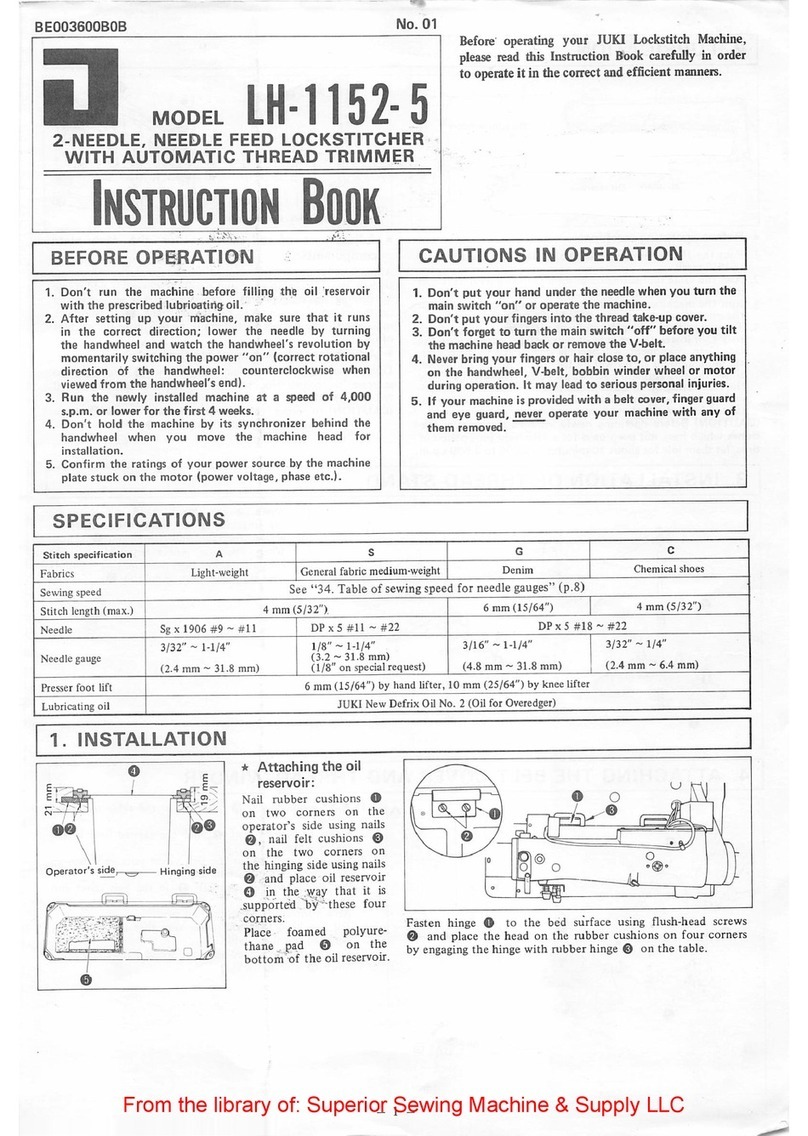

– 3 –

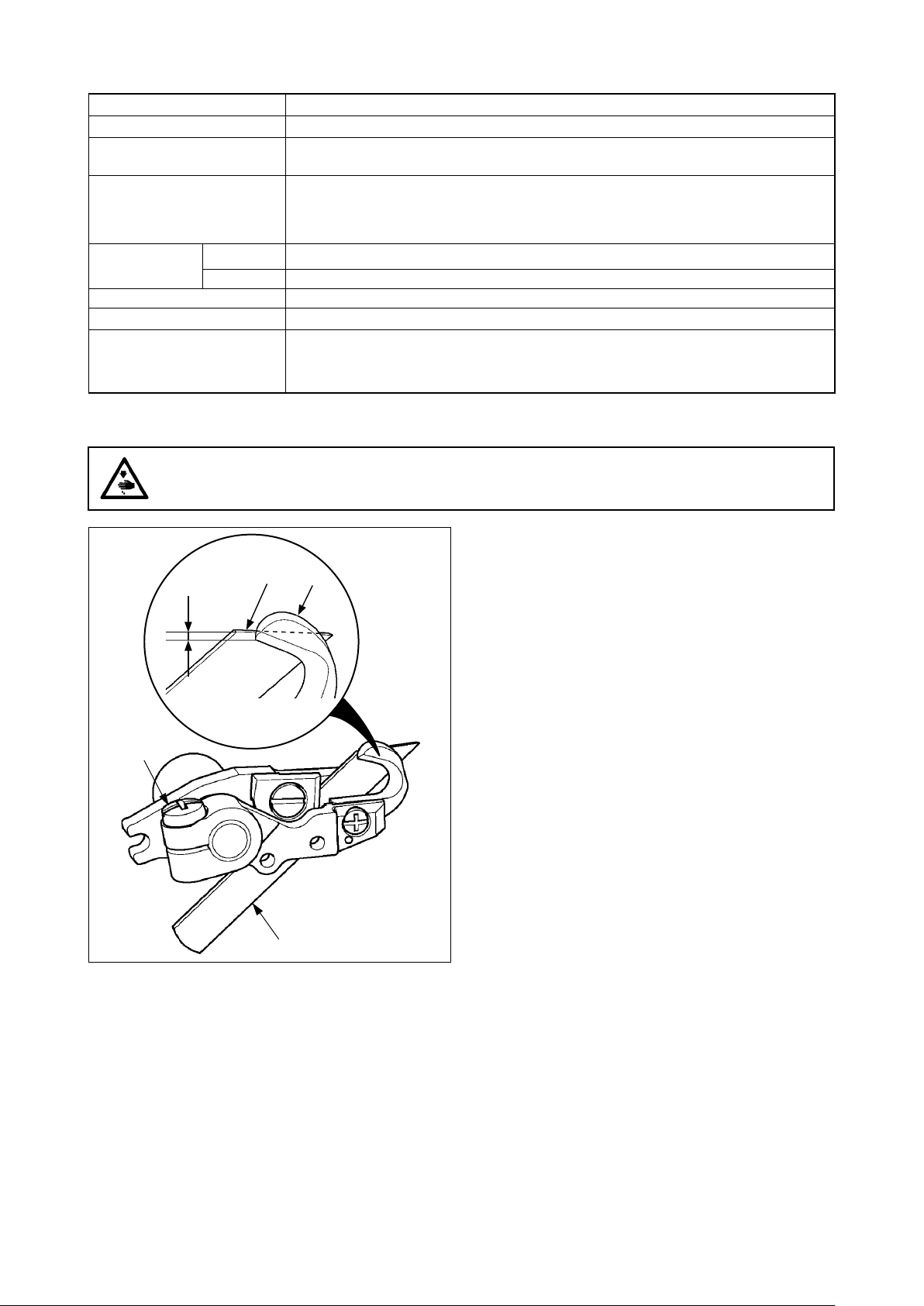

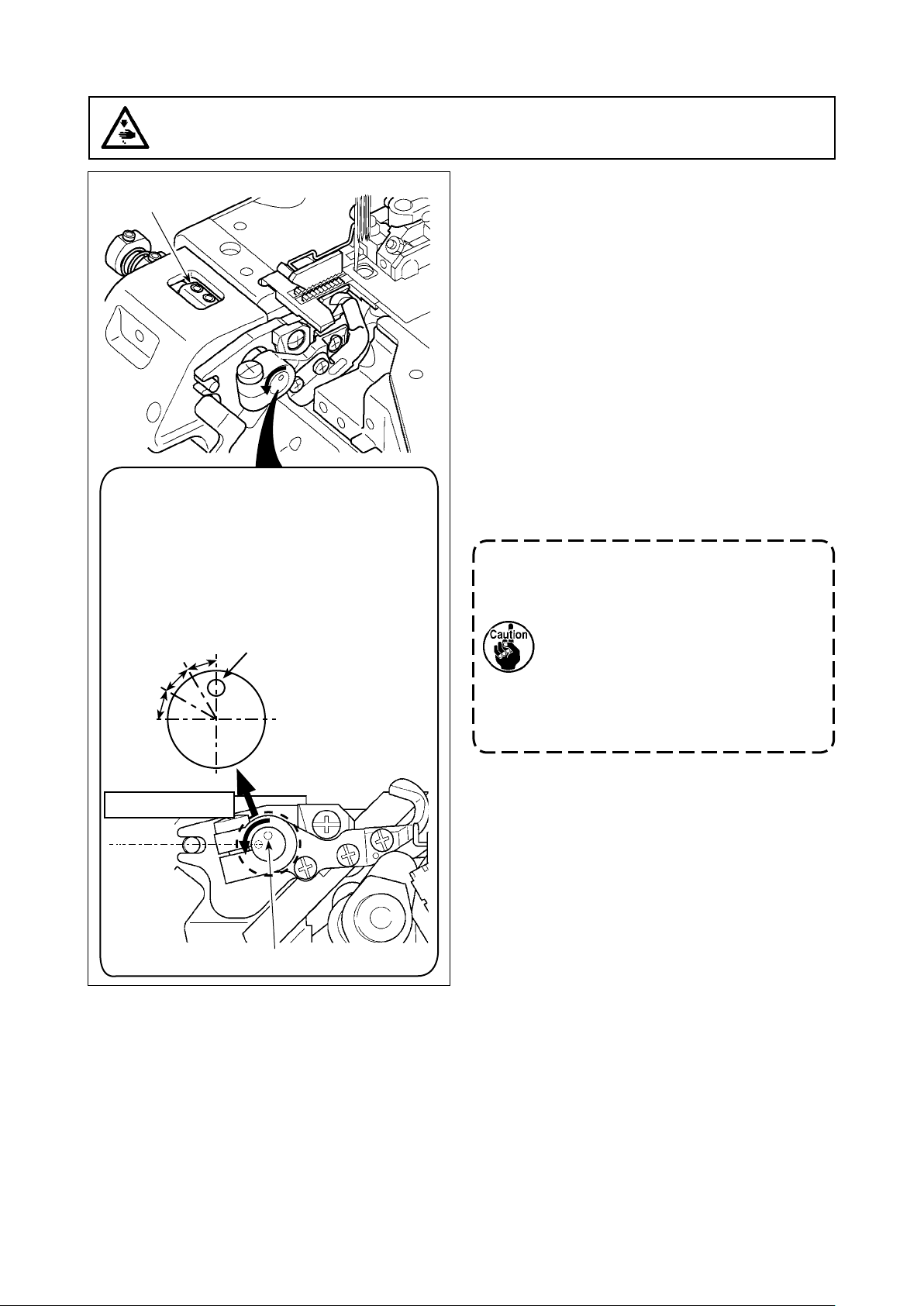

1)

Loosen setscrew ❶ of the adjusting lever. Adjust the

sharpness of the knife by turning the adjusting lever

counterclockwise according to the sharpness of the

knife.

2)

After the adjustment of the knife sharpness, tighten set-

screw ❶ of the adjusting lever.

3)

After the adjustment of the engagement, carry out "3.

ADJUSTING THE UPPER KNIFE PRESSURE" p.2

and "2. ADJUSTMENT PROCEDURE OF ENGAGE-

MENT AMOUNT OF KNIVES" p.1.

4)

In the delivered state of the sewing machine, the posi-

tion of marker dot A orients to the 12 o'clock direction,

as observed from the pulley side, when the knife is in

its lower dead point. Adjust to decrease the angle of

mesh bit by bit such as from 12 o'clock to 11 o'clock,

then to 10 o'clock.

1. The extent of the adjustment of the angle of

mesh is until marker dot A is turned coun-

terclockwise to reach the horizontal posi-

tion. If the lever is turned beyond the above,

the angle between the upper knife and the

lower knife will increase.

2. If the depth of engagement is excessively

increased, the knife can wear.

3. Adjust the knife so that it cuts well and the

depth of engagement is not excessive

Counterclockwise turn

❶

Marker dot A

B: Standard adjustment angle

C:

Angle adjusted for hard-to-sew materials

D:

Angle adjusted when the knife has worn

* If the knife engagement angle is adjusted to

D from the start, the knife can wear earlier

than the case where the angle is adjusted

the standard one.

