i

CONTENTS

1. SPECIFICATIONS ........................................................................................................... 1

2. PREPARATION OF THE SEWING MACHINE ................................................................ 1

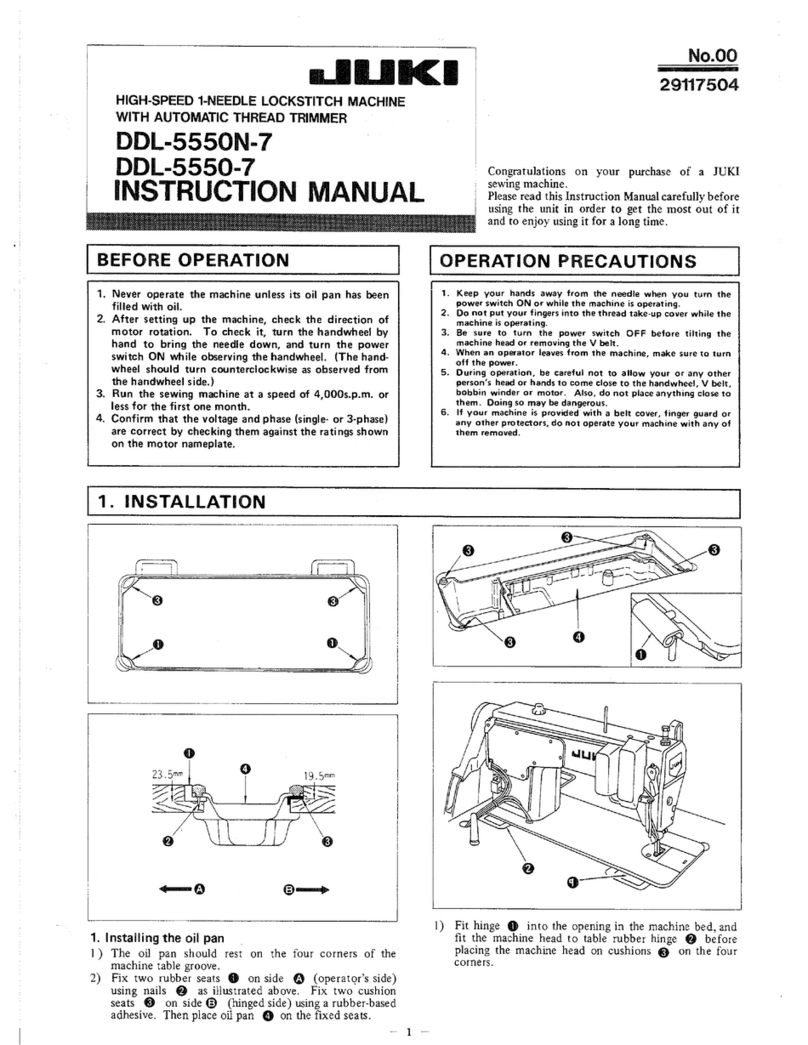

2-1. Installation ..........................................................................................................................................1

2-2. Lubrication.......................................................................................................................................... 2

2-3. Attaching the needle..........................................................................................................................2

2-4. Attaching the needle bar cover.........................................................................................................3

2-5. Attaching the button tray assembly .................................................................................................3

2-6. Threading the machine...................................................................................................................... 3

3. ADJUSTMENT OF THE SAWING MACHINE ................................................................. 4

3-1.

Thread tension adjustment........................................................................................................................ 4

3-2.

Adjustment of the thread pull-off lever .................................................................................................... 4

3-3. Adjusting the tension lever ............................................................................................................... 4

3-4. Adjusting the nipper ..........................................................................................................................5

3-5. Adjusting the thread tension guide on the face plate..................................................................... 5

3-6.

Needle-to-looper relation .................................................................................................................................... 5

3-7. Position of the needle guide ............................................................................................................. 6

3-8. Height of the button clamp................................................................................................................ 6

3-9. Work pressing force .......................................................................................................................... 6

3-10.

