www.joy-it.net

Pascalstr. 8 47506 Neukirchen-Vluyn

With the DIP switch 5 (SW5) you can set the direction of rotation of the motor.

If the switch is set to ON, it rotates clockwise, if the switch is set to OFF, it rotates

counterclockwise.

The setting is only accepted aer a restart of the unit.

DIP switch 6 (SW6) is used to select whether the internal smoothing function for

the input pulse signal should be activated. If the switch is set to ON, this means

that the smoothing function is enabled, if it is set to OFF, the Function disabled.

The setting is only accepted aer a restart of the unit.

DIP switch 7 (SW7) is used to select the input pulse mode. If the switch is set to

ON, the PUL/DIR mode is active, if it is OFF, the CW/CCW mode is active.

The setting is only accepted aer a restart of the unit.

With the DIP-switch 8 (SW8) you can activate or deactivate the step loss detec-

tion. If the switch is set to OFF, the step loss detection is activated, if the switch

is set to ON, it is deactivated.

The setting is only applied aer the unit has been restarted.

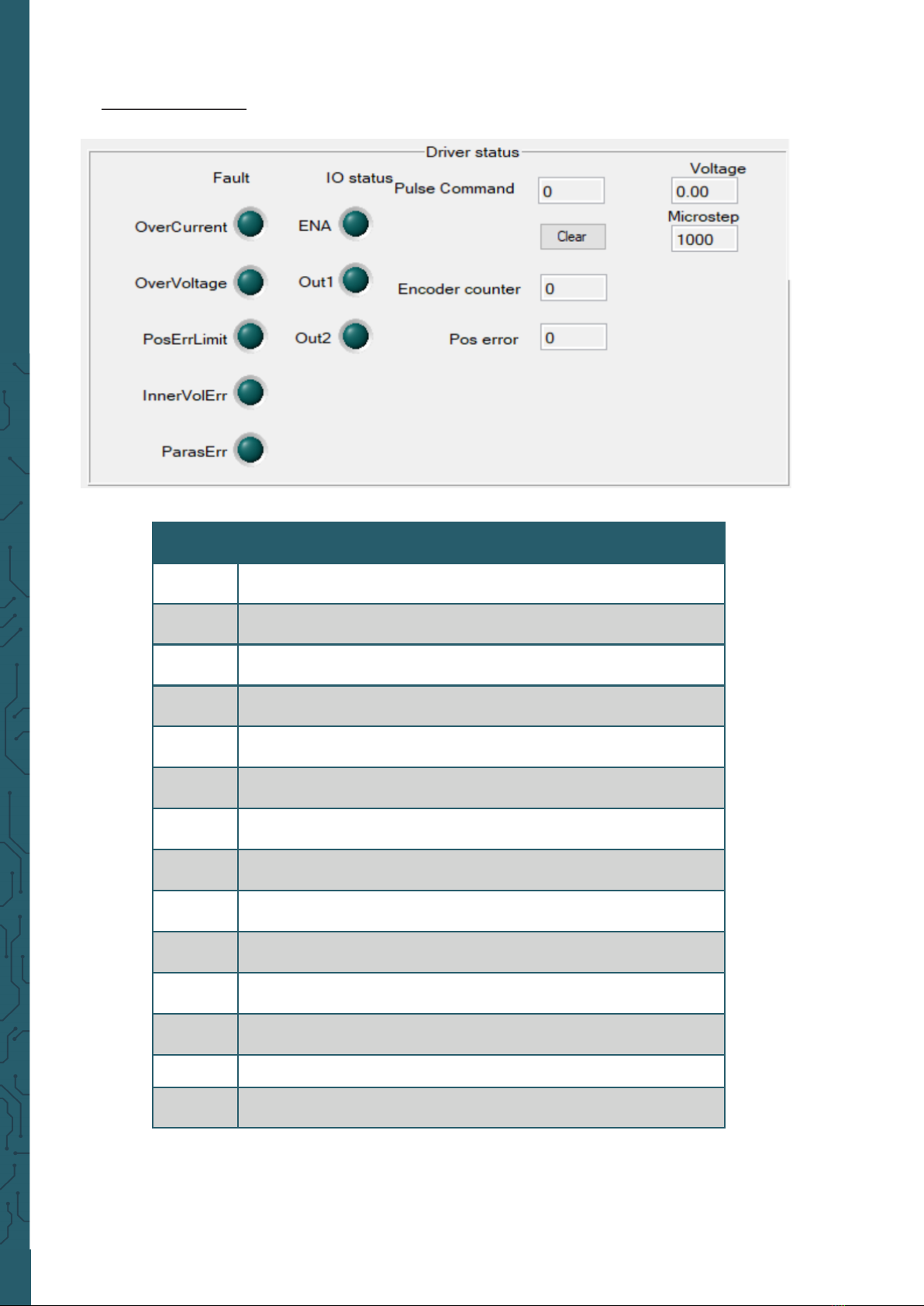

A green and a red LED are installed on the motor driver to indicate the current

status.

4. LED INDICATORS

Drive statusLED status

The green LED lights up Drive not active

The green LED flashes Drive operates normally

The red and green LEDs light

up Overcurrent

The red LED flashes twice and

the green once Overvoltage

The red LED flashes three

times and the green LED once

Incorrect internal driver

voltage

The red LED flashes four times

and the green LED once

Tracking error exceeds

the limit value

The red LED flashes five times

and the green LED once Encoder phase error