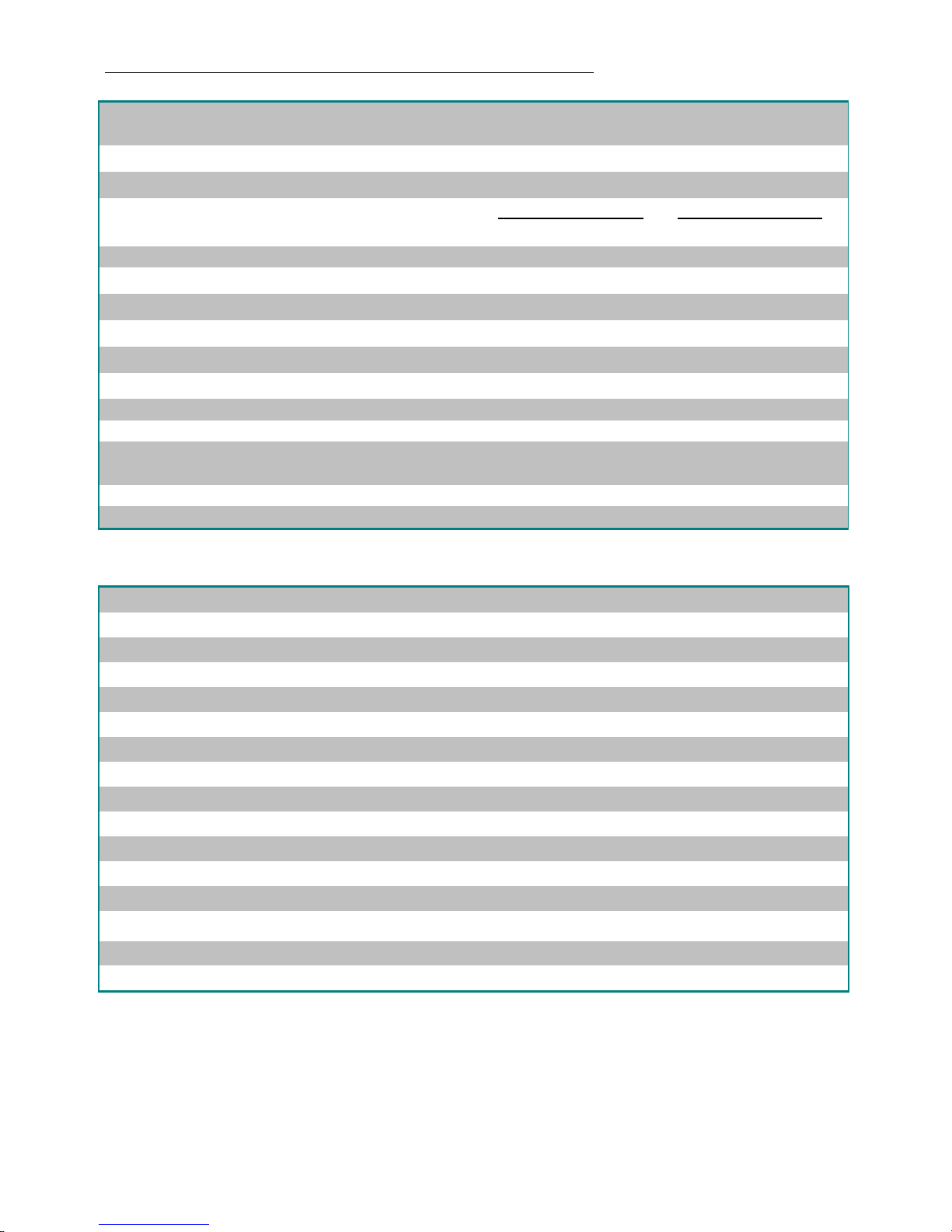

9.4. MENU CONFIG - Configuration of unit....................................................................40

9.4.1.Remote control via the serial interface................................................................41

9.4.2.Keypad control or setpoint setting via the analog input.......................................42

9.4.3.AUTOSTART......................................................................................................42

9.4.4.OFF-MODE ........................................................................................................43

9.4.5.ACTVAR - actuating variable..............................................................................43

9.4.6.Setting of clock and date ....................................................................................44

9.4.7.RESET – Factory settings ..................................................................................44

9.5. MENU CONTROL – Control characteristics and parameters ..................................44

9.5.1.CONTROL – Control INTERNAL / EXTERNAL...................................................46

9.5.2.SELFTUNING.....................................................................................................47

9.5.3.Dynamic internal.................................................................................................47

9.5.4.Control parameters– XP-, TN-, TV- INTERNAL..................................................48

9.5.5.COSPEED - external..........................................................................................49

9.5.6.Control parameters – XPU-, XP-, TN-, TV- EXTERNAL......................................49

9.6. MENU SERIAL - BAUDRATE, HANDSHAKE, PARITY...........................................50

9.7. MENU ATC - Absolut Temperature Calibration.......................................................51

9.7.1.ATC SENSOR - INTERNAL / EXTERNAL..........................................................53

9.7.2.ATC STATUS - YES / NO...................................................................................53

9.7.3.CALIBRATION TYPE: 1 -/ 2 -/ 3 POINT .............................................................54

9.7.4.Example: 3-point calibration for internal control .................................................55

9.8. MENU LIMITS.........................................................................................................57

9.8.1.Limits for internal control.....................................................................................58

9.8.2.Limits for external control....................................................................................58

9.9. MENU IN/OUT – Analog inputs/outputs (Option).....................................................60

9.9.1.Outputs of the connector - REG+E-PROG..........................................................63

9.9.2.Input of the connector - REG+E-PROG..............................................................64

9.9.3.ALARM-output / Stand-by-input..........................................................................66

10. Troubleshooting guide / error messages......................................................................68

11. Electrical connections..................................................................................................71

12. Remote control............................................................................................................73

12.1. Setup for remote control..........................................................................................73

12.2. Communication with a PC or a superordinated data system ...................................73

12.3. List of commands....................................................................................................74

12.4. Status messages ....................................................................................................77

12.5. Error messages.......................................................................................................77

13. Installation of electronic module...................................................................................78

14. JULABO Service – Online remote diagnosis................................................................79

15. Cleaning / repairing the unit.........................................................................................80

16. WARRANTY PROVISIONS.........................................................................................81

4