Adjustment of the button clamp stop lever.....................................................................................6

3-11. Timing of thread tension release ....................................................................................................7

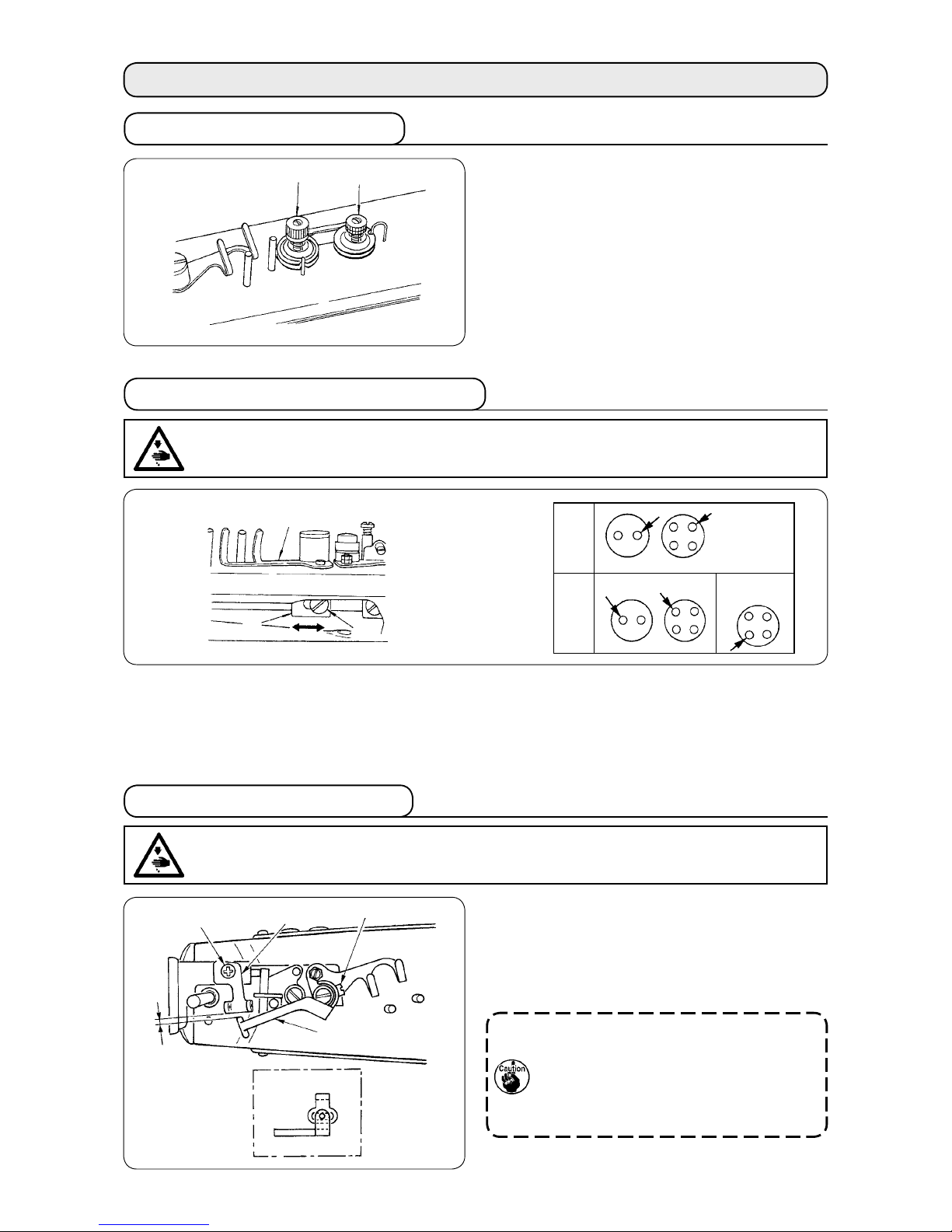

3-12. Setting for 2- or 4-hole buttons....................................................................................................... 7

3-13. Setting a number of stitches........................................................................................................... 8

3-14. Adjusting the position of the stop-motion.....................................................................................8

3-15. Automatic thread trimmer ...............................................................................................................9

(1) Adjusting the position of the moving knife......................................................................................9

