CONTENTS

1. GENERAL...................................................................................................1

(1) Features................................................................................................................... 1

(2) Configuration of the main parts ............................................................................ 2

2. SPECIFICATIONS ......................................................................................3

3. ADJUSTMENT OF EACH MAIN COMPONENT........................................4

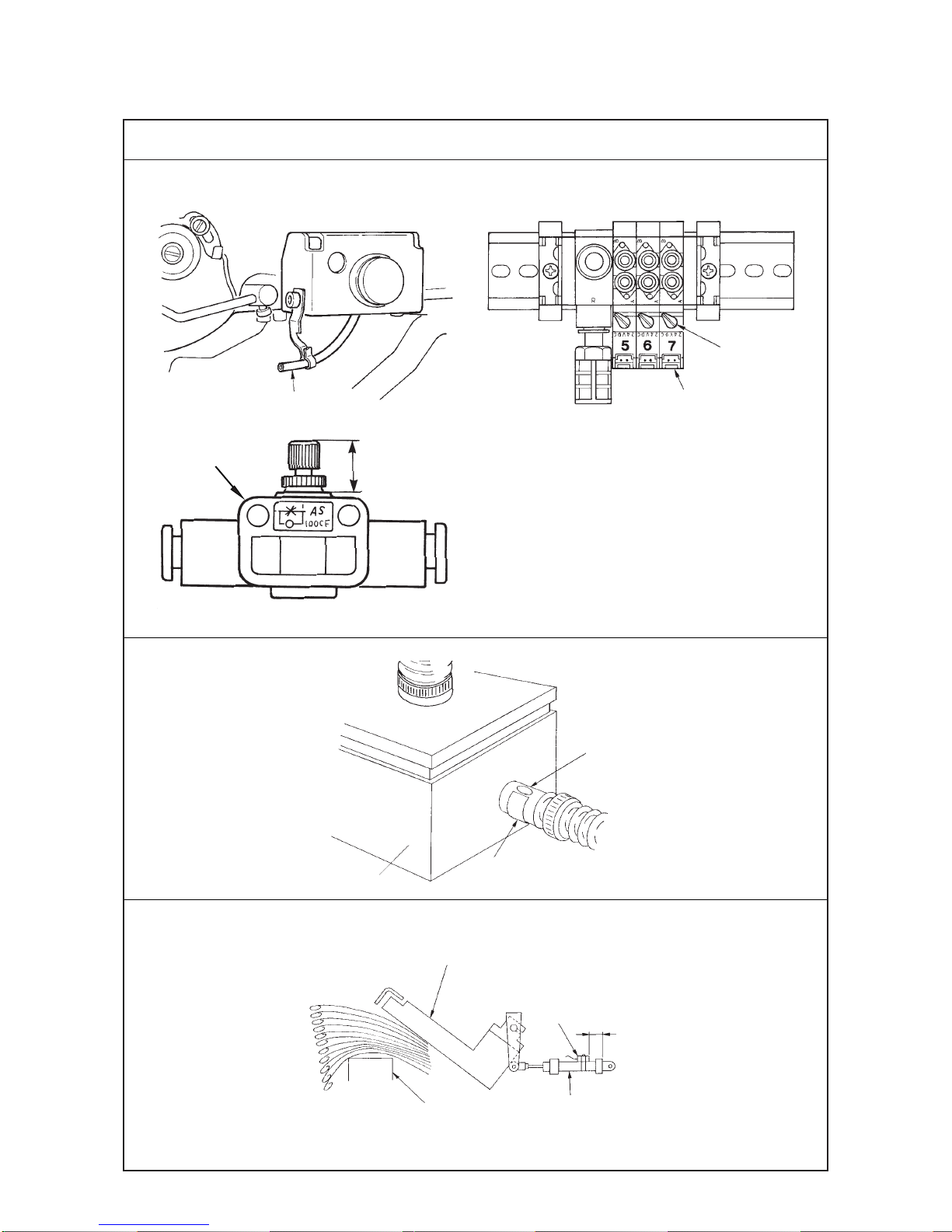

(1) Adjustment of the pneumatic components.......................................................... 4

1) Adjusting the air blower..................................................................................................................4

2) Adjusting the air blower for the needle bar.....................................................................................6

3) Vacuum adjusting metal fittings......................................................................................................6

4) Sensor to detect the number of garment bodies stacked...............................................................6

(2) Adjusting the carriage lamp .................................................................................. 8

1) Adjusting the position of the clamps...............................................................................................8

2) Adjusting the clamping force..........................................................................................................8

(3) Adjusting the stacking board of the stacker......................................................10

4. ERROR CODE LIST .................................................................................12

5. OPERATION FLOW CHART....................................................................16

6. STANDARD ADJUSTMENT....................................................................26

(1) Carriage components...........................................................................................26

1) Carriage drive components..........................................................................................................26

2) Carriage origin position components............................................................................................28

3) Carriage clamp table components...............................................................................................

4) Carriage clamp components (Including the blower).....................................................................32

.30

(2) Preset components .............................................................................................. 34

1) Configuration................................................................................................................................34

2) Preset slide components (including installing the preset table)....................................................36

3) Preset stopper components..........................................................................................................38

4) Preset drive components..............................................................................................................40

5) Set plate components...................................................................................................................42

6) Preset components and others.....................................................................................................42

(3) Stacker components ............................................................................................ 44

1) Configuration ................................................................................................................................ 44

2) Motion order ................................................................................................................................. 45

3) Swing bar components ................................................................................................................. 46

4) Cloth piling table components ...................................................................................................... 48

5) Pusher rocking components ......................................................................................................... 48

6) Cylinder tilt components ............................................................................................................... 50

7) Pusher drive components............................................................................................................. 50

8) Stacker components and others................................................................................................... 52

7. PANEL......................................................................................................54

(1) PANEL BASIC OPERATION.................................................................................54

(2) TABLE OF OPERATION BUTTON AND DISPLAY..............................................56

8. VARIOUS DATA LIST..............................................................................57

(1) Initial value data for each shape table................................................................57

(2) Sewing data list.....................................................................................................58

(3) Memory switch data list.......................................................................................64