Purl stitching ←→ Whip stitching Single stitching ←→ Double stitching

●The basting stitch is effective on elastic materials such as knits.

Basting stitch: Since the needle thread is tucked in without fail,

it will never jut out of the buttonhole seams.

Basting stitch can be sewn by nine rounds.

●

(The state in which the material is stretched in

the lengthwise direction after buttonholing)

①Maximum position

Cloth

②Intermediate position

③Sewing position

(For a changeover between purl stitch

and whip stitch, threading of bobbin,

as well as the bobbin thread tension

need to be changed.)

•For double stitching, the bartacking

section is skipped and only the parallel

sections are sewn twice. This prevents

any excessively tight finishes in the

bartacking section of the buttonhole.

•First- and second-round stitches can be

sewn using different stitch widths.

17mm17mm

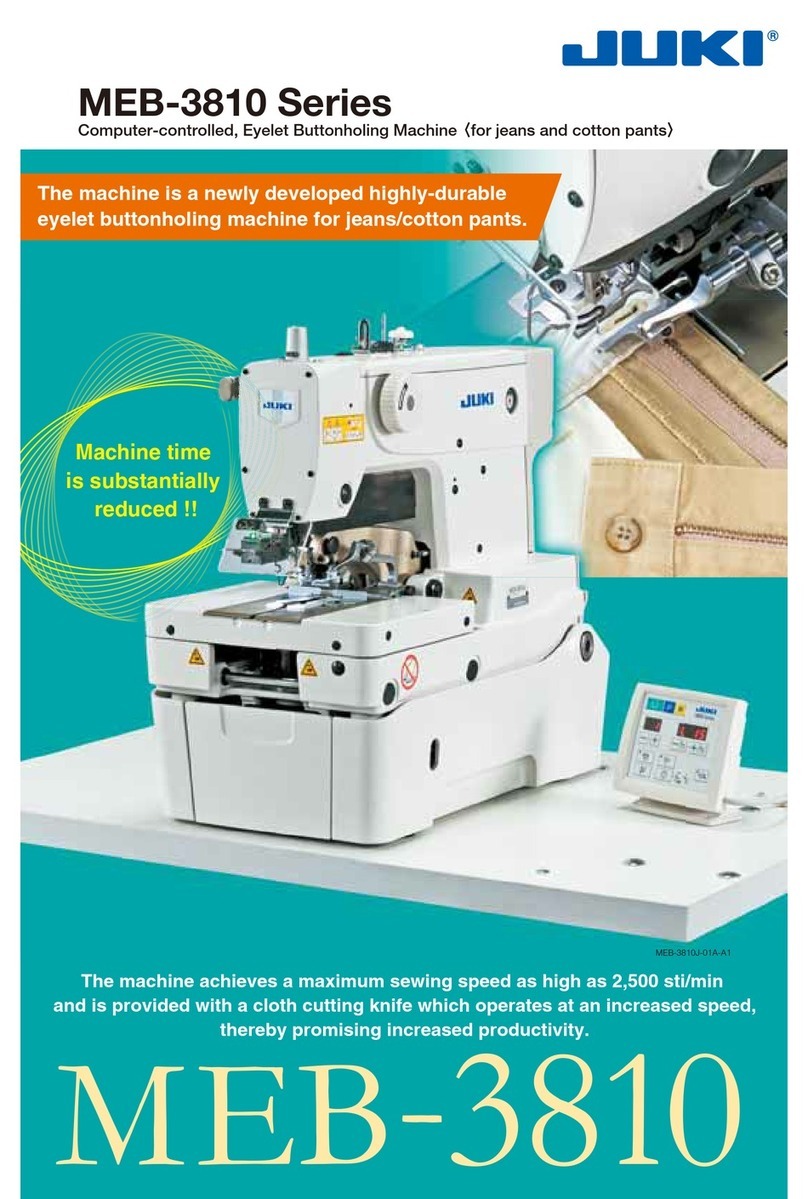

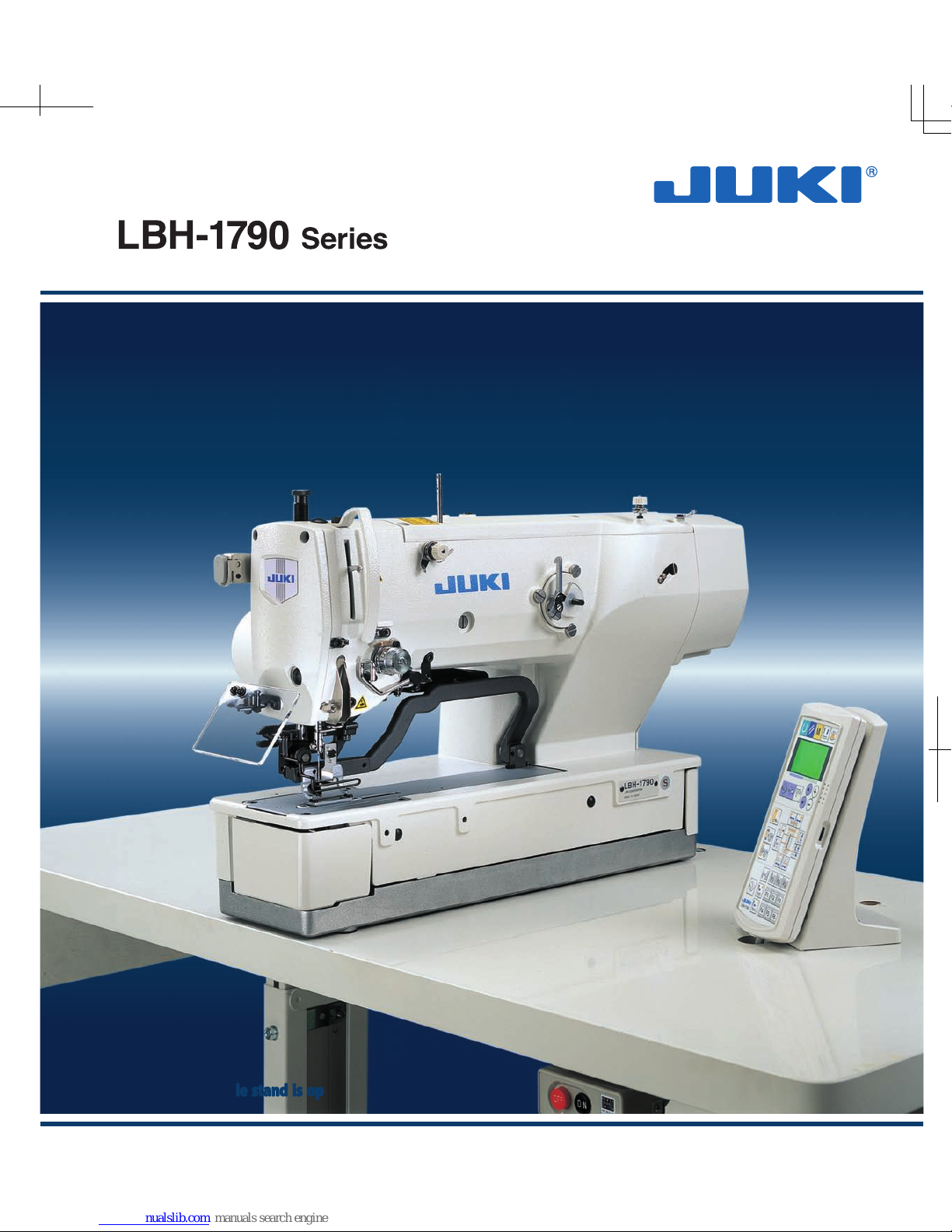

Compact AC servomotor

(direct-drive) Stepping motor

for the presser bar lifter Stepping motor for the bobbin thread trimmer

Stepping motor for the cloth feed

Stepping motor for the bobbin thread trimmer

Stepping motor for the cloth feed

Stepping motor

for the needle throw

Stepping motor

for the needle thread trimmer

Double acting solenoid

for the cloth cutting knife

Compact AC servomotor

(direct-drive) Stepping motor

for the presser bar lifter

Stepping motor

for the needle throw

Stepping motor

for the needle thread trimmer

Double acting solenoid

for the cloth cutting knife

●Thanks to the multiple knife-dropping function, it is no longer required

that the knife be changed at the time the buttonhole size is changed.

