3

Table of Contents

TABLE OF CONTENTS................................................................................................................... 3

UNPACKING..........................................................................................................................................................................7

CLEANING ............................................................................................................................................................................7

PRIOR TO OPERATION .............................................................................................................................................................7

SET-UP AND ASSEMBLY ............................................................................................................... 8

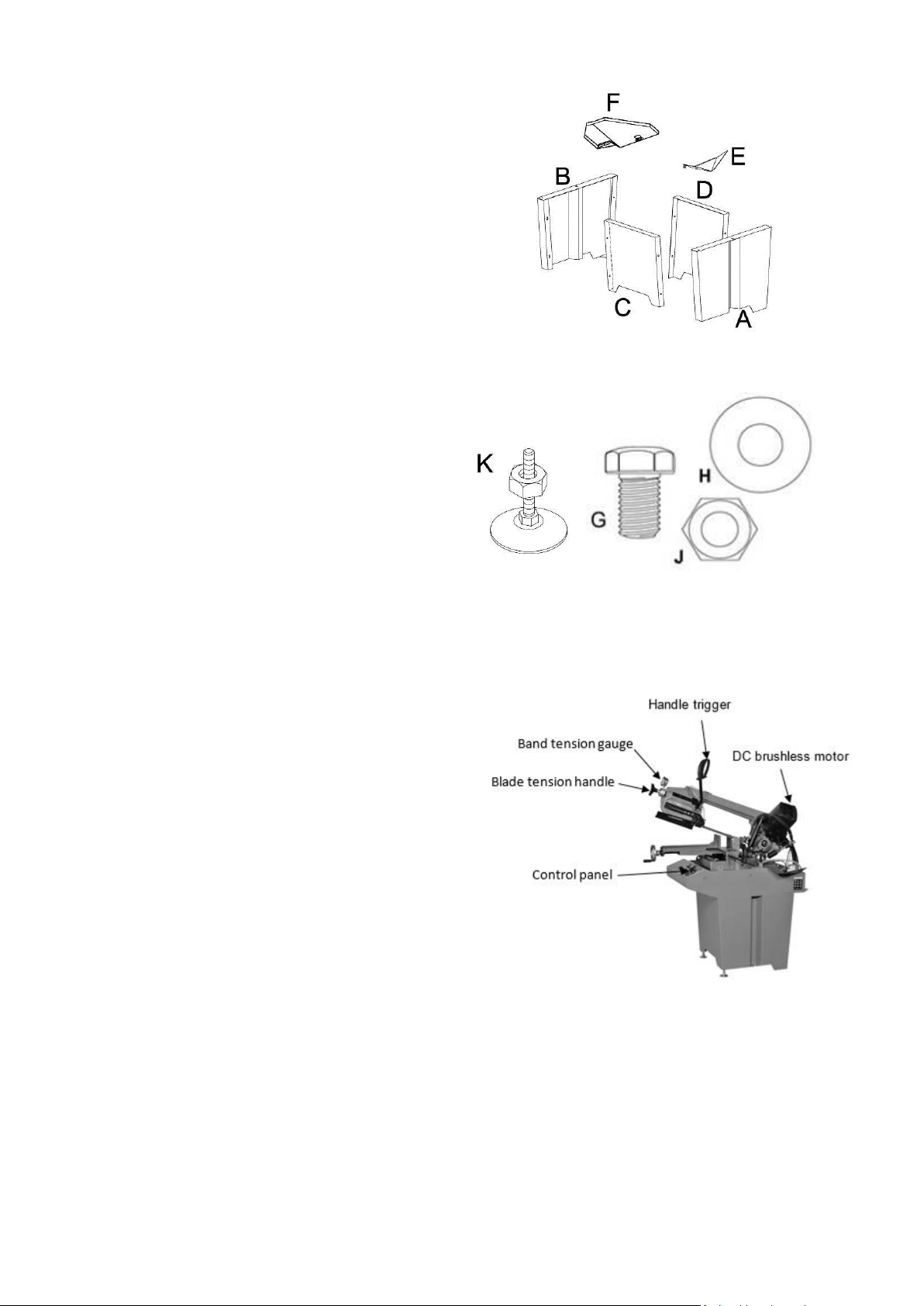

STAND.................................................................................................................................................................................8

HARDWARE ..........................................................................................................................................................................8

SAW HEAD ...........................................................................................................................................................................8

WORK STOP .........................................................................................................................................................................9

STAND ASSEMBLY ..................................................................................................................................................................9

MOUNTING SAW TO STAND.....................................................................................................................................................9

INSTALL THE EXTENSION TRAYS ...............................................................................................................................................10

MACHINE BASE ...................................................................................................................................................................10

COOLANT SYSTEM................................................................................................................................................................10

