Table Of Contents

1 Introduction 4

1.1 How to Use this Manual . . . . . . . . . . . . . . . . . . . . . 4

1.2 Safety Precaution . . . . . . . . . . . . . . . . . . . . . . . . . 4

1.3 Recycling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2 Unpacking and Inspection 6

3 The Robot and Its Accessories 7

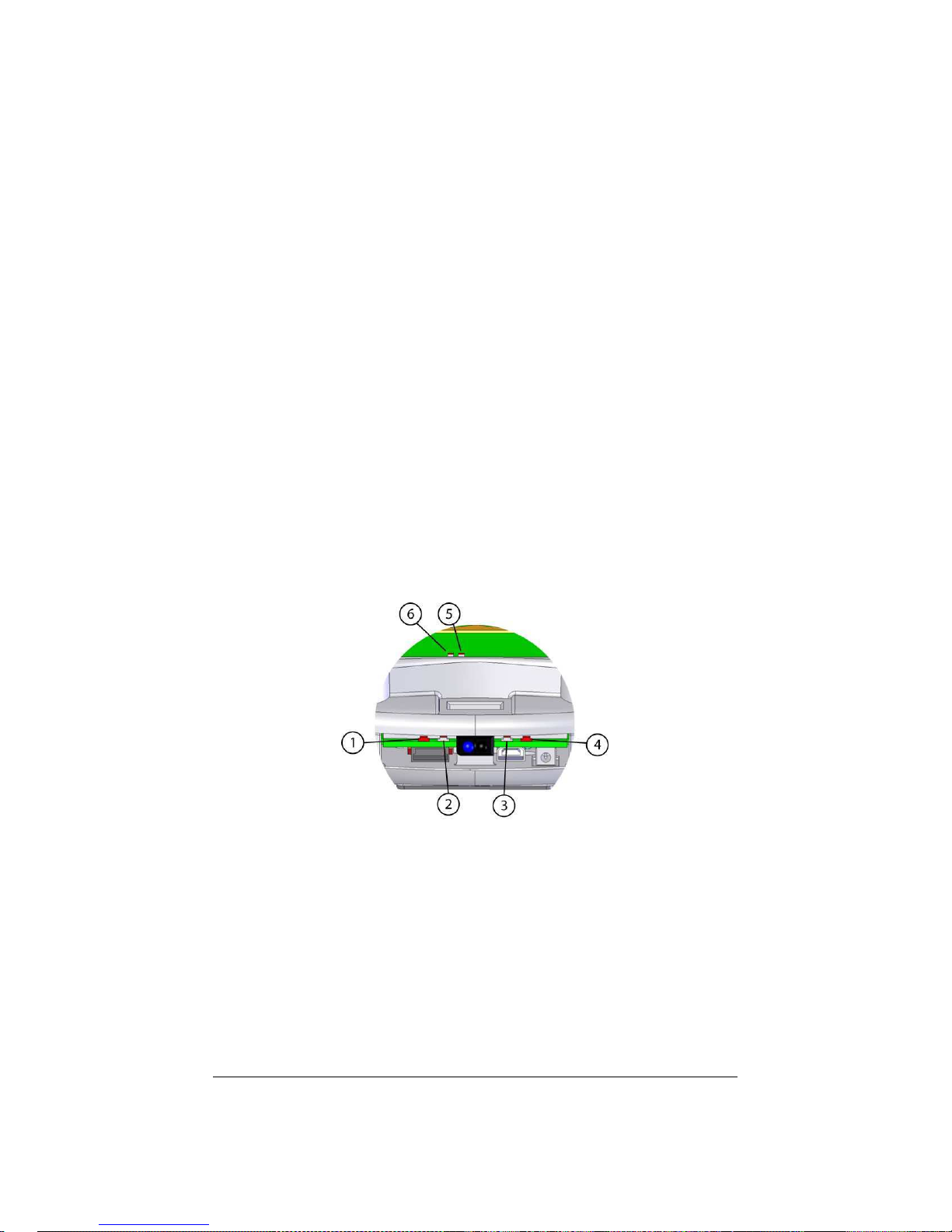

3.1 The Khepera III Robot . . . . . . . . . . . . . . . . . . . . . 7

3.1.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1.2 ON-OFF Battery Switch . . . . . . . . . . . . . . . . . 8

3.1.3 Indication LEDs . . . . . . . . . . . . . . . . . . . . . 8

3.1.4 Serial connector . . . . . . . . . . . . . . . . . . . . . 9

3.1.5 Cable unroller connector . . . . . . . . . . . . . . . . . 10

3.1.6 USB connector . . . . . . . . . . . . . . . . . . . . . . 10

3.1.7 How to plug a KoreBotLE . . . . . . . . . . . . . . . . 11

3.2 Motors and motor control . . . . . . . . . . . . . . . . . . . . 12

3.2.1 Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

3.3 Infra-red Proximity sensors . . . . . . . . . . . . . . . . . . . 16

3.3.1 Ambient light measurements . . . . . . . . . . . . . . 17

3.3.2 Reflected light measurements (proximity) . . . . . . . 17

3.4 Ultrasonic sensors . . . . . . . . . . . . . . . . . . . . . . . . 18

3.5 Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3.6 Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

4 Connections 20

4.1 Configuration for batteries charge . . . . . . . . . . . . . . . . 20

4.2 Configuration for Robot-Computer Communication in standalone 21

4.3 Configuration for Robot-Computer Communication with KoreBotLE 22

4.3.1 Serial link . . . . . . . . . . . . . . . . . . . . . . . . . 22

4.3.2 USB link . . . . . . . . . . . . . . . . . . . . . . . . . 23

4.4 Bluetooth Communication . . . . . . . . . . . . . . . . . . . . 24

4.4.1 Bluetooth communication with KheperaIII . . . . . . 24

4.4.2 Bluetooth communication with KoreBotLE . . . . . . 25

4.4.3 Log On the KoreBotLE with a Bluetooth connection . 25

K-Team S.A. 2