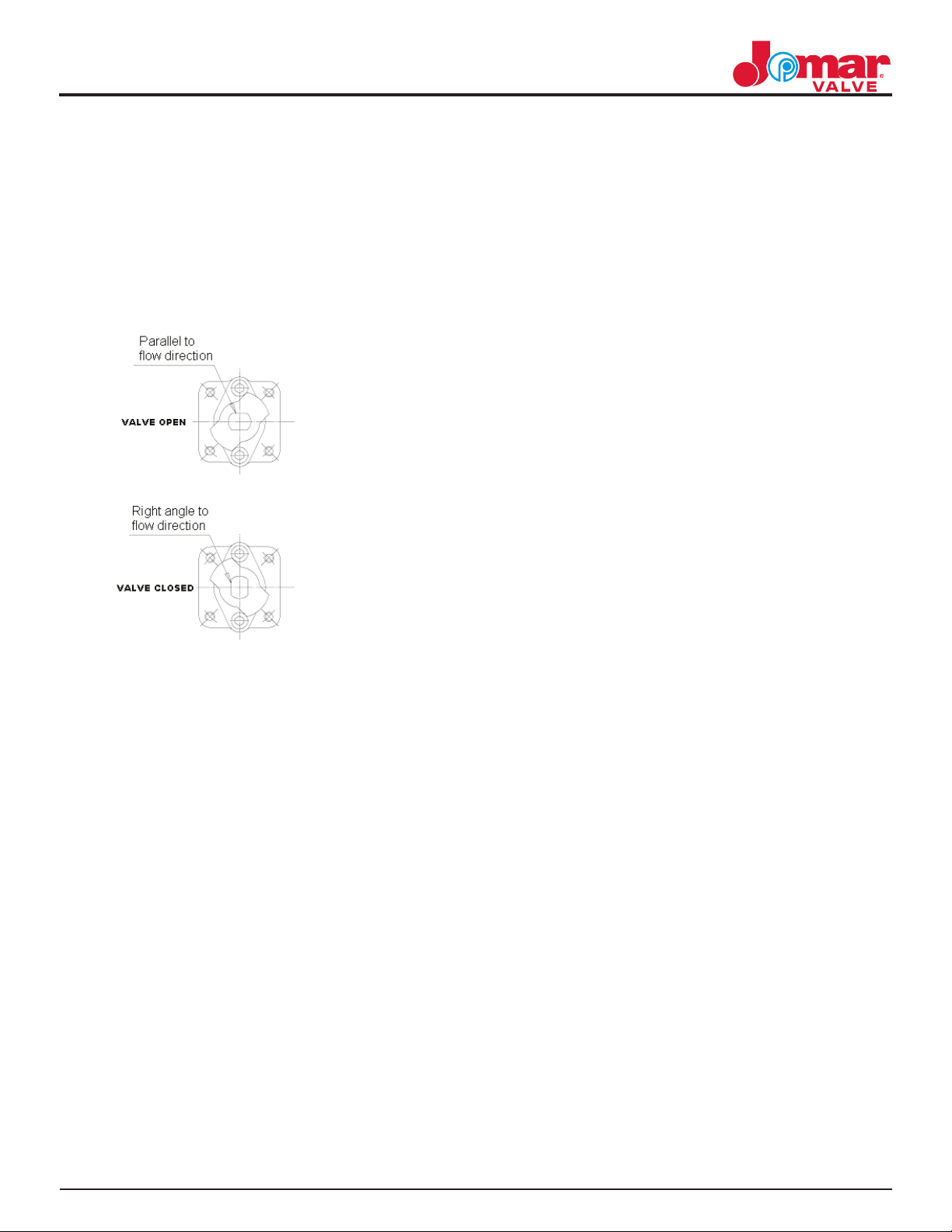

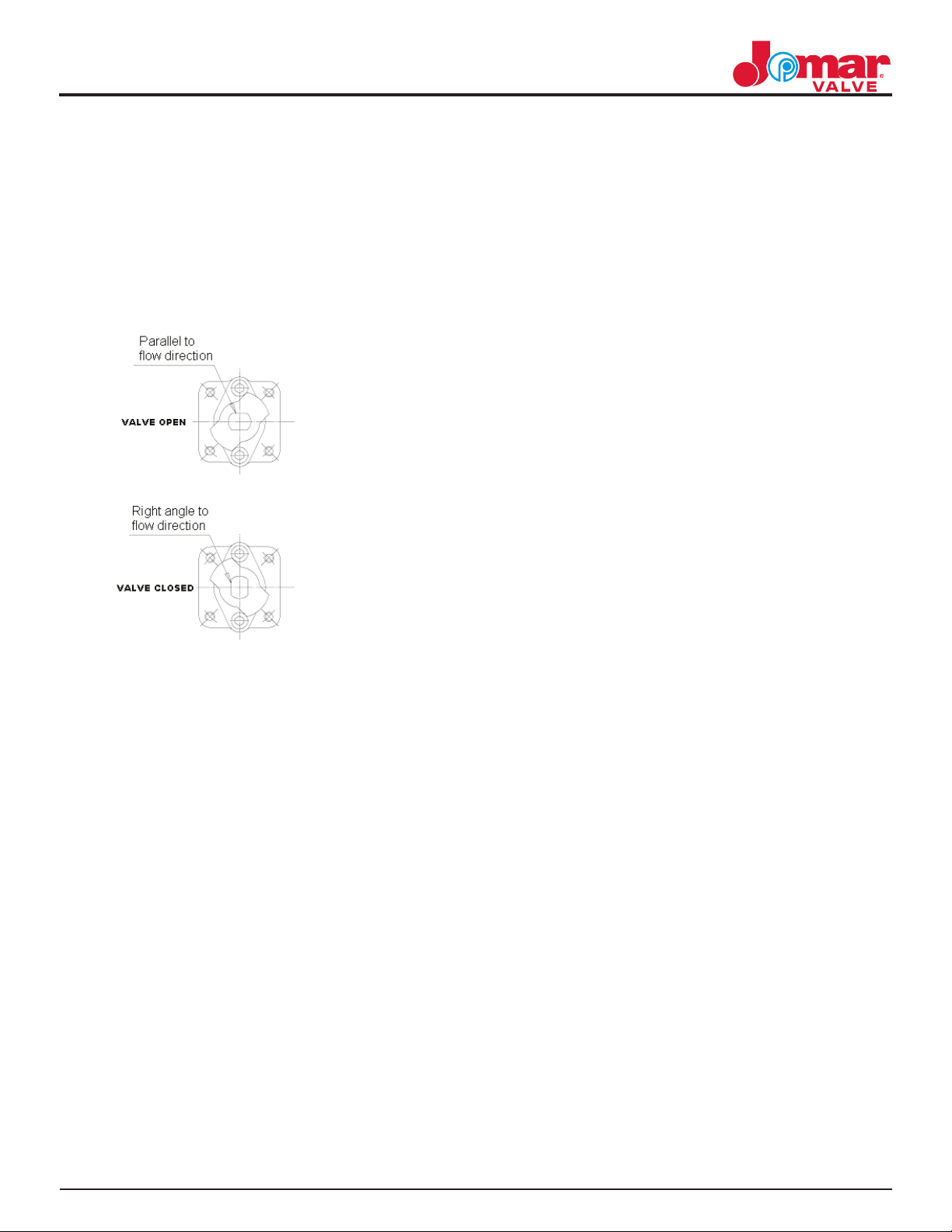

valve is open. If the handle is at right angles

to the pipeline, the valve is closed.

b. When the valve is operated with

removable handle, the user should ensure the

position of the valve, whether open or closed.

There is a mark at the top of stem for double

“D” type stem. Refer Fig 1 below showing how

to determine the valve’s position.

Fig-1

3. Maintenance

3.1 Maintenance frequency

The maintenance frequency is determined

by the valve’s application. User shall consider

the time interval depending on uid, ow

velocity, operational frequency, high-pressure

eect and high-temperature eect etc. Valves

should be operated at a minimum twice a

year.

3.2 Disassembly

a. To disassemble the valve, please follow

the procedure and drawings below.

1) Turn the valve fully open. Loosen No.

16-1 and 18, remove No. 14 handle and

No. 15 at washer.

2) Use pincer to take o snap ring. Turn

ball until half open. Remove No. 12 stop

plate.

3) Remove No. 11-1 gland bolts., remove

No. 10 gland ange.

4) Remove No. 17 Bolts using a ring

spanner. Remove No. 2 cap.

5) Take No. 6 body seal and No. 3-2 seat

out. Fully close ball and remove No. 4

ball and 3-1 seat.

6) Take No. 5 stem out by pushing No.

5 stem downward. Remove No. 8 stem

packing and No. 7 thrust washer.

7) Do not remove No. 19 & No. 20. Static

devices.

b. It is necessary to open the ball slightly

to drain the body cavity slowly. Be aware of

media trapped in the body cavity and take

necessary precautions for safe handling and

protect against exposure.

c. The ball cannot be taken out from valve

body if the ball is in the open or semi-open

position. The correct position to work on the

valve is with the ange end down.

d. To separate the valve body and cap,

undo the bolts symmetrically.

e. During and after assembly/disassembly,

take precaution not to damage the surface of

the ball.

3.3 Parts inspection, maintenance, and

replacement:

a. Check the surface of ball for marks.

If there is any damage on the surface, nd

out the root cause such as dirt, uid…etc. It

is important to avoid these damage factors

wherever possible.

b. If the ball surface is damaged at the

contact area of ball and ball seat the ball must

be re-surfaced. If it is damaged heavily, and

cannot be repaired, a new ball must be tted.

c. Inspect the surface of soft seats, and

replace if any damage or deformation is

evident.

d. The stem seal must be replaced after

disassembling the valve.

e. Repair kits are available by contacting

Jomar.