Könner & Söhnen KS 15TKG 52/35 User manual

Gasolline Log Splitter

Please, read this manual

carefully before use! Owner’s Manual

KS 15TKG 52/35

KS 27THG 65/55

EN

INTRODUCTION

SAFETY INFORMATION 1

Thank you for your purchase of Könner & Söhnen products. This manual contains a brief description of

safety, use and debugging. More information can be found on the ocial manufacturer’s website in the

support section: ks-power.de/betriebsanleitungen.

You can also go to the support section and download the full version of the manual by scanning the QR

code, or on the website of the ocial importer of Könner & Söhnen products: www.ks-power.de/en

The manufacturer reserves the right to make changes to the generators, which may not be reected in this

manual. Pictures and photos of the product may vary from its actual appearance. At the end of this manual,

you will nd contact information which you are free to use in case of any issues.

All data specied in this owner’s manual are the most up to date at the time of its publication. The current

list of service centers can be found on the website of the ocial importer: www.ks-power.de/en

We care about the environment, therefore, we consider it expedient to saveWe care about the environment, therefore, we consider it expedient to save

paper and leave in print a short description of the most important sections.paper and leave in print a short description of the most important sections.

Be sure to read the full version of the manual before

getting started!

Failure to follow the instructions marked with this sign

may lead to serious injury or death of the operator or

third parties.

Useful information on operation of the machine.

ATTENTION – DANGER!

IMPORTANT!

Please, read this manual carefully before use!

WARNING!

PROTECTING YOURSELF AND THOSE AROUND YOU 1.1

This is a high-powered machine, with moving parts

operating with high energy. You must operate the

machine safely. Unsafe operation can create a number

of hazards for you, as well as anyone else in the nearby

area.

WARNING!

Safety symbols and description of inscriptions can be found in the full web version.Safety symbols and description of inscriptions can be found in the full web version.

Always take the following precautions when using

this machine:

• Always wear protective goggles or safety glasses

with side shields while using the log splitter to

protect your eyes from possible thrown debris.

• Avoid wearing loose clothing or jewelry, which

can catch on moving parts.

• We recommend wearing gloves while using the

log splitter.

• Wear shoes with non-slip treads when using your

log splitter. Do not use the machine while barefoot

or wearing open toed sandals.

•Wear long pants while operating the log splitter.

• Keep bystanders at least 50 feet away from

your work area at all times. Stop the motor when

another person or pet approaches.

• Never allow children to operate the log splitter.

• Keep in mind that the operator or user is

responsible for accidents or hazards occurring to

other people, their property, and themselves.

www.ks-power.de/en |1

GETTING STARTED 3

CHECKING THE FUEL LEVELCHECKING THE FUEL LEVEL

1. Unscrew the fuel cap and check the fuel level in the tank.

2. Fill the fuel tank to the fuel filter level.

3. Tighten the fuel cap securely.

SAFETY WITH GASOLINE - POWERED MACHINES 1.2

Gasoline is a highly flammable liquid. Gasoline gives off

flammable vapor that can be easily ignited and cause a

fire or explosion.

WARNING!

Always follow these precautions:

• Never run the engine in an enclosed area or with-

out proper ventilation as engine exhaust contains

carbon monoxide, which is an odorless, tasteless,

and a deadly poisonous gas.

• Replace rubber fuel lines and grommets when

worn or damaged and after 5 years of use.

• Fill the fuel tank outdoors with the engine o and

allow the engine to cool completely.

• Allow the engine to cool completely before stor-

ing. Never store a machine with gasoline in the tank

or a fuel container.

• Never make adjustments or repairs with the en-

gine running. Shut down the engine, disconnect

the spark plug wire while keeping it away from

the spark plug to prevent accidental starting, and

then wait 5 minutes before making adjustments or

repairs.

• Never tamper with the engine governor setting.

• Never cover the machine while the muer is still

hot.

• Do not operate the engine with the air lter or

the carburetor air intake cover removed. Removal

of such parts could create a re hazard. Do not use

ammable solutions to clean the air lter.

• The muer and engine become very hot and can

cause severe burns; do not touch them.

