i

CONTENTS

!.

IMPORTANT SAFETY INSTRUCTIONS........................................................................1

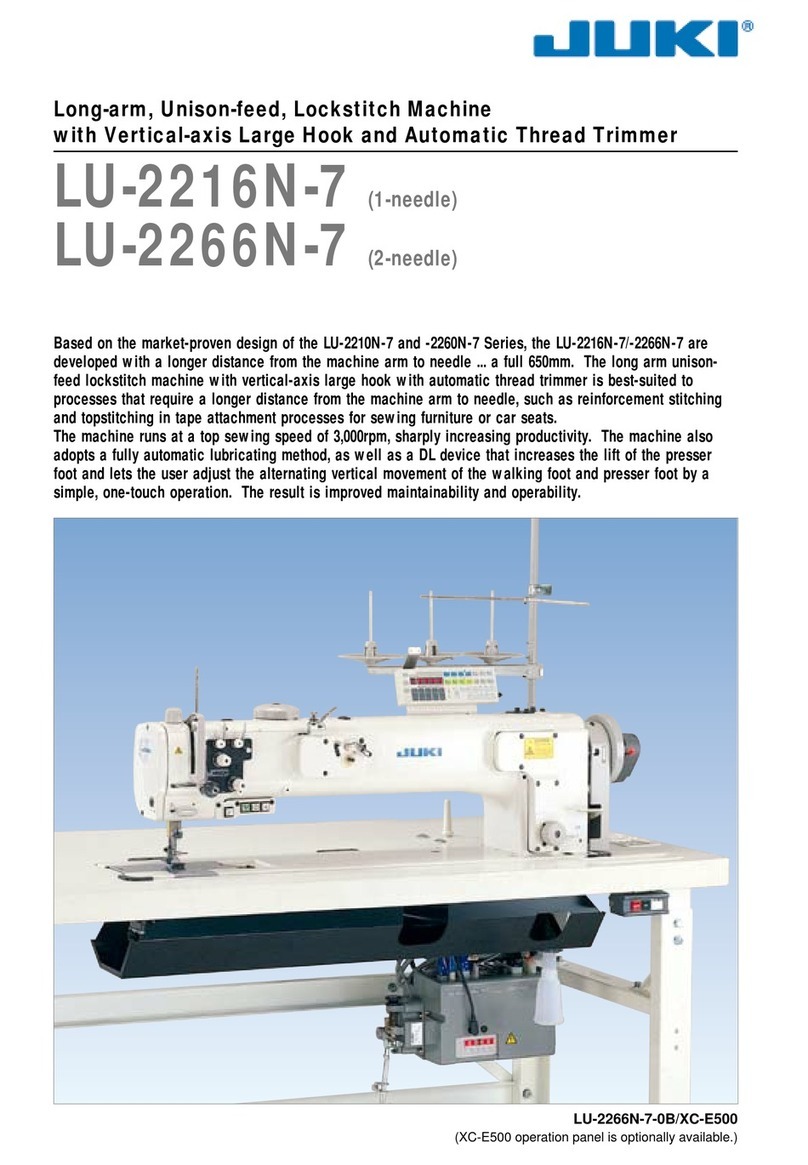

@.SPECIFICATIONS..........................................................................................................1

1. Subclass................................................................................................................................................1

2.Specications .......................................................................................................................................1

3.Standardsewingshapelist .................................................................................................................2

4.Conguration ........................................................................................................................................3