Horizontal

position

B

C

D

Marker dot A

5. ADJUSTING THE ENGAGEMENT ANGLE OF THE KNIFE

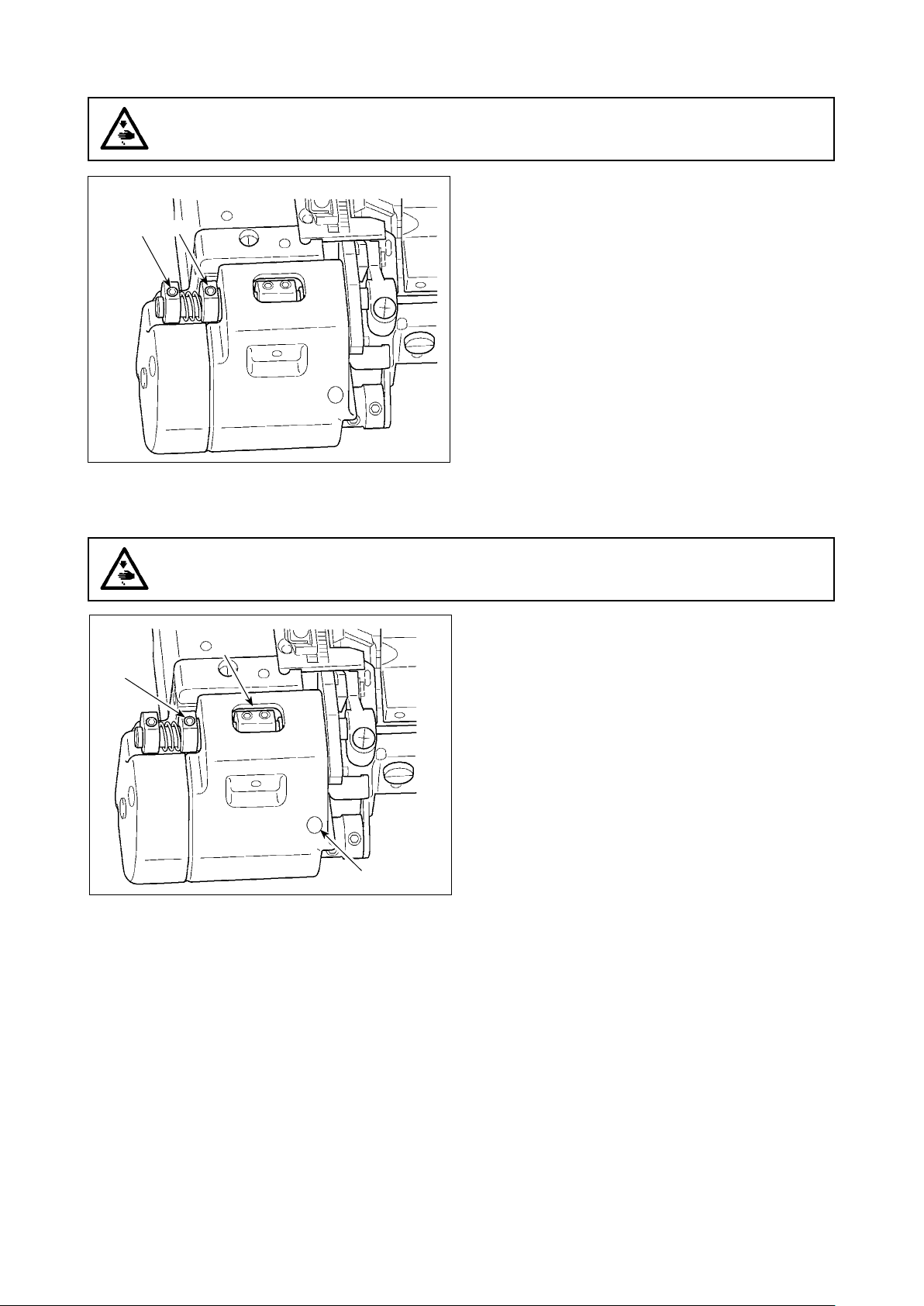

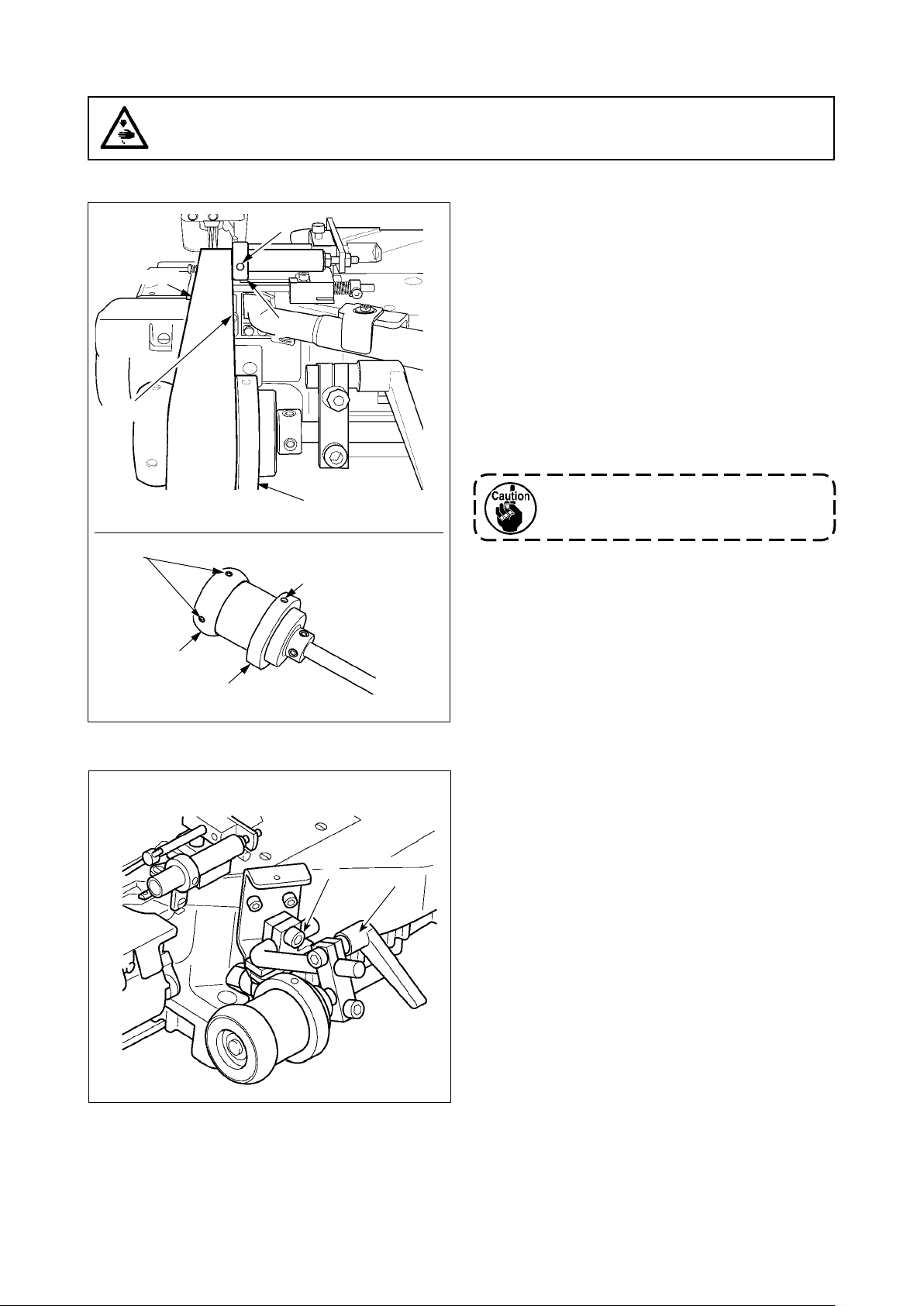

WARNING :

To protect against possible personal injury due to abrupt start of the machine, be sure to start the follow-

ing work after turning the power off and ascertaining that the motor is at rest.