SPECIFICATIONS 2

Model KS 15TKG 52/35 KS 27THG 65/55

Log splitter type kinetic hydraulic

Engine power 6.5 HP 6.5 HP

Splitting force 15 ton 27 ton

Engine type gasoline gasoline

Engine model KS 230 KS 230

Max. splitting length 520 mm 650 mm

Max. splitting diameter 350 mm 550 mm

Cycle time ~ 2 seс. ~ 15 seс.

Operating position horizontal vertical/horizontal

Flywheel speed 450 U/min 3.6 l

Fuel tank volume 3.6 l 20 l

Crank case volume 0.6 l 0.6 l

Wheels 12’’ 16’’*4.8-8 4, support wheel with brake

Gross dimensions (L*W*H) 1400x380x610 mm 2250x505x570 mm

Gross weight 110 kg 295 kg

Protection class IP54M IP54M

The diameter listed is indicative of the maximum sug-

gested size. A small log can be dicult to split when it

contains knots or a particularly tough ber.

IMPORTANT!

www.ks-power.de/en |2

STARTING THE ENGINESTARTING THE ENGINE

Before starting the engine, make sure the switch is in the “I” (ON) position (see the pictures below). Turn

the rotary engine speed dial to MAX. Set the engine switch to the “CHOKE” position. Grasp the starter

handle and slowly pull it until resistance is felt, then pull it with a rapid movement all the way. Repeat the

operation until the engine starts. After starting the engine, allow the rope to retract without throwing the

starter handle. Put the flaps in the “RUN” position.

Recommended fuel:Recommended fuel: only unleaded gasoline.

Fuel tank volume:Fuel tank volume: see specifications table.

Wipe up spilled fuel immediately with a clean, dry, soft

cloth, as the fuel may harm painted surfaces or plastic

parts.

IMPORTANT!

CHECKING THE OIL LEVELCHECKING THE OIL LEVEL

The log splitter is transported free of motor oil. Do not start the engine until it is filled with sufficient amount

of motor oil.

1. Unscrew the oil dipstick and wipe it out with a clean cloth.

2. Insert the dipstick without screwing it in.

3. Check the oil level by a mark on the oil dipstick.

4. Add oil if its level is below the mark on the oil dipstick.

5. Screw on the dipstick.

Recommended motor oil:Recommended motor oil: SAE 10W30, SAE 10W40.

Recommended motor oil grade:Recommended motor oil grade: API Service SG type or higher.

Motor oil quantity:Motor oil quantity: see specifications table.

FILL TO HEREFILL TO HERE

Use only unleaded gasoline. Using leaded gasoline can

cause serious damage to the inside of the engine.

IMPORTANT!

COMMISSIONINGCOMMISSIONING

1. Fill the crankcase with engine oil. The recommended amount of oil for each model is indicated in the

specification chart.

2. Check oil level with an oil dipstick. It should be between the MIN and MAX marks on the oil dipstick.

3. Check fuel level.

4. Check the air filter for correct installation.

IN THE FIRST 20 OPERATING HOURS, THE FOLLOWING REQUIREMENTS SHOULD BE MET:IN THE FIRST 20 OPERATING HOURS, THE FOLLOWING REQUIREMENTS SHOULD BE MET:

1. After the first 20 operating hours, be sure to change the oil. It is better to drain motor oil while the engine

is still hot after operation to ensure quick and complete oil draining.

2. Check and clean the air filter and spark plug.

Engine switch

OFFON

air damper

fuel valve

OpenClosed

OpenClosed

www.ks-power.de/en |3

Always follow these notices:

• A rapid movement of the engagement handle is

necessary for the rack and pinion to engage and

disengage fully without damage.

• The engagement handle should never be stopped

in any location between the fully forward or fully

backward positions.

• Do not hold the handle in the forward position

when the ram stops moving forward. Always pull

the engagement handle RAPIDLY to the back (au-

to-retract) position as soon as the log is split or

when the ram is at the end of the stroke or when

the ram stops moving forward due to a tough log.

1. Place the log on the Log Splitter. Grasp the log

on the sides near the middle of the block. Center

the log, side-to-side, on the rail of the Log Splitter.

Do not place the log tightly to the cutting knife. The

recommended distance from the cutting knife is

4-5 cm.

