CONTENTS

1. SPECIFICATIONS ............................................................................................. 1

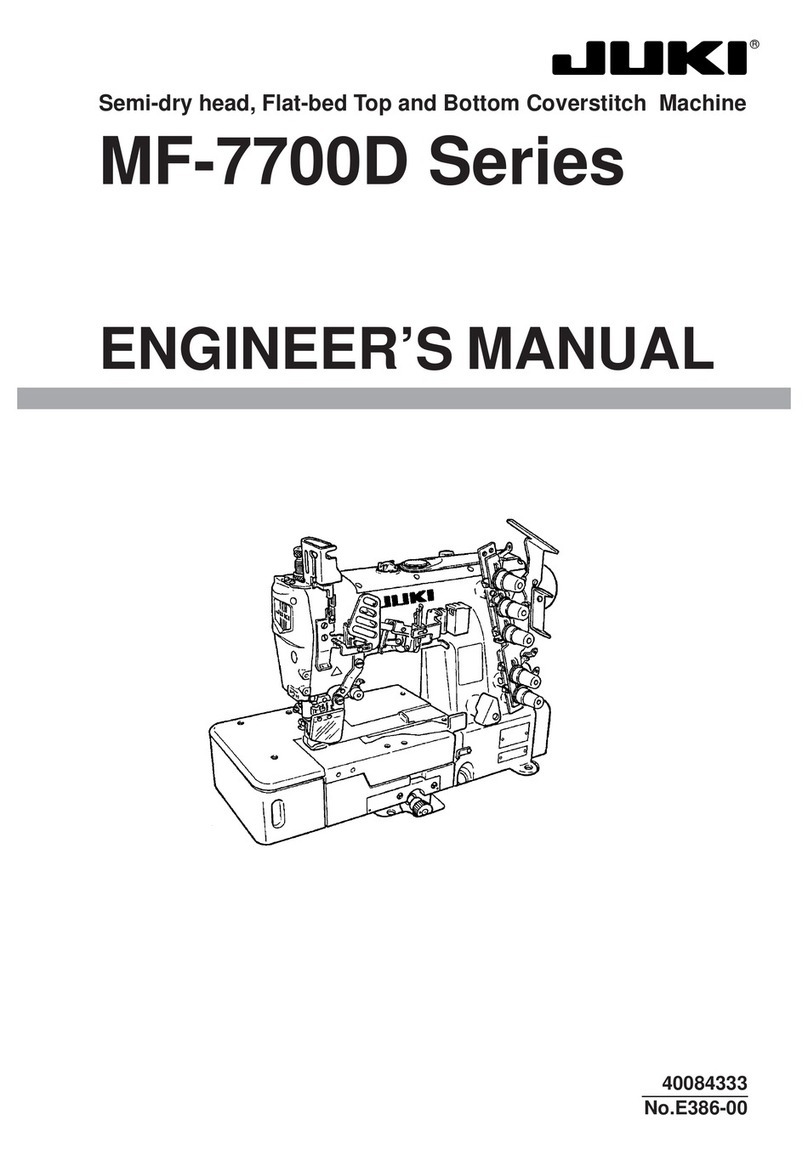

2. CONFIGURATION OF THE MACHINE COMPONENTS .................................. 2

3. MODEL NUMBERING SYSTEM ....................................................................... 3

4. MOTOR PULLEY AND BELT MF-7700 Series ................................................ 4

5. STANDARD ADJUSTMENT ............................................................................. 5

(1)Threading the machine head ........................................................................................... 5

(2) Adjusting the rocking thread take-up............................................................................. 7

(3) Adjusting the position of the needle thread guide rod ................................................. 9

(4) Adjusting the position of the thread receiver .............................................................. 11

(5) Adjusting the position of the spreader thread guide and spreader thread take-up ...... 13

(6) Adjusting the spreader .................................................................................................. 15

(7) Adjusting the timing relation between the looper and needle bar............................. 19

(8) Retuming amount of the looper .................................................................................... 21

(9) Height of the needle ....................................................................................................... 23

(10) Locus and longitudinal motion of the looper ............................................................ 25

(11) Adjusting the needle guard ......................................................................................... 27

(12) Instlling cover of the looper and needle guard after adjusting ................................ 31

(13) Adjusting the feed dog................................................................................................. 33

(14) Adjusting the feed relation .......................................................................................... 39

(15) Adjusting the presser foot........................................................................................... 41

(16) Adjusting the micro-lifter............................................................................................. 43

(17) Adjusting the looper thread cam ................................................................................ 45

(18) How to change needle bar stroke ............................................................................... 47

(19) How to change the spreader ....................................................................................... 51

(20)With reagard to lubrication .......................................................................................... 53

(21) Adjusting and setting SC-380...................................................................................... 55

6. TROUBLES AND CORRECTIVE MEASURES............................................... 57

7. DRAWING OF TABLE (SEMI-SUBMERGED TYPE) ..................................... 71