5 General Section

Section 1: Using this manual

This Manual is divided into three specific sections:

Airplane, Sailplane and Helicopter.

In this manual you will find the specifications for the

radio and its various components and accessories. In

addition, guidelines for the installation have been

included. Instructions for setting all the functions and

programs are presented in the three sections of the

manual: Airplane, Sailplane and Helicopter. These

features are discussed in the same order that they

would normally be needed to set up a typical aircraft,

servo winged sailplane and helicopter respectively. An

explanation of the use and purpose of each feature is

provided, followed by a labeled illustration of its

respective LCD display.

A blank data sheet has been included at the end of

each section. Once all data has been input for a

particular model, it is highly recommended that you

record it on a copy of the sheet provided.

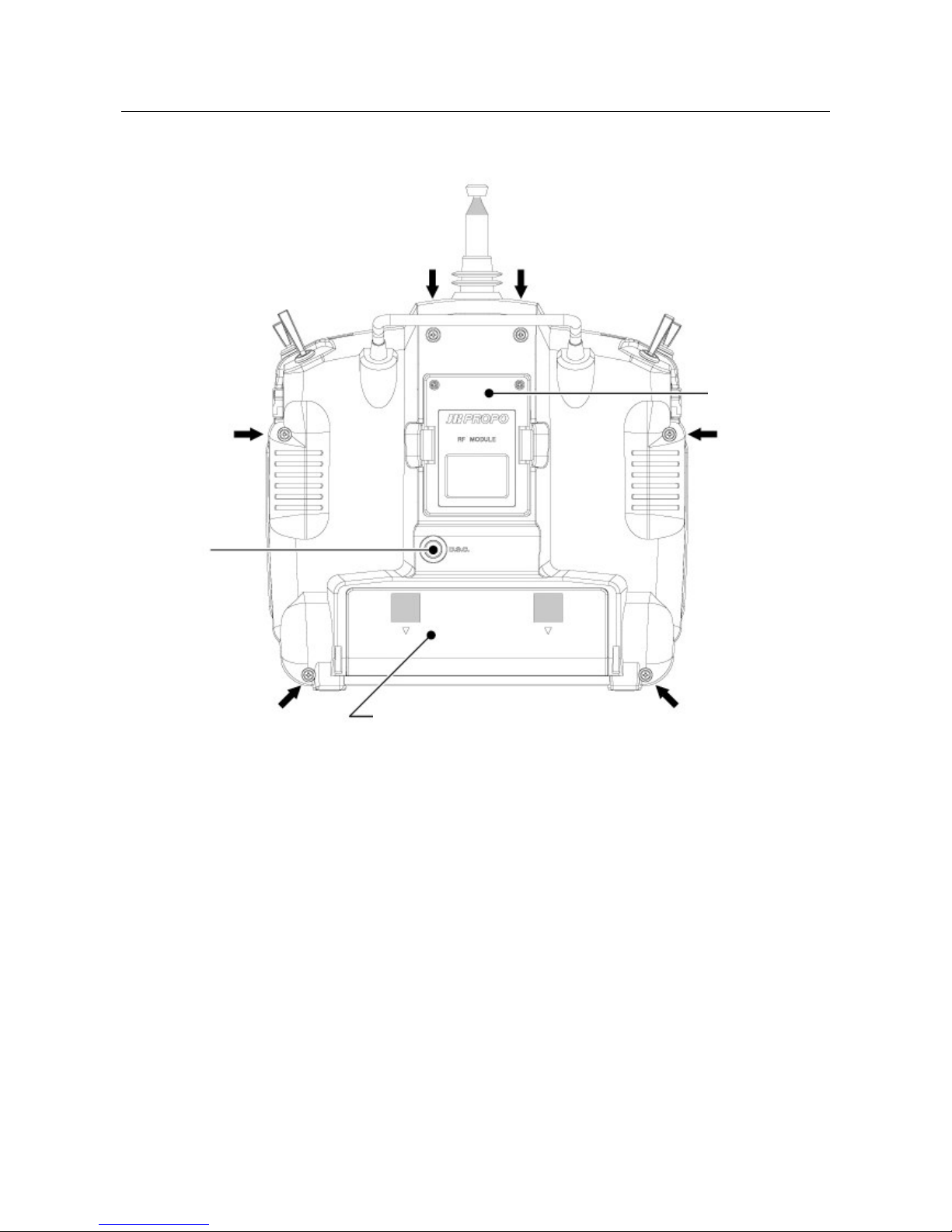

Section 2: Features

The computer-designed, ergonomically-styled

transmitter case ensures a comfortable fit in your

hands. You will also be introduced to our exclusive

“Rolling Selector” on the face of the transmitter for fast

and effortless movement through any programming

sequence.

The ultra-precision control sticks offer adjustable spring

tensions and length. The throttle stick offers a ratchet in

Airplane/Sailplane configuration. Stick modes 1-4 are

menu selectable.

30-model memory storage allows programming of all

parameters of thirty separate airplanes, sailplanes or

helicopters; you can program more than one setup for a

single aircraft, allowing you to instantly change the flight

characteristics.

R770 Receiver

R770 ( asic Air and Sailplane

Systems)

The R770 is a high-performance 7 channel PCM single-

conversion receiver with 10KHz super narrow band

ABC&W circuitry.

A narrow band ceramic filter for high-signal selectivity

assists in rejecting cross modulations from other

common radio frequencies, such as RC transmitters or

local paging systems.

This receiver features Direct Servo Control (DSC) for

control of servos without radio frequency output.

The receiver has low current consumption.

The R770’s Slimline design allows it to fit into most

model applications.

R900 Receiver

R900 (Advanced Air, asic & Advanced

Helicopter Systems)

The R900 is a high-performance 9 channel PCM single-

conversion receiver with 10KHz super narrow band

ABC&W circuitry.

A narrow band ceramic filter for high-signal selectivity

assists in rejecting cross modulations from other

common radio frequencies, such as RC transmitters or

local paging systems.

This receiver features Direct Servo Control (DSC) for

control of servos without radio frequency output.

The receiver has low current consumption.

The R900’s credit card size design allows it to fit into

most model applications.