• Do not reach or step across the beam while the log

splitter is running. This is a very UNSAFE method which

could cause personal injury or even death.

WARNING!

• Never attempt to split wood across the grain. The log

splitter was not designed for cross-grain splitting. Doing

so could damage the log splitter and may cause personal

injury.

CAUTION!

The kinetic log splitter operates differently than a

hydraulic splitter. Not operating the machine properly

will result in damage to the machine.

The engagement handle must be held fully in the split

position against the hard stop when splitting. Failure to

do so may result in kickback of the handle.

CAUTION!

NOTICE

• Make sure both ends of the log you are splitting are cut as square as possible. This will

prevent the log from sliding out of position while under pressure.

2. With one hand, actuate and hold the safety lever

towards you, then RAPIDLY actuate the engagement

handle fully towards the engine until it contacts the

hard stop and hold firmly until the log is split.

3. IMMEDIATELY AFTER the log is split, actuate and

hold the engagement handle in the auto-retract

position to allow the ram to return. If the ram stops

before the end of the stroke while splitting a tough

log, quickly actuate the engagement handle back to

the auto-retract position. Let the ram return and

allow the flywheels to gain momentum for another

full power split.

STOPPING THE ENGINESTOPPING THE ENGINE

To stop the engine, turn the switch to the “OFF” position. Turn the fuel valve to the “CLOSED” position.

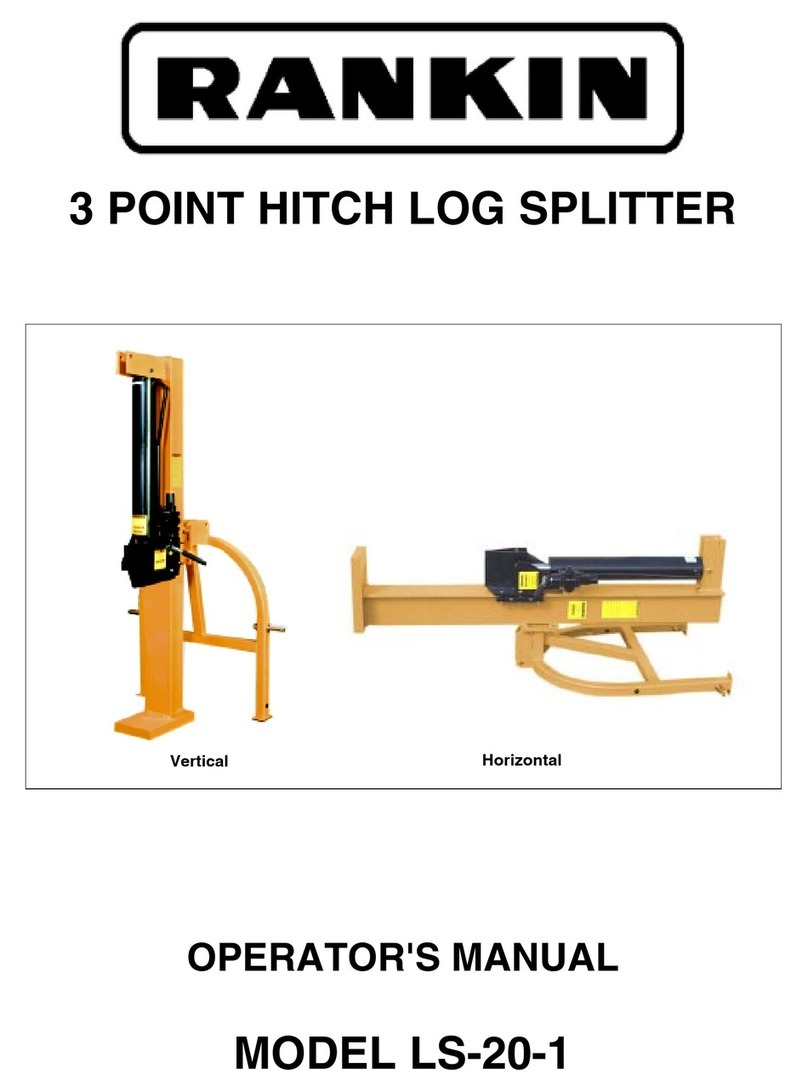

KINETIC LOG SPLITTER KS 15TKG 52/35

OPERATION INSTRUCTIONS 4

HYDRAULIC LOG SPLITTER KS 27THG 65/55

OPERATION INSTRUCTIONS 5

1). Load a log onto the beam and against the endplate.

