8| Kaden Owner’s Manual

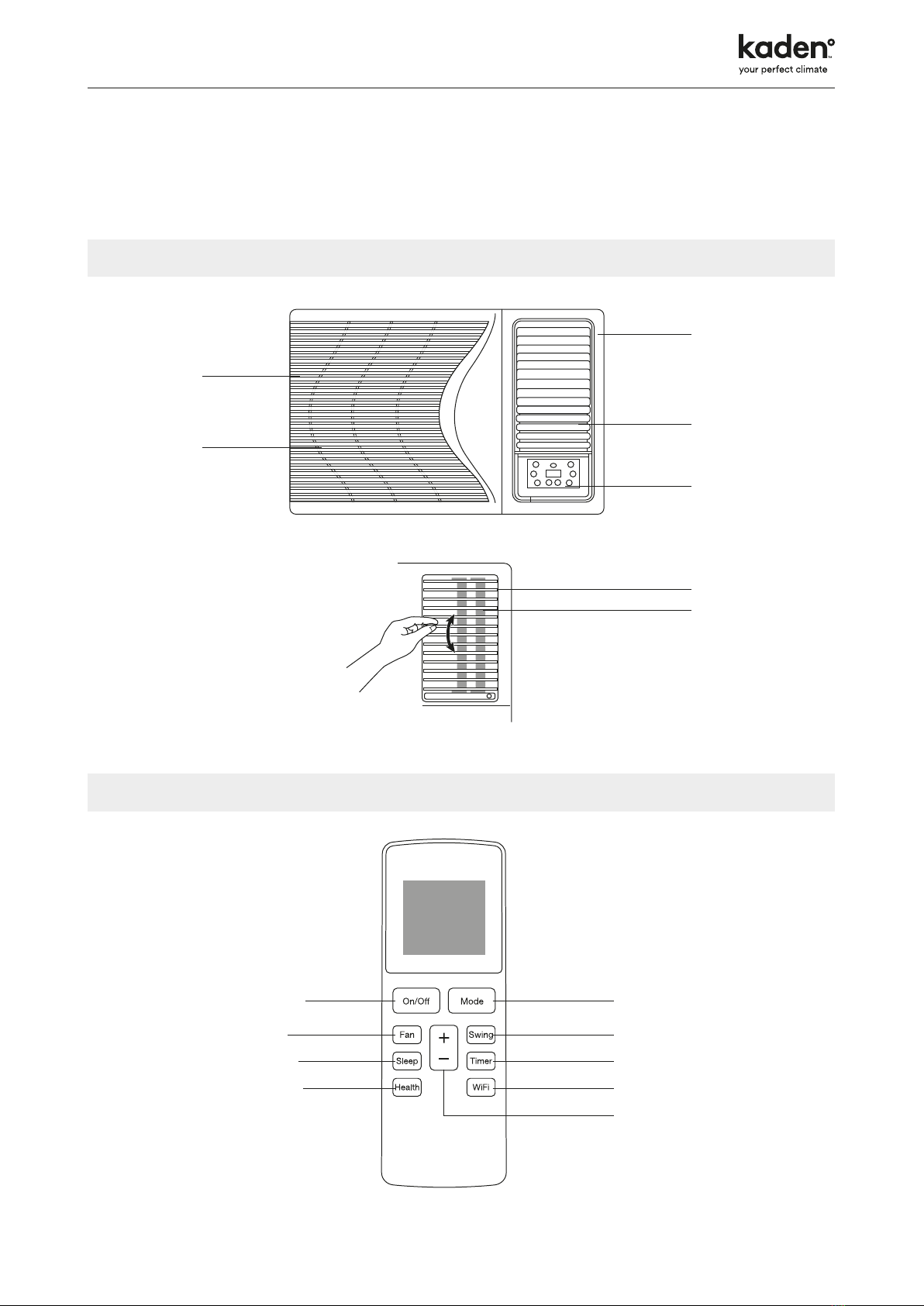

Remote control operation procedure

1. On/O button

Press this button to turn on the unit. Press this button again to

turn off the unit.

2. Mode button

Press this button to switch between the different operating

modes. The corresponding indicator will appear on.

Auto: Under this mode, the unit will operate automatically

according to ex-factory setting. In this case, set temperature

cannot be adjusted.

Cool: Under this mode, the unit will operate under cooling

mode. Cooling indicator will be on. Press Fan Speed button to

adjust the fan speed.

Dry: Under this mode, the unit runs in low fan speed for

dehumidification and the corresponding indicator will be on;

under dry mode, the fan speed cannot be adjusted.

Fan only: Under this mode, the unit will not cool or heat, only

blow air. Fan indicator will be on. Press Fan Speed button to

adjust the fan speed.

Heat: Under this mode, the unit operates under heating mode.

Press Fan Speed button to adjust the fan speed.

