6English

!WARNING!

Theone-mansawmillmustnever

beusedifanyofthesafetydevices

or guards are missing, damaged

or out of function.

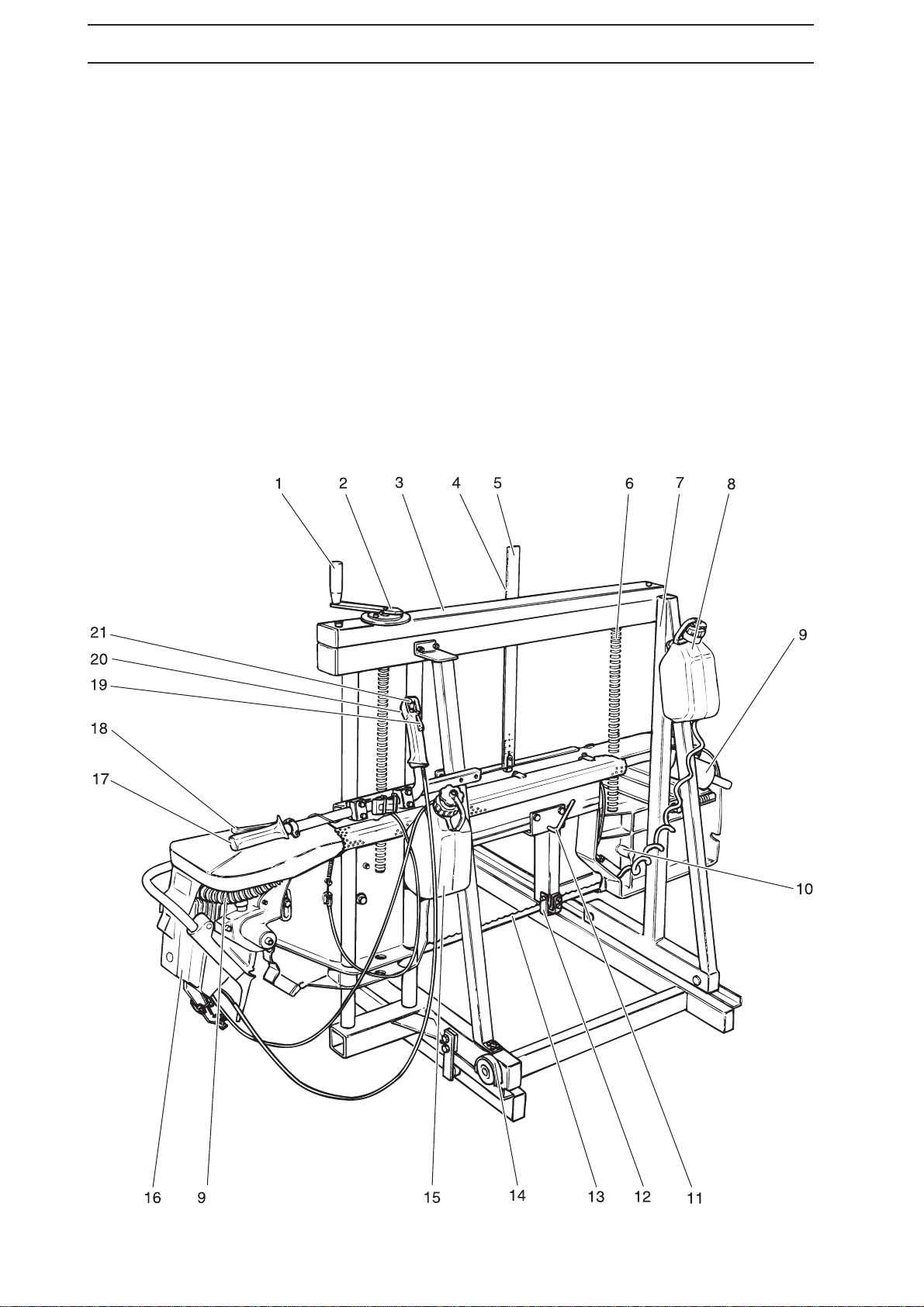

The sawmill is equipped with a number of safety

devicesandguardsdesigned to prevent accidents

from occurring when using the sawmill. These are

described under the general description of the

sawmill. See pages 14-15.

Thesafetydevicesandguardsalsorequireregular

checks and maintenance. These measures and

theintervallsatwhichthey aretobecarriedoutare

given under "Maintenance". See pages 30-44.

Safety when handling fuel

!WARNING!

The fuel used in the one-man

sawmill has the following

harzardous properties:

1. Liquid fuel emits poisonous gas

fumes and exhaust gases.

2. Can cause skin irritation.

3. Is extremely flammable.

The safety equipment of the one-

man sawmill Safety during operation

Thesafetyinstructionsthatapplywhenrunningthe

one-man sawmill are given where appropriate in

the section "General use" on pages 26-29.

Before and while using the sawmill, the operator

must observe the following safety precautions:

1. Checkthatallofthesafetydevicesandguards

are in place and are faultless.

2. Check that no fuel has been spilled outside

the tank or on the ground.

3. See to it that no unauthorised persons enter

the risk zone of the one-man sawmill.

4. Thestopsandthelockingdevicesrequiredfor

securing the log must be used in the intended

manner. See pages 27-29.

5. Adjust the blade guide so that it will be as

near to the log as possible. See page 27.

Specialsafetyregulationsapplytohandlingthefuel

used for running the one-man sawmill. These are

specified under "Fuelling" on pages 23-24.

5 m

3 m

3 m 3 m

SAFETY INSTRUCTIONS

Risk zone

The risk zone is shown in the figure to the right.

No unauthorised persons may be present within

the risk zone.

The risk zone must also be kept free of foreign

objects and the ground within the risk zone must

be even to prevent stumbling.

Users

The following applies to persons who use one-

man sawmill:

1. The user must have read and understood the

content of this user's manual.

2. The user must not be under the influence of

alcohol, medicin or be affected by fatigue.

3. Must be an adult.