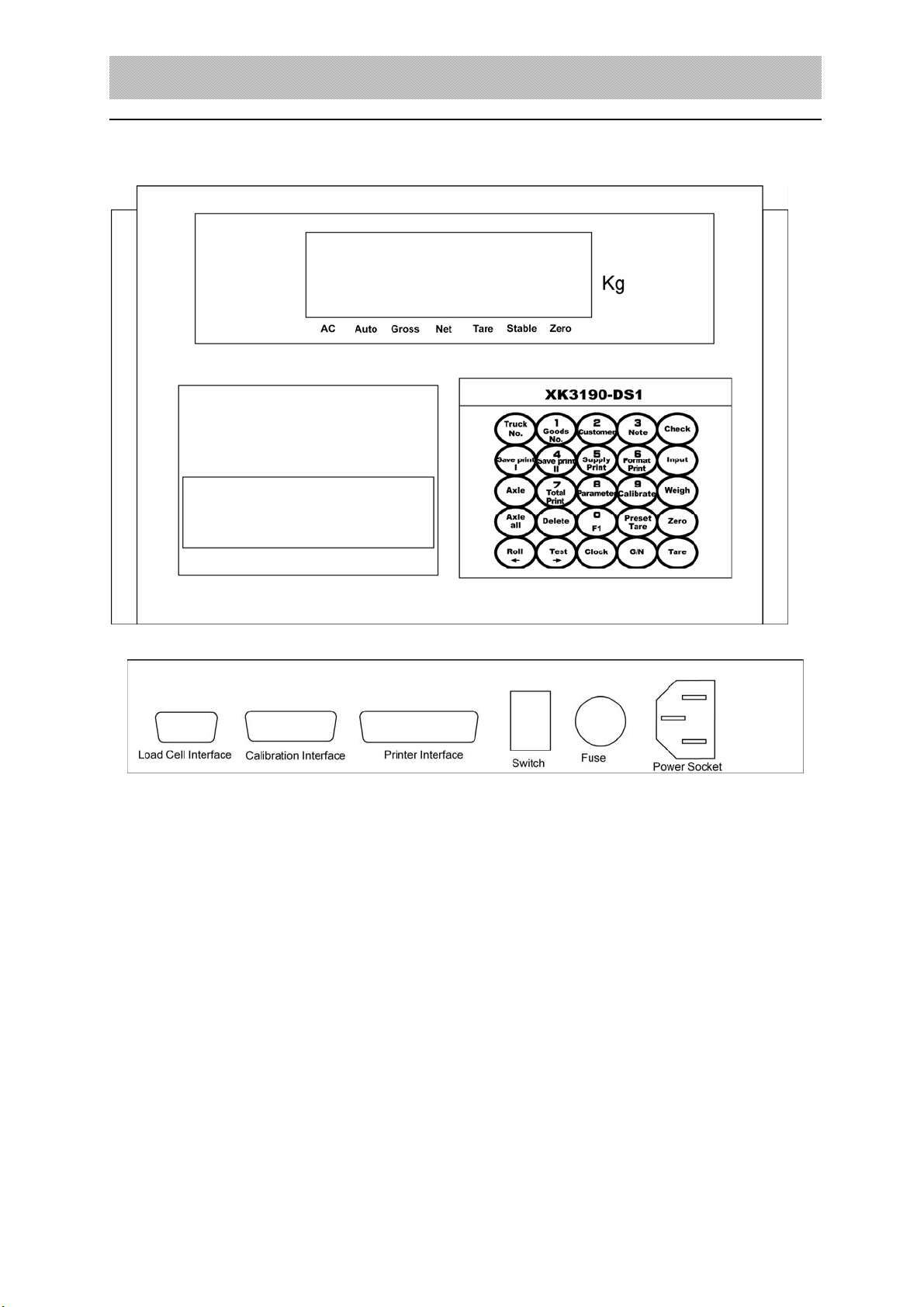

XK3190-DS1

