3

1Foreword ............................................................................................. 5

2About this manual.............................................................................. 6

2.1 Original JULABO spare parts.......................................................... 6

2.2 Accessories..................................................................................... 6

2.3 Warnings ......................................................................................... 7

2.4 Symbols used.................................................................................. 8

3Intended use ....................................................................................... 8

4Safety................................................................................................... 9

4.1 Safety instructions........................................................................... 9

4.2 Safety symbols.............................................................................. 11

4.3 Safety function............................................................................... 11

5Product description.......................................................................... 12

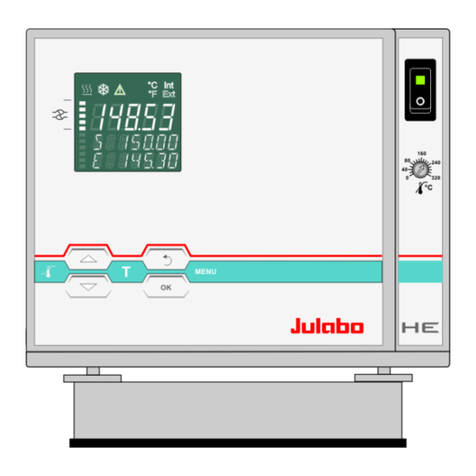

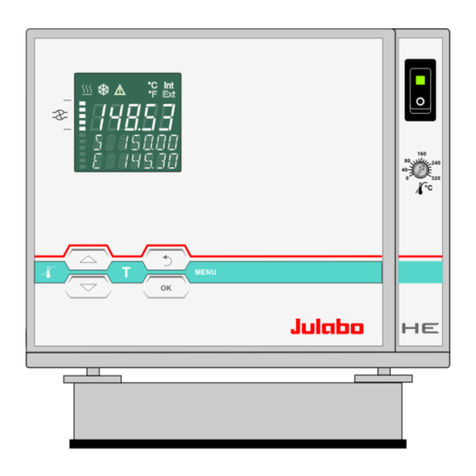

5.1 Product overview........................................................................... 12

5.2 Operating and functional elements ............................................... 13

5.2.1 Key description......................................................................... 14

5.3 Alarm messages............................................................................ 14

5.4 Technical data............................................................................... 15

5.4.1 Material of parts that come into contact with the medium........ 17

5.4.2 Bath fluids................................................................................. 17

6Transport and installation ............................................................... 18

6.1 Transporting the device.................................................................18

7Initial operation................................................................................. 19

7.1 Connect the device to the power supply.......................................19

7.2 Fill device ...................................................................................... 19

8Operation........................................................................................... 20

8.1 Switch on the unit.......................................................................... 20

8.2 Switch off the unit.......................................................................... 20

8.3 Configuring setpoint temperature.................................................. 20

8.4 Start temperature control application ............................................ 21

8.5 Activate autostart function.............................................................21

8.6 Setting the timer ............................................................................ 22

8.7 Adjusting the temperature sensor (ATC).......................................22

www. .com information@itm.com1.800.561.8187