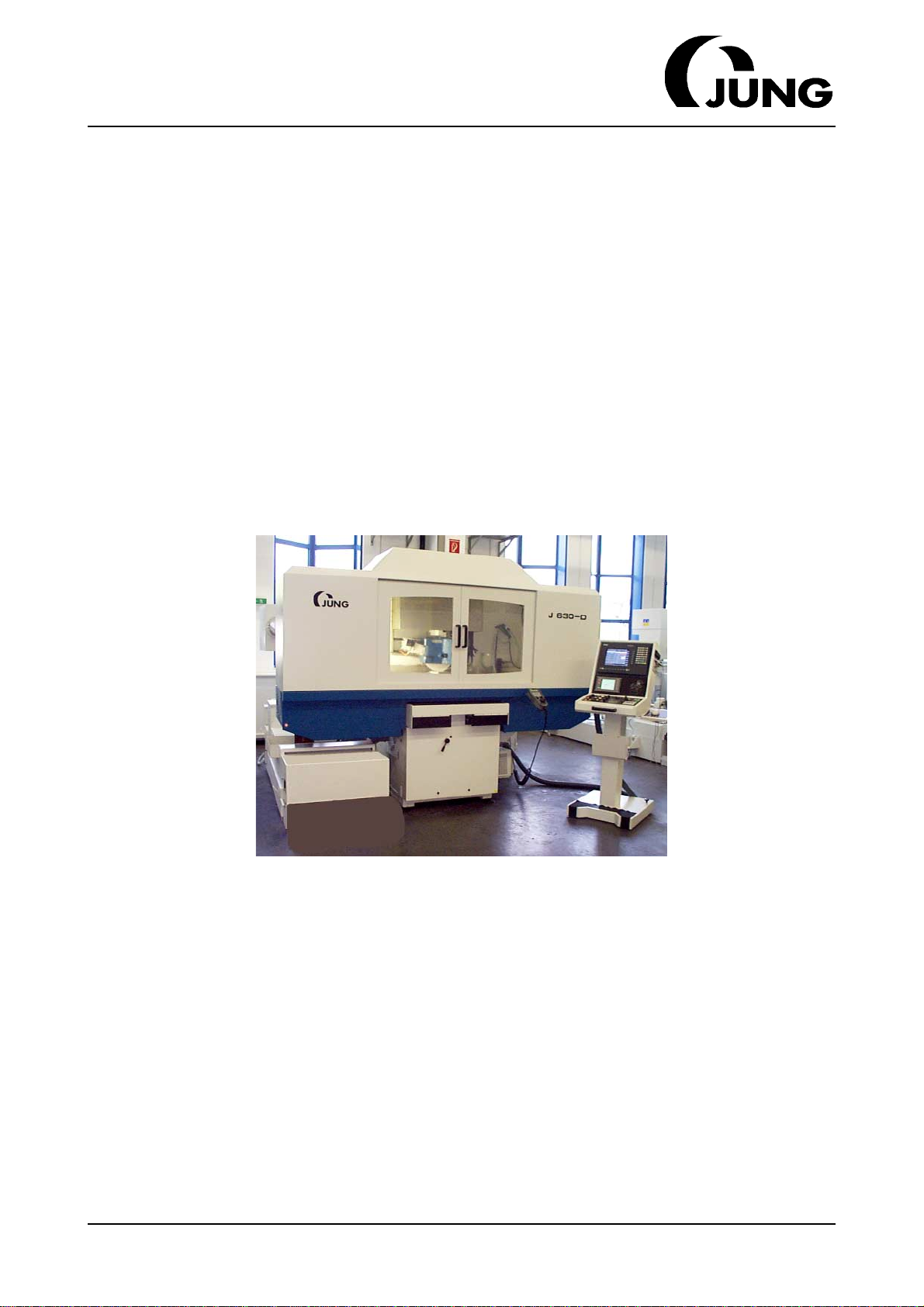

J630D

ii 26.7.02

4.3.1.2 Switching the grinding spindle motor off ................................................62

4.3.1.3 Positioning the axes at the normal feed rate or in rapid traverse mode.62

4.3.1.4 Positioning the axes incrementally.........................................................62

4.3.1.5 Starting the automatic reciprocating function.........................................63

4.3.1.6 Stopping the automatic reciprocating function .......................................63

4.3.1.7 Activating a manual infeed during an automatic reciprocating motion...63

4.3.1.8 Setting the reversing positions for the reciprocating motion in

the X-axis directly...............................................................................................64

4.3.1.9 Setting the reversing positions for the reciprocating motion in

the Z-axis directly...............................................................................................65

4.3.1.10Teaching an X- or Z-axis reversing position with the remote

control panel.......................................................................................................66

4.4 Automatic mode ............................................................................................................67

4.4.1 Special functions in automatic mode..................................................................67

4.4.1.1 Interrupting a program cycle (26) and continuing machining at the

breakpoint (not possible with creep-feed grinding technology)..........................67

4.4.1.2 Program cycle interrupted during a dressing cycle ................................68

4.4.1.3 Cancelling a function..............................................................................68

4.4.1.4 Measurement.........................................................................................68

4.4.2 Sequence of operations in an automatic program cycle....................................69

5. Functions of the machine....................................................................................................71

5.1 Functions of the control unit / machine..........................................................................71

5.1.1 Important warning for all programs ....................................................................72

5.1.2 Function tree structure of the Machine Jung module in setting-up and semi-auto-

matic mode....................................................................................................................73

5.1.3 Function tree structure of the Machine Jung module in automatic mode...........75

5.1.4 Machine Jung module........................................................................................76

5.1.4.1 System data ...........................................................................................78

5.1.4.2 Statistics.................................................................................................79

5.1.4.3 Simulation ..............................................................................................80

5.1.4.4 Program overview..................................................................................81

5.1.5 Function tree structure of the Program Jung module.........................................83

5.1.6 Program Jung module........................................................................................85

5.1.6.1 Function tree structure of the File Manager...........................................87

5.1.6.2 File manager..........................................................................................89

5.1.7 Bereich Dienste Bedienbaum-Struktur...............................................................93

5.1.8 Service module ..................................................................................................95

5.2 Traversing to the reference point ..................................................................................97

5.3 Tool management .........................................................................................................99

5.3.1 Function tree structur.........................................................................................99

5.3.2 Tool management generally.............................................................................101

5.3.3 Grinding wheel management...........................................................................101

5.3.4 Dresser management.......................................................................................105

5.4 Setting actual values...................................................................................................109

5.4.1 Setting actual values for table dressing ...........................................................109

5.4.1.1 Setting actual values with a single diamond /PA30/130T (optional) ....110

5.4.1.2 Probing control in the AT Y-axis and the AT Z-axis (optional).............112

5.4.2 Setting actual values for the AF65 dressing head (optional)............................114

5.4.2.1 Probing manually with confirmation .....................................................115

5.4.3 Setting actual values for the PA 31K dressing head (optional)........................115

5.4.4 ISetting actual values for grinding....................................................................117

5.4.4.1 Probing control in the AT Y-axis and the AT Z-axis (optional).............118

5.5 Creating and modifying grinding programs .................................................................121

5.5.1 Grinding program functions..............................................................................121

5.5.1.1 Automatic probing in the grinding program ..........................................122

5.5.2 Function tree structure for surface grinding .....................................................123

5.5.3 Surface grinding...............................................................................................125