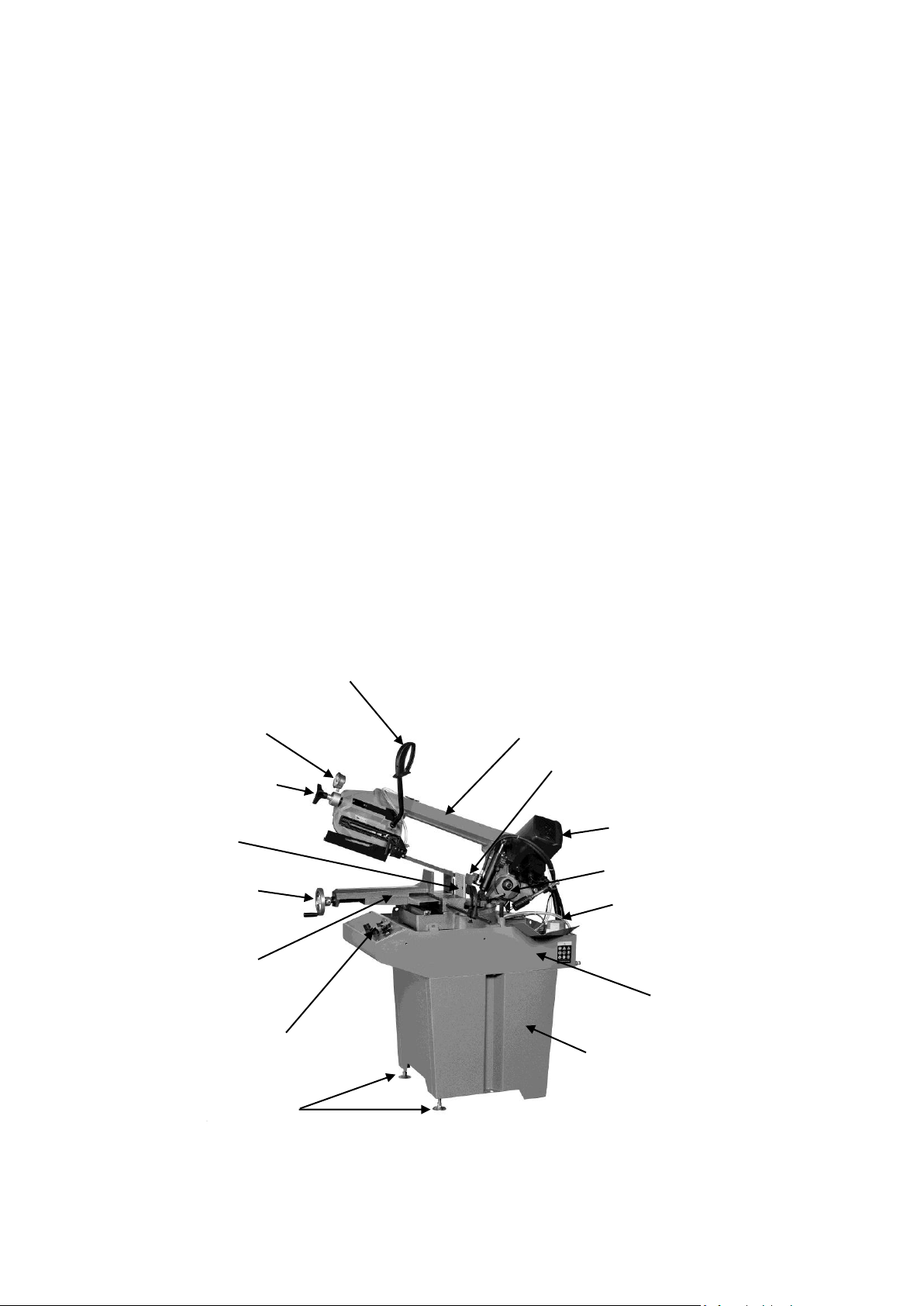

OPERATING CONTROLS ............................................................................................................. 11

OPERATION OF CONTROL PANEL.............................................................................................................................................11

OPERATION .............................................................................................................................. 12

SPRING SETTING ..................................................................................................................................................................12

COUNTERBALANCE SPRING.....................................................................................................................................................12

GENERAL OPERATING PROCEDURE ...........................................................................................................................................12

ADJUSTMENTS .......................................................................................................................... 13

ADJUSTING MOVABLE BLADE GUIDE ........................................................................................................................................13

VISE OPERATION .................................................................................................................................................................13

ADJUSTING BLADE TENSION...................................................................................................................................................13

BLADE INSTALLATION/REPLACEMENT .......................................................................................................................................14

TEST CUTTING TO VERIFY ADJUSTMENT.....................................................................................................................................14

ADJUSTING BLADE SQUARE TO TABLE ......................................................................................................................................15

ADJUSTING BLADE SQUARE TO VISE ........................................................................................................................................15

SQUARING BLADE TO VISE......................................................................................................................................................15

ADJUSTING BLADE TRACKING .................................................................................................................................................16

ADJUSTING BOW ANGLE FOR MITER CUTS.................................................................................................................................16

ADJUSTING BLADE GUIDE BEARINGS........................................................................................................................................17

SELECTING THE BLADE ..........................................................................................................................................................17

BLADE SPEEDS........................................................................................................................... 18

EVALUATING CUTTING EFFICIENCY ............................................................................................ 18

MAINTENANCE ......................................................................................................................... 19

LUBRICATION............................................................................................................................ 19

TROUBLESHOOTING.................................................................................................................. 20

REPLACEMENT PARTS ............................................................................................................... 22

SAW TABLE ASSEMBLY DRAWING (1 OF 3) -EXPLODED VIEW ......................................................................................................22

SAW BOW ASSEMBLY DRAWING (2 OF 3) -EXPLODED VIEW........................................................................................................23

SAW STAND ASSEMBLY DRAWING (3 OF 3) -EXPLODED VIEW .....................................................................................................24

MBS-708CSB PART LIST .....................................................................................................................................................25

WIRING DIAGRAMS................................................................................................................... 30

MBS-708CSB ELECTRICAL APPLIANCE DESCRIPTION .................................................................................................................31