The number of knife dropping times can be automatically set according

to the buttonholing size in cases where the buttonhole size is frequently

changed for small-lot productions or during the cycle sewing of

buttonholes that are different in size.

●The double-acting solenoid type knife mechanism is free from the faulty

dropping/returning of the knife. In addition, the knife pressure can be

changed according to the material to be sewn.

●The knife supports sewing lengths of 41mm at the maximum. In addition,

knife mechanisms for 70mm and 120mm are optionally available.

Since the LBH-1795 is provided as standard with the 120 mm presser, it

is capable of sewing 12-mm long buttonholes. The LBH-1795 is capable

of sewing long buttonholes such as belt holes in car seats. In addition, it

is applicable to the sewing of buttonholes in men's shirts (continuous

sewing of two buttonholes and the use of two units of sewing machines),

etc.

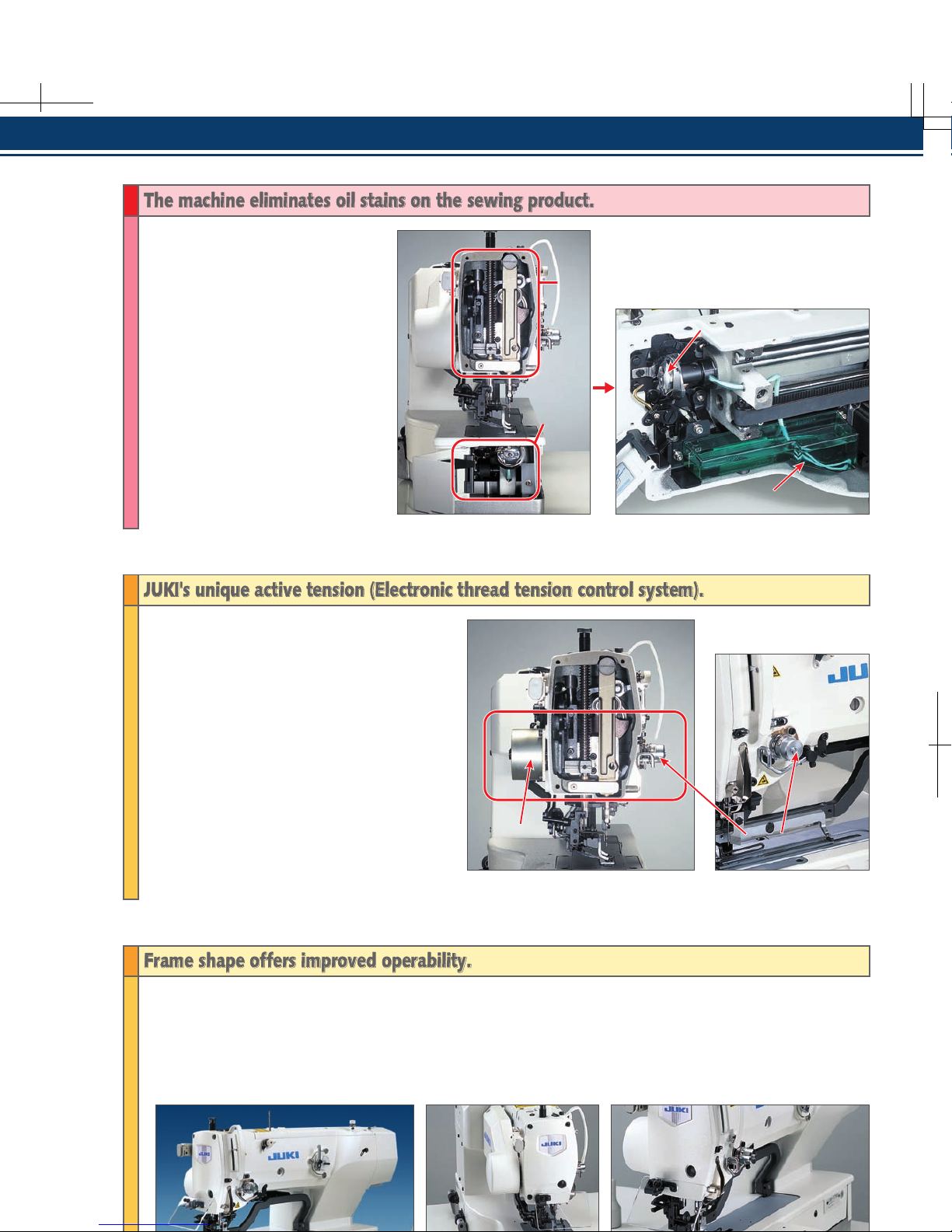

●The new model of the bobbin thread trimming

mechanism cuts the bobbin thread so that it leaves

a shorter length of thread on the material.

Furthermore, the machine produces bartacks at the

end of sewing, thereby preventing finished seams

from coming undone.

●With the soft-start function, the number of stitches,

as well as the sewing speed at the start of sewing

can be specified, thereby preventing the needle

thread from slipping off from the needle eyelet.

(From the first to the fifth stitches, the sewing speed

can be specified on a stitch-by-stitch basis.)

!

●An electronic control feature has been adopted for the material feed

mechanism, needle rocking mechanism, needle thread trimming mechanism,

bobbin thread trimming mechanism, cloth cutting knife mechanism and presser

bar lifting mechanism. In addition, mechanisms such as V-belts, stop-motion

mechanisms and cams have been substantially reduced to ensure operation

with lower vibration and noise.

●A direct-driven system that directly connects the

compact AC servomotor to the main shaft has been

adopted.

●All adjustment values are entered as data. They can be

set or stored in the memory on the operation panel.

"