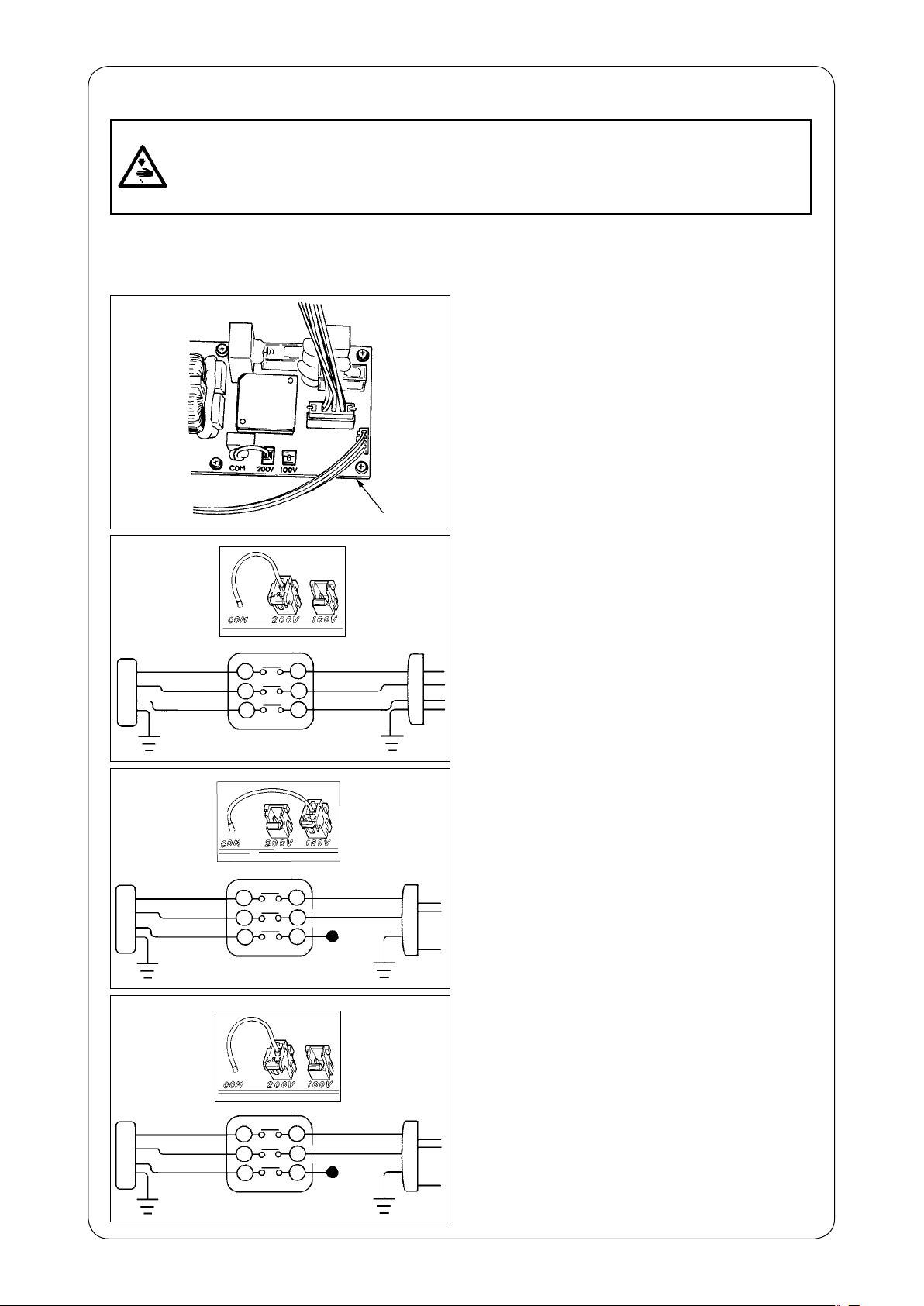

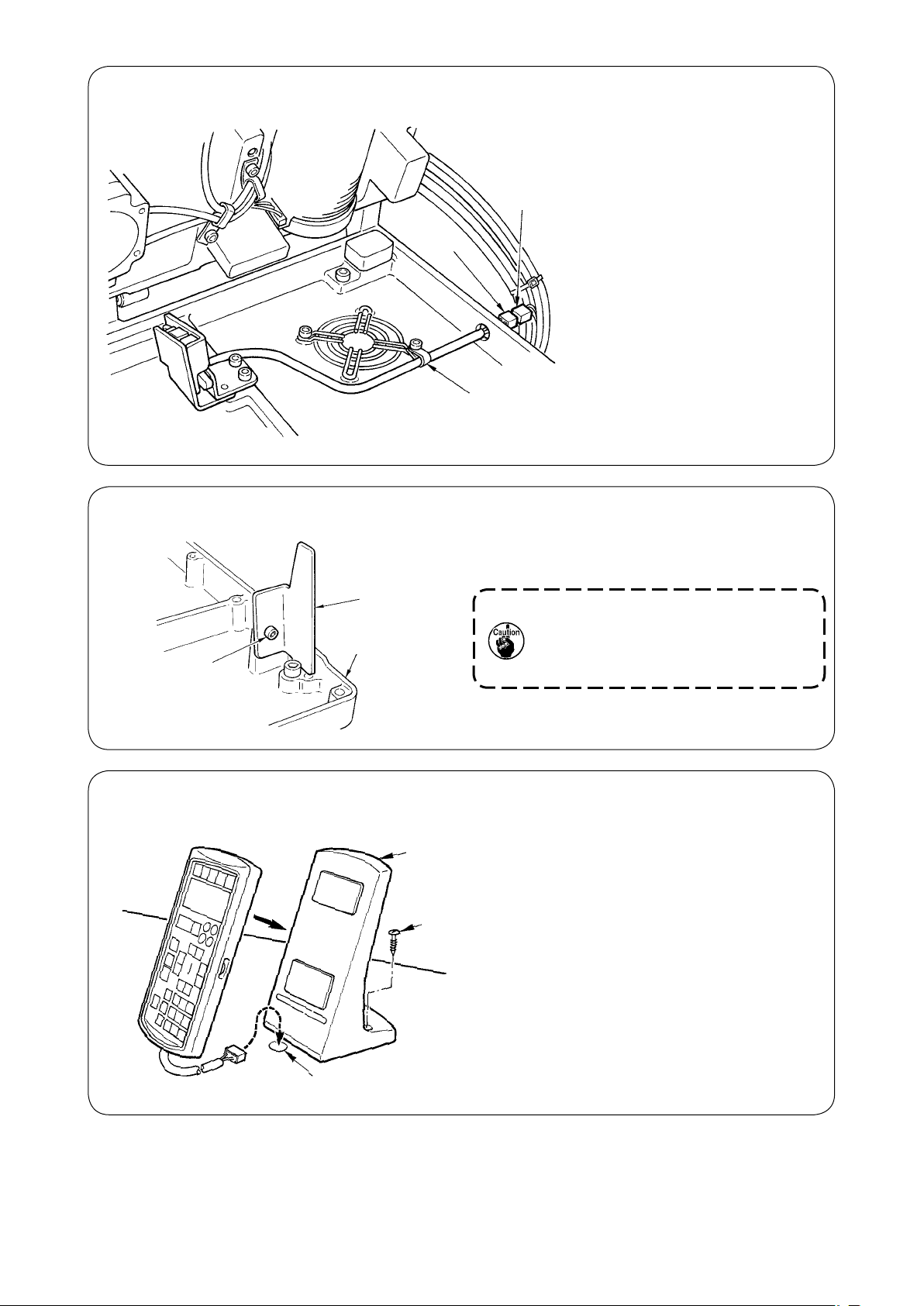

#. INSTALLATION ..............................................................................................................4

$. PREPARATION BEFORE OPERATION ......................................................................12

1.Lubrioation ..........................................................................................................................................12

2.Insertingtheneedle............................................................................................................................12

3.Threadingtheneedle-thread .............................................................................................................13

4.Threadingthebobbincase ................................................................................................................13

5.Adjustingthebobbinthreadtension ................................................................................................14

6.Installationofbobbincase ................................................................................................................14

7.Installingtheknife ..............................................................................................................................15

%. OPERATION OF THE SEWING MACHINE .................................................................16

1.Explanationoftheoperationpanelswitch.......................................................................................16

2.Basicoperationofthesewingmachine ...........................................................................................18

3.Howtousethepedal..........................................................................................................................18

4.Inputofthepressertype....................................................................................................................20

5.Performingpatternselection.............................................................................................................21

6.Changingneedlethreadtension .......................................................................................................22

7.Performingre-sewing.........................................................................................................................23

8.Windingbobbinthread.......................................................................................................................24

9.Usingthecounter ...............................................................................................................................25

10.Usingtheinitialvaluepattern............................................................................................................26

11.Changingsewingdata........................................................................................................................27

12.Methodofsettingsewingdatawith/withoutedit.............................................................................28

13.Sewingdatalist...................................................................................................................................29

