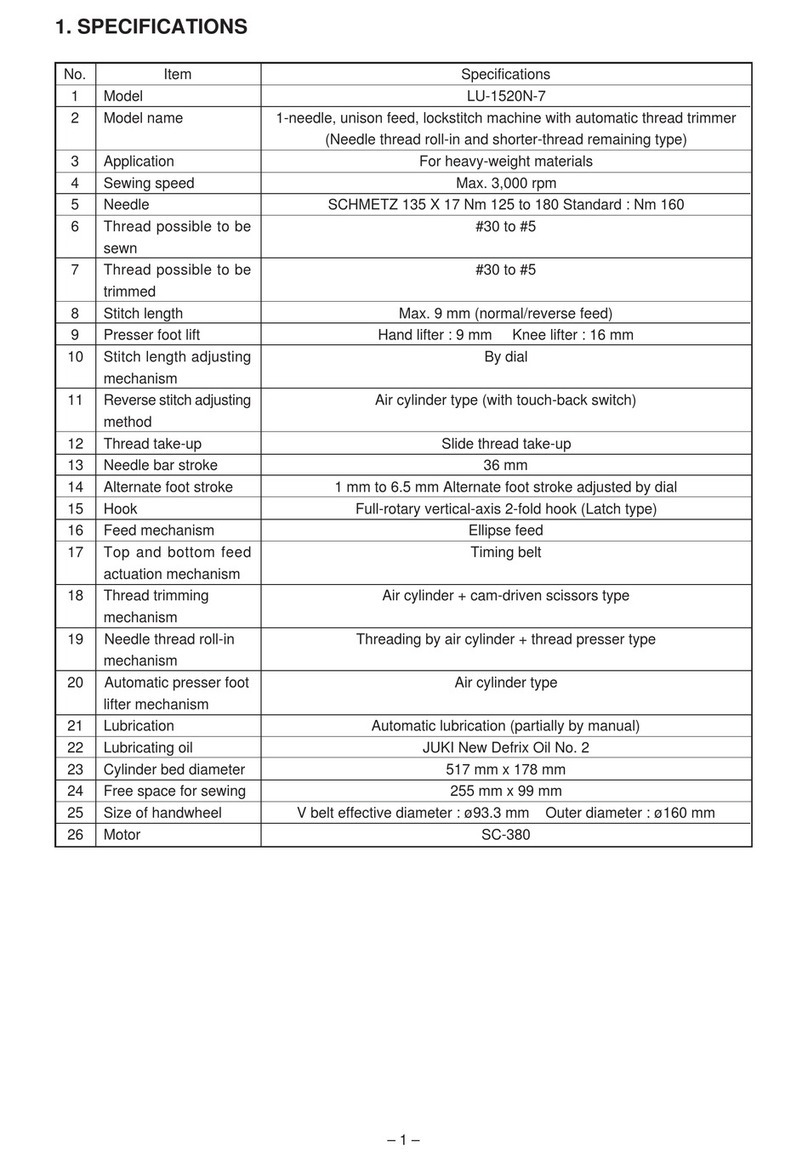

L type (thick-thread long-pitch)

The machine performs sewing with consistency with a broader range of needle counts up to #0.

In addition, it achieves the maximum stitch length of 12mm.

A triangular cam has been adopted for the feed rock cam. This

enables consistent sewing with a thread count of up to 0.

The machine comes provided as standard with a handwheel

which is larger than the S type (standard) so as to increase the

material-penetrating force of the needle.

In order to ensure an efficiency of feed (presser foot pressure)

which is larger than that provided by the S type (standard), a

double-coil spring is equipped as standard for the pressure bar

spring.

The maximum stitch length is 12mm for both forward and

reverse feed directions. In addition, the alternating vertical

movement dial is provided as standard.

Excellent operability

The basic performance (specifications) has been dramatically improved

A maximum number of revolutions of

2500sti/min (increased by 25%) is

achieved to increase productivity.

Higher lift

of the presser foot

The presser foot lift is as high as 16mm, allowing the user to

handle the material with ease.

Simple-setting of the amount of

alternating vertical movement

The vertical strokes of the presser foot and walking foot

(alternating vertical movement) can be easily changed using a

large dial mounted on the top surface of the machine head.

In addition the sewing speed is automatically adjusted with the

set value. With this feature, ideal sewing conditions are

maintained at all times.

The machine is able to support a

maximum stitch length of 9mm (12mm

for the L type).

It is now possible to factory-install the

presser foot with a center guide for

2needles at the time of delivery.

16mm