vii

CONTENTS

I. IMPORTANT SAFETY INSTRUCTIONS ..................................................... 1

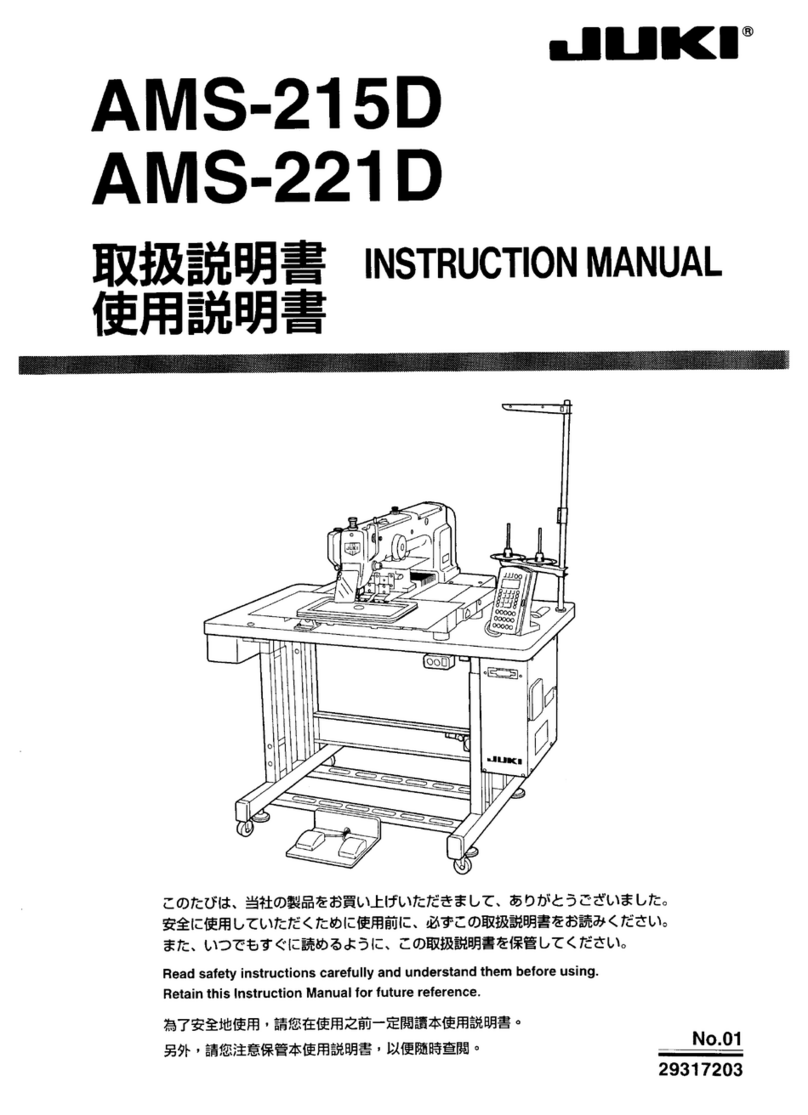

II. SPECIFICATIONS....................................................................................... 1

1.Specications.......................................................................................................................1

2. Standard sewing shape list.................................................................................................2

3.Conguration .......................................................................................................................3

III. INSTALLATION.......................................................................................... 4

IV.PREPARATIONBEFOREOPERATION.................................................. 14

1. Lubrication .........................................................................................................................14

2. Inserting the needle ...........................................................................................................14

3. Threading the needle-thread.............................................................................................15

4. Threading the bobbin case ...............................................................................................15

5. Adjusting the bobbin thread tension ...............................................................................16

6. Installation of bobbin case................................................................................................16

7. Installing the knife .............................................................................................................17

8. Checking the sewing machine in the delivered state.....................................................17

V.OPERATIONOFTHESEWINGMACHINE.............................................. 18

1. Explanation of the operation panel switch......................................................................18

2. Basic operation of the sewing machine ..........................................................................20

3. How to use the pedal .........................................................................................................21

4. Input of the presser type ...................................................................................................23

5. Performing pattern selection ............................................................................................24

6. Changing needle thread tension ......................................................................................25

7. Performing re-sewing ........................................................................................................26

8. Winding bobbin thread......................................................................................................27

9. Using the counter ..............................................................................................................28

10. Using the initial value pattern...........................................................................................30

11. Changing sewing data .......................................................................................................31

12. Method of setting sewing data with/without edit ............................................................32

13. Sewing data list..................................................................................................................33

14. Copying sewing pattern ....................................................................................................39

15. How to edit/check the data other than sewing data .......................................................40

16. Using parameter register key ...........................................................................................42

17. Performing continuous stitching .....................................................................................43

18. Performing cycle stitching................................................................................................46

19. How to change the name of cycle/continuous sewing data ..........................................49

20. Explanation of plural motions of knife.............................................................................50

21. Method of changing memory switch data .......................................................................51

22. Memory switch data list ....................................................................................................52

23. How to adjust the pedal variable resistor........................................................................56