14.Copyingsewingpattern .....................................................................................................................34

15.Usingpatternregisterkey .................................................................................................................35

16.Usingparameterregisterkey ............................................................................................................36

17.Performingcontinuousstitching ......................................................................................................37

18.Performingcyclestitching.................................................................................................................39

19.Explanationofpluralmotionsofknife .............................................................................................41

20.Methodofchangingmemoryswitchdata ........................................................................................42

21.Memoryswitchdatalist .....................................................................................................................43

^. MAINTENANCE ...........................................................................................................47

1.Adjustingtheneedle-to-hookrelation ..............................................................................................47

2.Adjustingtheneedlethreadtrimmer ................................................................................................48

3.Adjustingthepresserbarpressure ..................................................................................................49

4.Adjustmentofthebobbinpresserunit.............................................................................................49

5.Threadtension ....................................................................................................................................50

6.Cleaningthelter ...............................................................................................................................51

7.Replacingthefuse..............................................................................................................................51

&. GAUGE COMPONENTS..............................................................................................52

1.Clothcuttingknife ..............................................................................................................................52

2.Throatplate .........................................................................................................................................52

3.Presser.................................................................................................................................................52

*. ERROR CODE LIST.....................................................................................................53

(. TROUBLES AND CORRECTIVE MEASURES ...........................................................56

). DRAWING OF THE TABLE..........................................................................................58

_. INITIAL VALUE DATA FOR EACH SHAPE TABLE ....................................................59