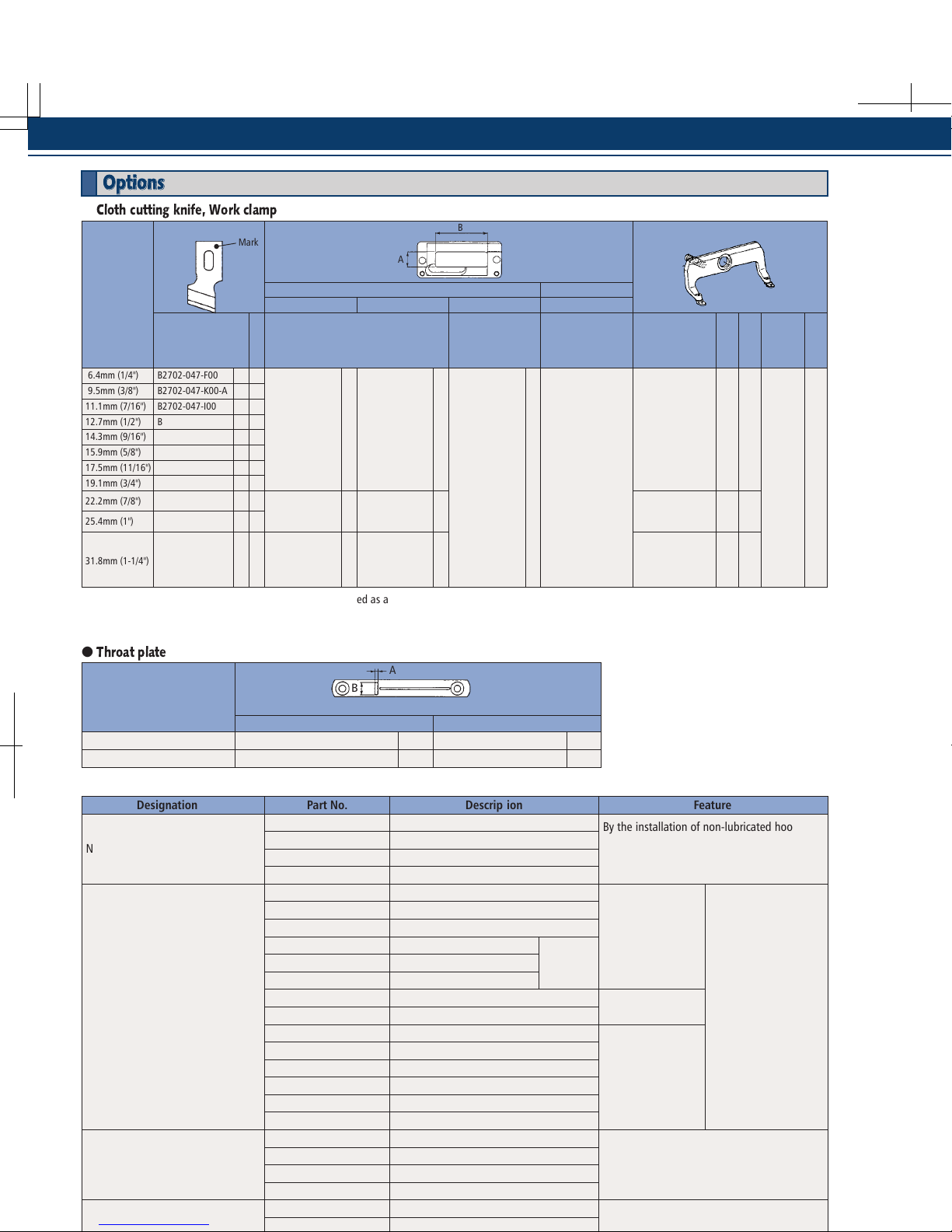

●The machine is provided as standard with a newly-developed auto-lifter driven

by a stepping motor. This helps reduce the operator's fatigue. This helps reduce

operator fatigue. As for the pedal, one-pedal and two-pedal models can both be

changed over and the intermediate stop, which facilitates positioning of the

sewing product, can be specified.

●The work clamp foot lift can be set as desired.

The reverse-rotation needle-up function offers

a maximum work clamp foot lift of 17mm.

!

Cycle sewing

●Twenty different programs can be registered, and as many

as 15 different patterns can be stored in one program.

Continuous sewing

●The machine is able to continuously sew two or more

different patterns without requiring the work clamp foot to

be lifted. As may as 20 programs can be registered, and

six different patterns can be stored in one program.

(Related parts need to be exchanged for optional ones.)

#!

●The needle bar can be shifted to the rightmost end

position with the work clamp foot lowered.

This facilitates threading of the machine head.

!

!

Pedal motion

Pedal type

2-pedal 1-pedal 1-pedal

(without intermediate position) (with intermediate position)

Initial position

Setting of sewing product

Start of sewing

End of sewing

Finished state of

double stitching

State of first-

round stitch

Whip stitchingPurl stitching

Without basting stitch With basting stitch Basting stitch

Position of the needle bar

during sewing

The needle bar can be shifted to

the right at the time of threading

②Intermediate position

Presser goes up as high as the pedal

toe down amount of the left side pedal.

Presser comes down when the left

side pedal is depressed.

→③Sewing position

The right side pedal is depressed.

②Presser automatically goes up to

intermediate position.

①Maximum position

The first step of the right side pedal

→③Sewing position

The second step of the right side pedal

①Presser automatically goes up to

maximum position.

①Maximum position

The first step of the right side pedal

→②Intermediate position

↓

The second step of the right side pedal

→③Sewing position

The third step of the right side pedal

①Presser automatically goes up to

maximum position.

120mm buttonhole

LBH-1795S