3-16. Clearance between the button clamp lifting lever and the adjusting screw .............................. 9

3-17. How to set the L-shaped lifting rod ................................................................................................9

3-18. Knot-tying mechanisms ................................................................................................................10

(1) Adjusting the knot-tying connecting plate.....................................................................................10

(2) Adjusting the knot-tying arm stopper............................................................................................10

(3) Adjusting the knot-tying notch ......................................................................................................10

(4) Changeover of with/without knot-tying ......................................................................................... 11

4. MAINTENANCE, SUBCLASS MODELS AND ATTACHMENTS .................................. 11

4-1. How to connect the metal ttings of the belt ................................................................................ 11

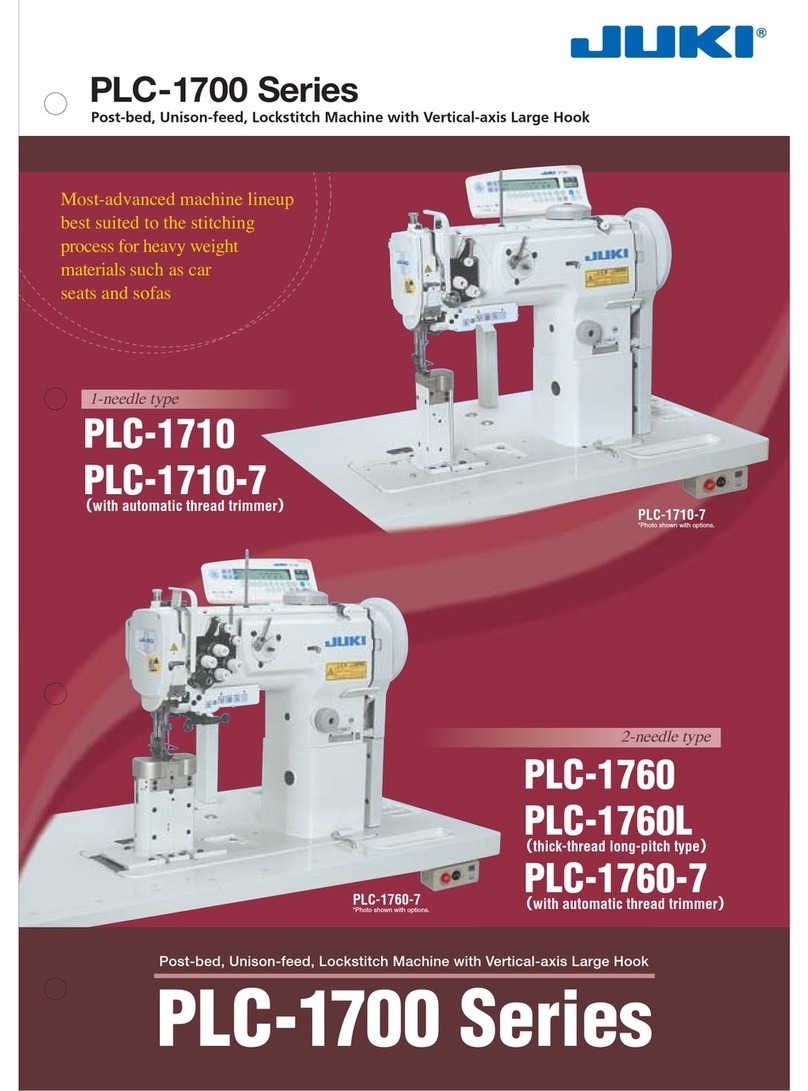

4-2. Subclass models ............................................................................................................................. 11

4-3. Attachments......................................................................................................................................12

(1) Attachments for shank buttons (Pearl buttons) (Z033) ................................................................13

(2) Attachment for the rst process of wrapped-around buttons (Z041)............................................13

(3) Attachment for the second process of wrapped-around buttons (Z035) ...................................... 14

(4) Attachment for snaps (Z037)........................................................................................................14

(5) Attachment for metal buttons (Z038)............................................................................................15

4-4. Motor pulley and belt .......................................................................................................................15

5. TROUBLES AND CORRECTIVE MEASURES ............................................................. 16