JST CMKS-L INDUSTRY STANDARD APPLICATOR

H:\0 - Quality Documents\2 Department\Tech Serv\Application tooling\Applicators and Die sets\TS174-00

CMKS-L Manual.doc

1. APPLICATOR RAM SLIDE

1-1 SLIDE ASSEMBLY

The conductor dial (108) and the insulation dial (111) are fixed by the shank (112).

To remove the two disks you must first loosen the 4mm grub screw positioned in the

main body of the slide, now by loosening the shank you can remove both wire disks.

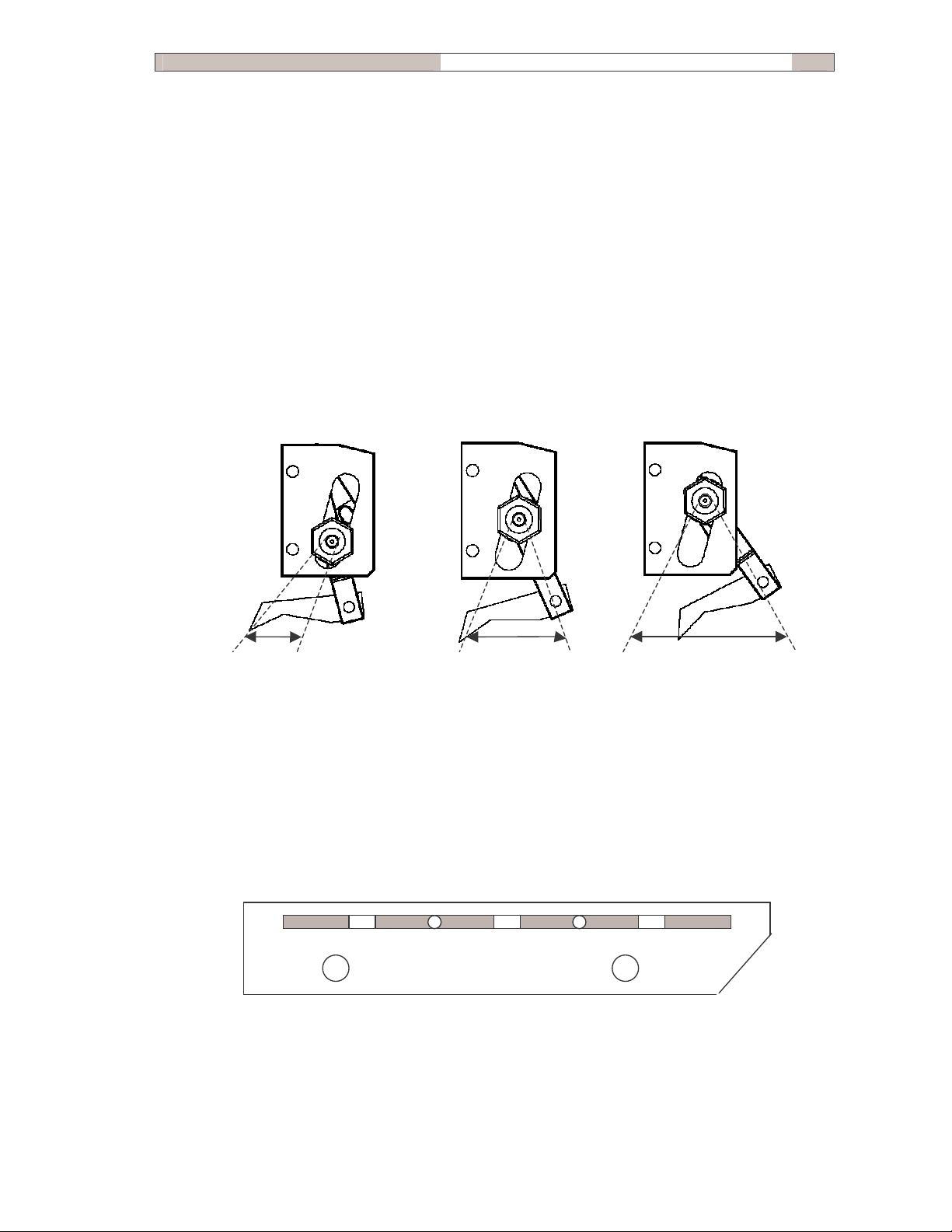

Positioned in the rear of the slide is the cam (119). There are two different cams

available for this applicator. The first type is an pre-feed cam, with this cam fitted

the terminal is present over the anvil when the press is at top dead centre, this type of

cam is commonly used when the applicator is located in a bench press. The other

type is a post-feed cam, this operates in the opposite manner, which means the

terminal feeds forward as the press travels to bottom dead centre, this type of cam is

commonly used when the applicator is located in a fully automatic machine.

1-2 TROUBLE SHOOTING

The dials are difficult to turn

1. Dismantle slide assembly as described above and check for any foreign bodies.

2. Ensure 3mm grub screw located in the insulation dial is not excessively

tightened.

3.

Check condition of the positioning Pin (109).

The dials turn freely but do not locate in position correctly

1. Check the condition of the positioning spring (110) and the positioning pin

(109). The Spring may be broken.

2.

Ensure 3mm-grub screw located in the insulation dial is adjusted correctly.

2. EJECTOR

2.1 PURPOSE

After the terminal has been successfully crimped on the wire, the terminal may

adhere to the punches; the ejector assures the function of stripping the terminal

from the punches.

2.2 ASSEMBLY

Place the ejector punch with relevant spring (159) into the corresponding slot of

ejector holder (160) ensuring the ejector slides freely up and down when fixed into

position on the front of the crimping punches.