2). Serious accidents can happen when other people are allowed inside the work zone. Keep everyone else

out of the work zone while operating the control valve.

3). Make sure hands are clear of crush hazard zones.

4-5 cm

Hands on Sides

of Wood

www.ks-power.de/en |4

4). Push the control valve handle FORWARD with two hands to split the log.

5). Push the control valve handle BACKWARD with two hands to return wedge to its original position.

6). Remove the split wood from the work zone.

Rotate rear leg down and

slide the lock pin

1. Pull out the beam lock pin.

2. Lift the beam at the end side and rotate it down slowly.

Beam and the handle

Beam lock pin

FOR HORIZONTAL USEFOR HORIZONTAL USE

FOR VERTICAL USEFOR VERTICAL USE

www.ks-power.de/en |5

KS 15TKG 52/35 COMPONENTS IN THE PACKAGE 6

HOW TO SPLIT THE LOG WITH SLANTED SURFACE 5.1

WRONG BETTER BEST

FOR VEHICLE TOWINGFOR VEHICLE TOWING

Rotate the rear leg and

slide the lock pin

Hook safety chain to tow

vehicle

table for log splitter

(optional accessory)

www.ks-power.de/en |6

STEP 1STEP 1

KINETIC LOG SPLITTER KS 15TKG 52/35 ASSEMBLY 7

STEP 2STEP 2

4-M10x25 Hex bolt

4ø10 Flat washer

4ø10 Spring washer

www.ks-power.de/en |7

STEP 3STEP 3 STEP 4STEP 4

Vee Belt

4-M6x16

Hex bolt

4-26 Flat washer

STEP 5STEP 5

2-M8x25 Hex bolt

2ø8 Flat washer

2ø8 Spring washer

KS 27THG 65/55 MACHINE COMPONENT DEFINITIONS 8

1

2

98

10

4

6

5

3

7

1). Coupler. Attaches the log splitter

to your vehicle. Couplers vary with the

market.

2). Hydraulic Cylinder. It is rated to

3500 psi.

3). Control valve handle. Use the

control valve handle to move the wedge

slide forward and backward. A two-han-

dle option is only available for European

market.

4). Wedge. The wedge features a taper

that makes splitting easier; welded cross

can be put on.

www.ks-power.de/en |8

HYDRAULIC LOG SPLITTER KS 27THG 65/55 ASSEMBLY 9

STEP 1: ASSEMBLE THE WHEELSTEP 1: ASSEMBLE THE WHEEL

Fix the wheel to the oil tank by the slotted nut , cotter pin and attach the dust cap.

5). Log cradle. Keeps the log on the beam without operator assistance. Can be upgraded to a bigger table.

6). Engine. The air cooled engine powers the hydraulic pump.

7). Tires. Maximum rated speed is 30 mile per hour.

8). Gear pump. The gear pump makes the hydraulic oil ow through the system.

9). Leg. The leg supports the log splitter while operating. The leg should be raised while towing(see Operation Instruc-

tions).

10). Safety chains. A safety feature to prevent detachment of log splitter while towing.

Spring washer 10

Fix the support outrigger leg to the tow bar using the catch

pin, bolt M10X75,lock nut M10 and R pin.

For model with jockey wheel

Lock Nut 12

Washer 12

Washer 10

Tow bar

Washer 12

Bolt

М12х75

Bolt М10х25

Jockey wheel

STEP 2:STEP 2:

ATTACH THE TOW BAR AND SUPPORT LEGATTACH THE TOW BAR AND SUPPORT LEG

STEP 3:STEP 3:

ATTACH THE TOW BAR TO THE OIL TANKATTACH THE TOW BAR TO THE OIL TANK

Fix the tow bar to the oil tank using hex bolts M12 and

lock nuts M12.

www.ks-power.de/en |9

Other manuals for KS 15TKG 52/35

1

This manual suits for next models

1

Table of contents

Other Könner & Söhnen Log Splitter manuals