3. +/– button

Pressing +or –button once will increase or decrease set

temperature by 1°C (or °F).

Hold +or –button for two seconds, set temperature on remote

controller will change more quickly.

Release the button after your required set temperature

is reached.

Under timer setting status, after each pressing of +or –button,

time will increase or decrease 0.5 hours. Hold +or –button,

after two seconds the time shown on the display will quickly

change. Loosen the button until the time is reached to your

set time.

4. Swing button

Press this button to turn swing on or off.

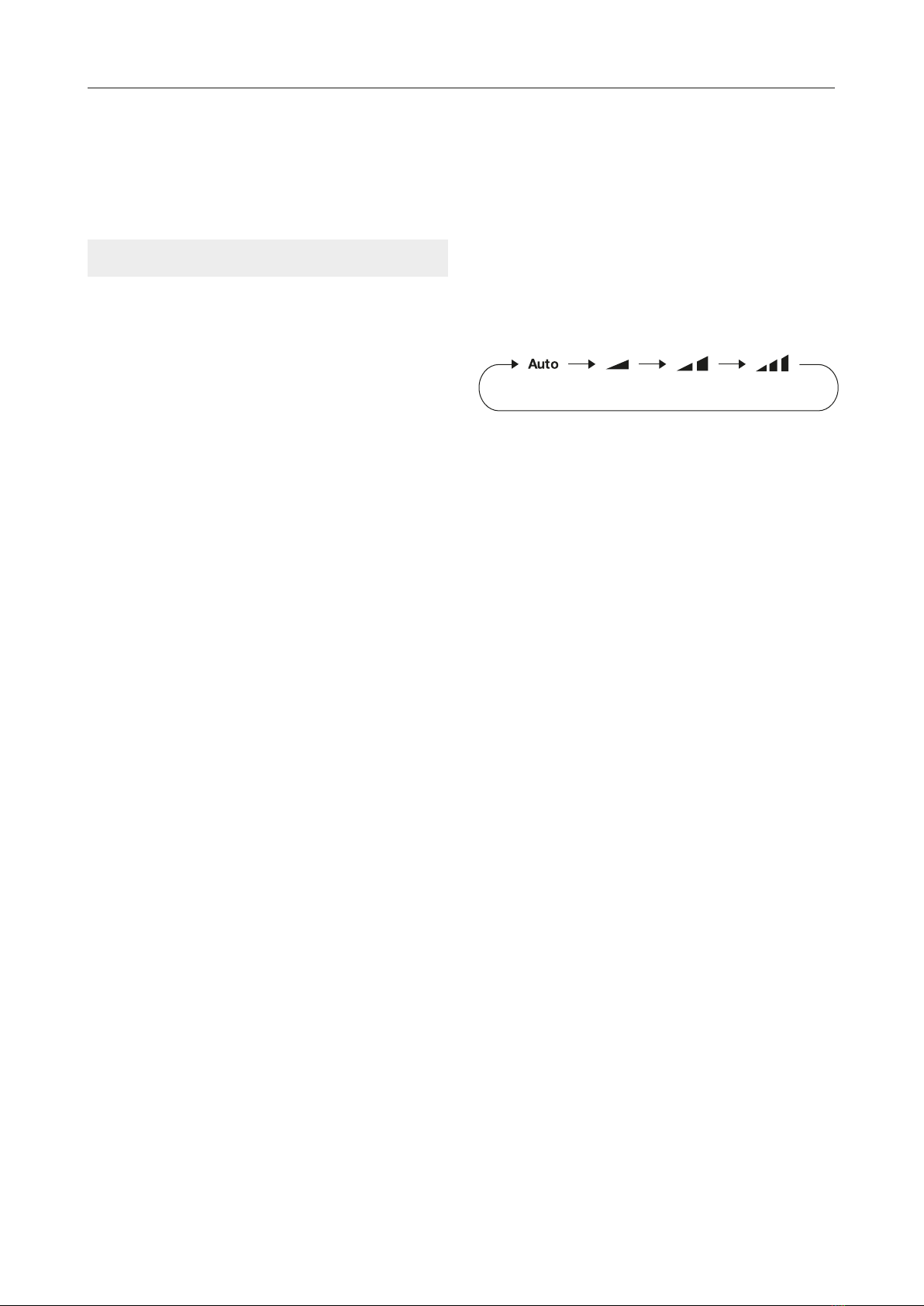

5. Fan button

This button is used for setting Fan Speed in the sequence that

goes from Auto, through the speed settings then back to Auto.

NOTE: There are three speeds for the fan speed of this model.

6. Sleep button

Press this button to go into the Sleep operation mode. Press it

again to cancel this function.

