−4 −

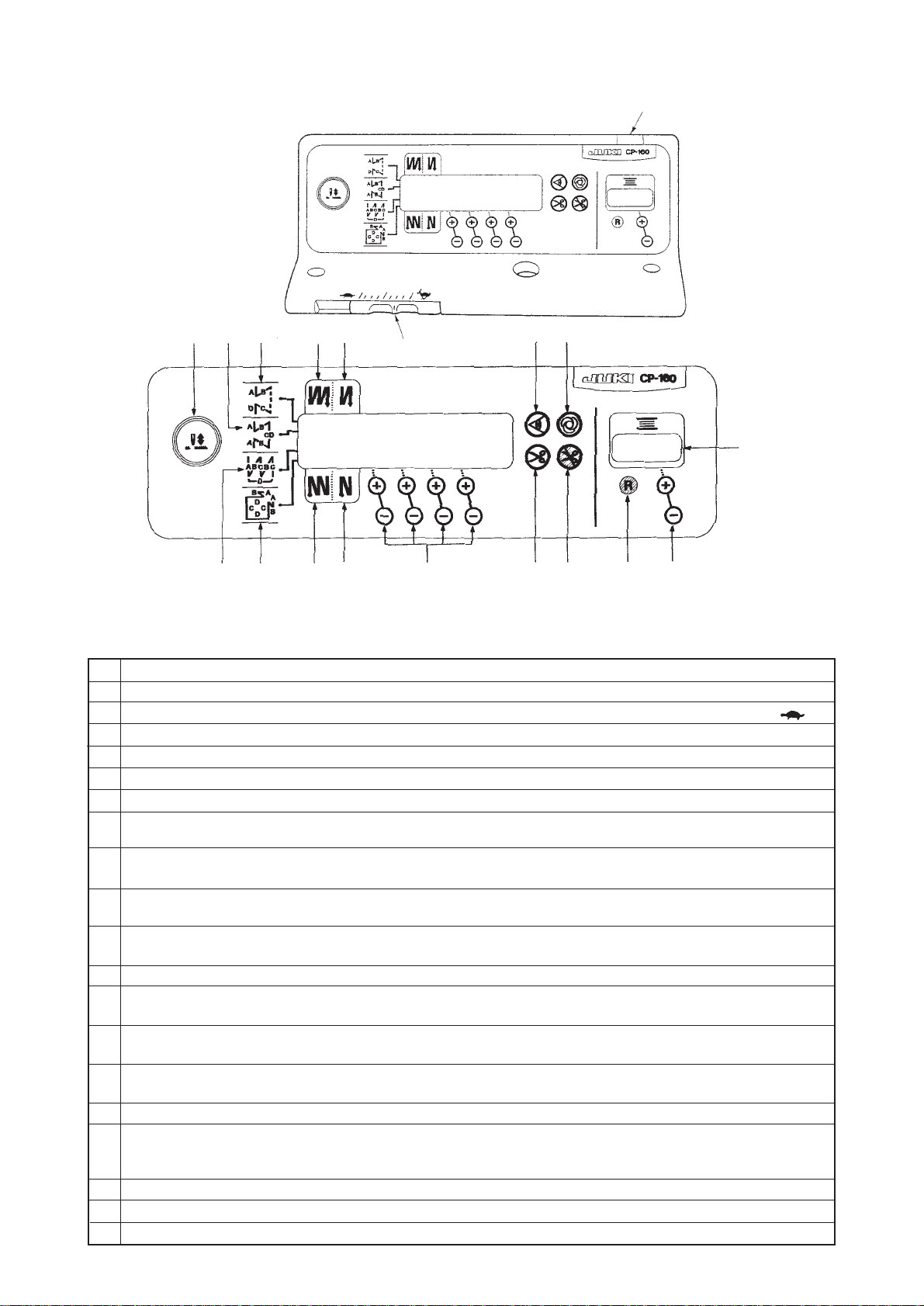

(2) Explanation of control panel CP-160

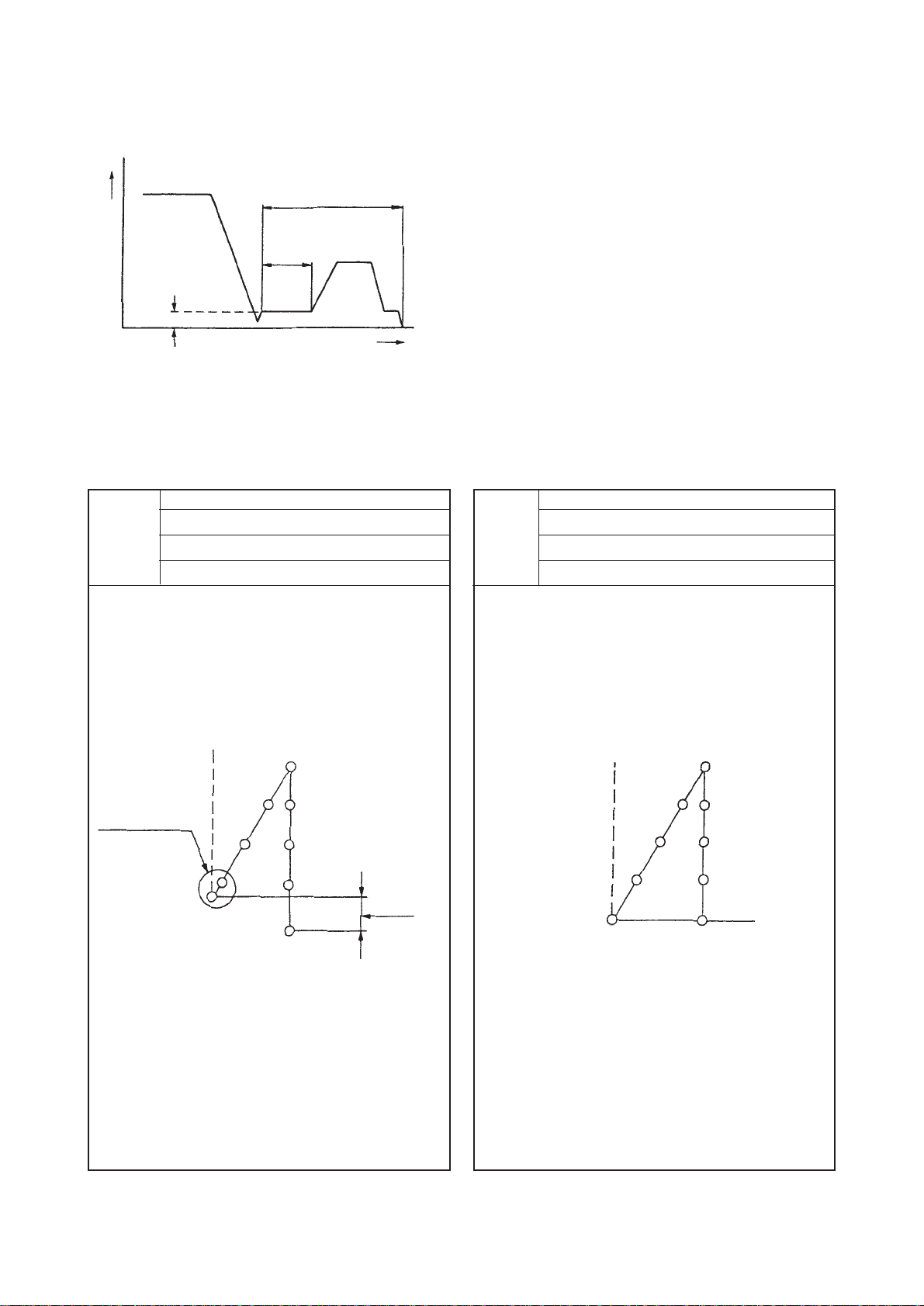

1) Reverse stitching pattern When the sewing machine performs the free stitching operation, the

machine performs the reverse stitching operation at the start and end of

sewing.

The reverse stitching operation can set the ON and OFF settings.

Furthermore, single and double reverse stitching patterns can be

selected.

Setting of number of stitches or other settings can be performed by

operating the control panel.

A, B, C and D = 0 to 19 stitches

2) Overlapped stitching pattern

The sewing machine repeats the normal stitching and reverse stitching

by the predetermined time, and performs the line bartacking. Then, the

machine makes the thread trimmer actuate and stop to complete the

overlapped stitching procedure.

Change of the number of stitches or the number of times of repetition

can be performed by operating the control panel.

A, B and C = 0 to 19 stitches

D = 0 to 9 times

3) Constant-dimension stitching pattern

The free stitching process in the reverse stitching pattern becomes the

set value of the number of stitches. The sewing machine will automatically

stop (automatically perform thread trimming if the automatic thread

trimming is selected.) after the machine finishes the predetermined

number of stitches in the process of CD.

If the automatic thread trimming is not selected, operate the touch-back

switch after the machine has automatically stopped. Then, the machine

runs at a low speed (stitch compensation operation). Also, if the pedal is

returned to its neutral position and depressed its front part again, the

sewing can be continued regardless of the setting of number of stitches.

Setting of number of stitches or selection of automatic thread trimming

can be performed by operating the control panel.

A and B = 0 to 19 stitches CD = 0 to 500 stitches

4) Rectangular stitching pattern

There are 4 operation steps in the process of constant-dimension stitching

pattern. At each operation step the sewing machine automatically stops

after sewing the predetermined number of stitches. At this time, if the

touch-back switch is operated, the sewing machine runs at a low speed

(stitch compensation operation). Also, in case of the last operation step,

if the pedal is returned to its neutral position and depressed its front part

again, the sewing can be continued regardless of the setting of number

of stitches. However, if the automatic thread trimming is set, the machine

will perform thread trimming. Setting of number of stitches or selection

of automatic thread trimming can be performed by operating the control

panel.

A and B = 0 to 19 stitches C and D = 0 to 99 stitches