SAFETY

Safety instructions for maintenance,

assembly and repair work

Before cleaning, maintenance and repair

work, switch off the units and secure them

against unintentional restarting.

Regularly check loose cables for damage.

Have damaged cables replaced immediately.

Connecting cables must be laid in such a way

that they are protected against mechanical,

chemical and thermal inuences.

Selection of personnel and qualification

The personnel for operation and maintenance

must have the appropriate qualications for

this work.

The area of responsibility, competence

and supervision of the personnel must be

regulated by the supervision of the operators.

Connection and repair work may only be

carried out by qualied personnel.

SAFETY

INSTRUCTIONS

Safety instructions classify situations as

well as their type and severity of

consequences if the measures to avoid the

danger are not followed.

LIMITATION OF

LIABILITY

All technical information, data and

instructions for the operation and

maintenance of the signal lantern contained

in these user manual are correct at the

time of printing and are given to the best

of our knowledge, taking into account our

experience and knowledge to date.

We reserve the right to make technical

changes as part of the further development

of the signal lantern covered in this

user manual.

Therefore, no claims can be derived from the

information, illustrations and descriptions.

We accept no liability for damage and

malfunctions caused by operating errors,

non-observance of this user manual or

improper repairs. We strictly point out that

spare parts and accessories not supplied by

us have not been tested and approved. Any

liability for damage resulting from the use of

non-original spare parts and accessories is

excluded.

Opening sealed surfaces will invalidate

the warranty / guarantee claims against

the manufacturer. Furthermore, any

unauthorised conversions and modications

to the signal lantern are not permitted for

safety reasons and exclude any liability for

resulting damage.

Claims for damages, regardless of the legal

grounds on which such claims are derived,

are excluded.

TERMS

Operator

The term "operator" refers to anyone who

owns or is entrusted by the operator of the

signal lantern with specic tasks relating to

operation, running, maintenance, repair and

other tasks.

Skilled person (specialist)

A "specialist" is dened as someone who,

due to his technical training, has expert

knowledge and experience as well as

knowledge of the relevant regulations,

accident prevention regulations and operating

conditions and who can assess the work

assigned to him and recognise and avoid

possible hazards.

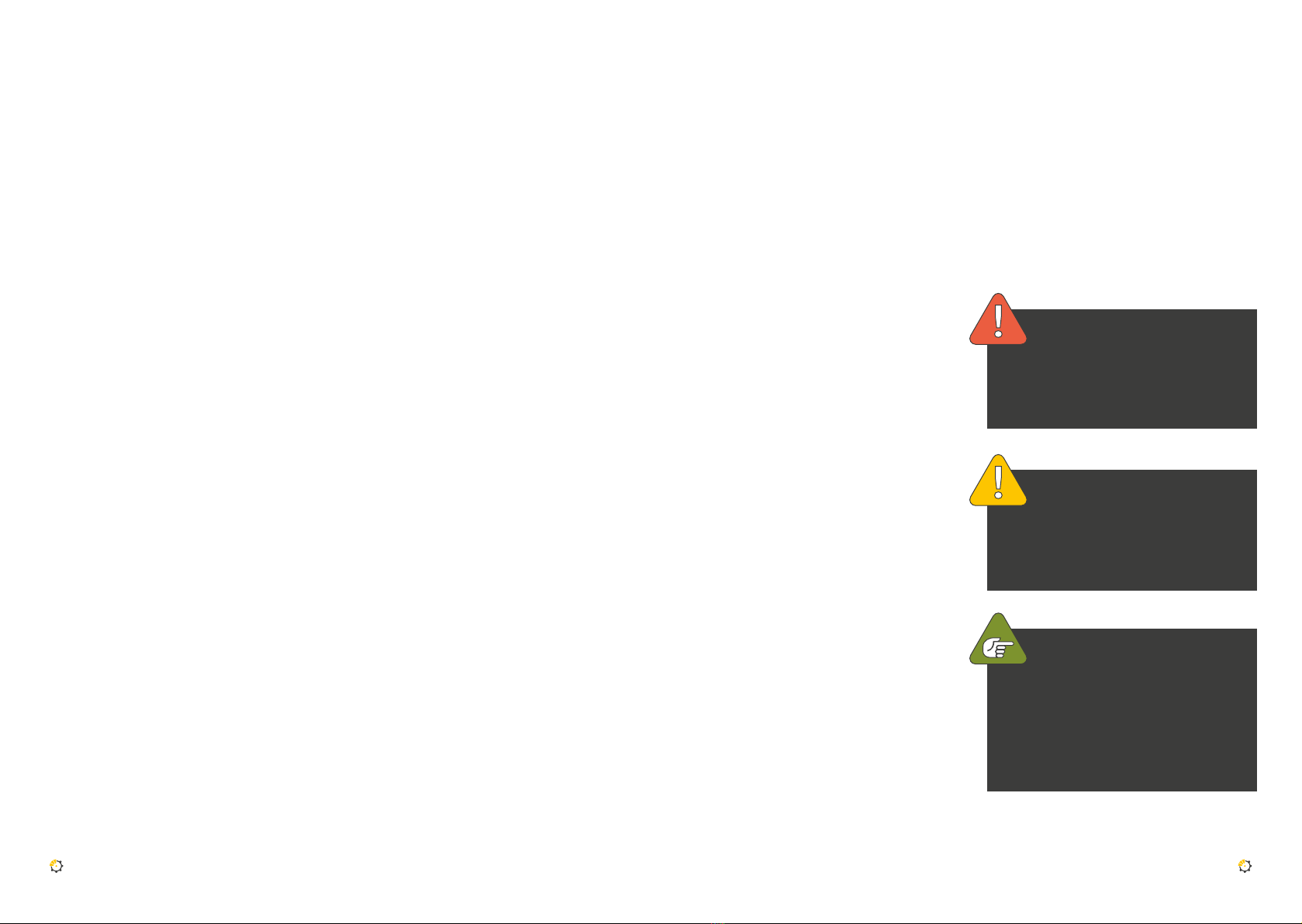

Warning

Warnings signal immediate

hazards that may result in serious

injury or death.

Caution

Cautions signal potential hazards that

may result in minor injury or damage

to the product.

Note

Notes provide relevant instructions

for better and easier handling of the

product. Furthermore, supplementary

information on the product may be

explained here.

54