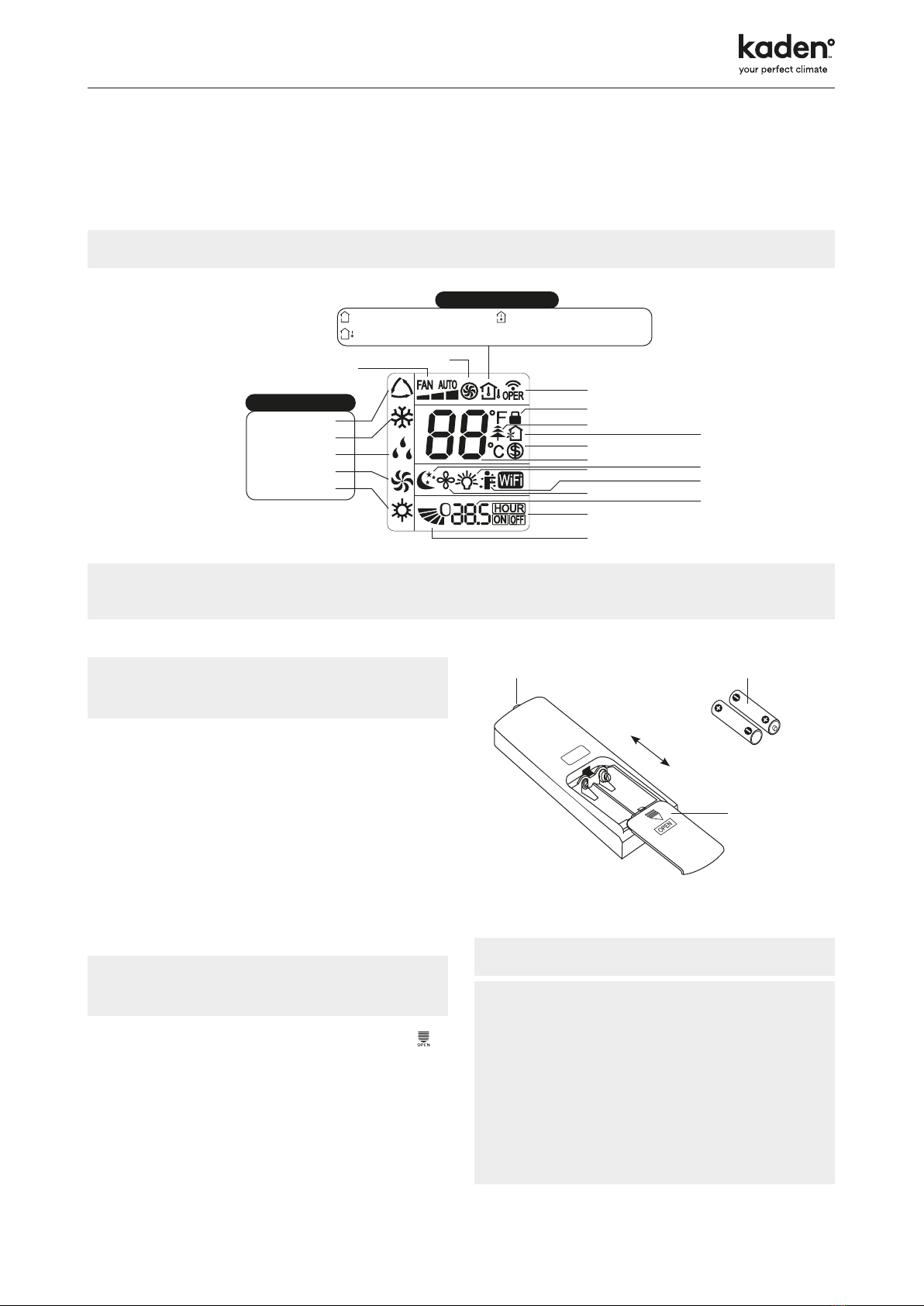

7. Timer button

Under On status, press this button to set timer Off.

Under Off status, press this button to set timer On.

Press this button once and the characters of Hour On (Off) will

flash to be displayed. Meanwhile, press +button or –button

to adjust timer setting (time will change more quickly if holding

+or –button). Time setting range is 0.5 to 24 hours. Press

this button again to confirm timer setting and the characters of

Hour On (Off) will stop flashing.

If the characters are flashing but you haven’t pressed the Timer

button, timer setting status will quit after five seconds. If timer is

confirmed, press this button again to cancel timer.

8. Health button

The KW range does not come with the additional health

feature. The standard remote included with the KW range

includes the health button, however this button will not

activate a health feature mode.

9. Wi-Fi button

Press Wi-Fi button to turn on Wi-Fi function, Wi-Fi icon will be

displayed on the remote controller.

Hold Wi-Fi button for five seconds to turn off Wi-Fi function

and Wi-Fi icon will disappear. Under off status, press Mode

and Wi-Fi buttons simultaneously for one second and the Wi-Fi

module will restore factory settings.

Auto Speed 1 Speed 3Speed 2