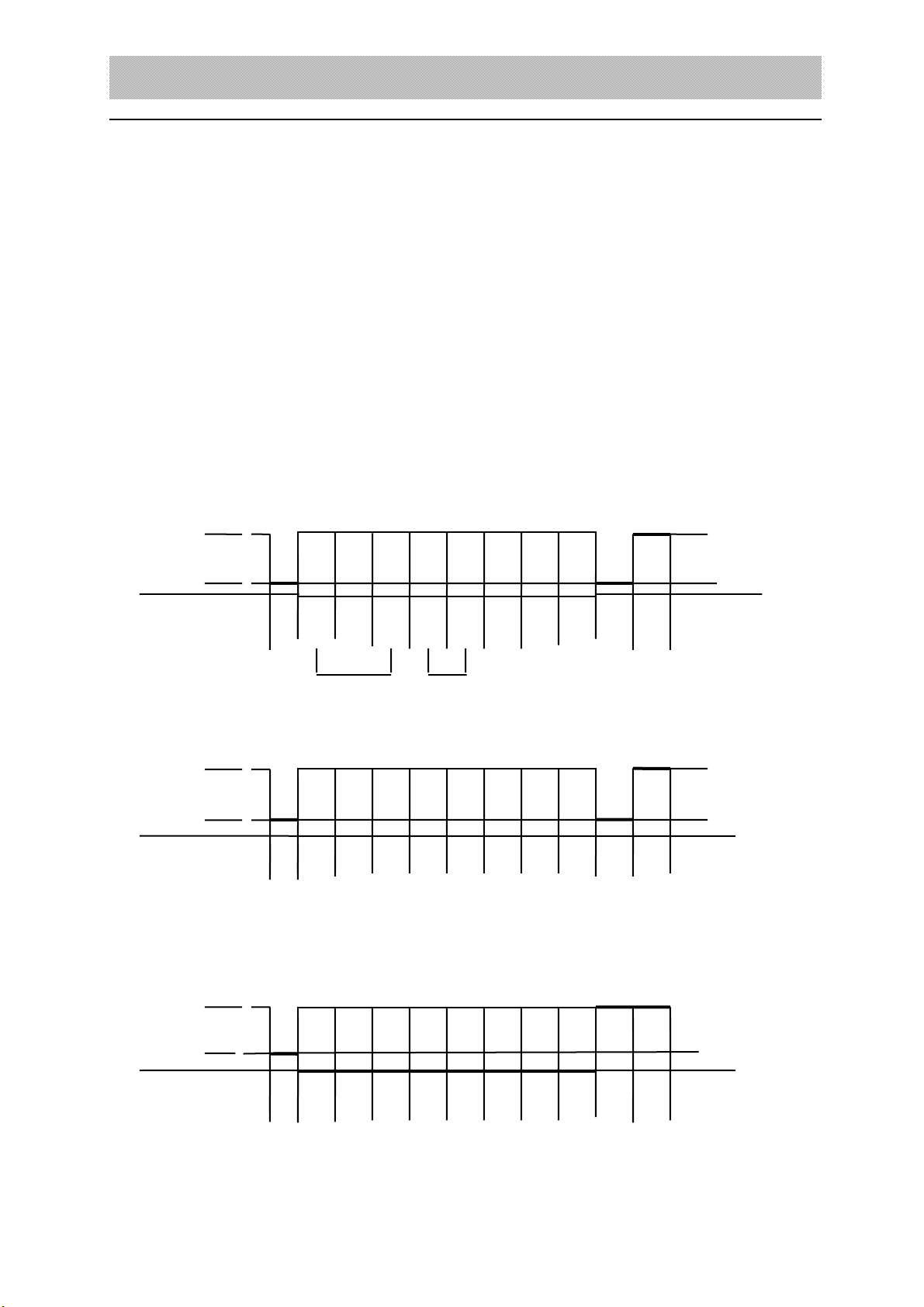

5

First frame:signal bit is 0

X :D0、D1、D2 – are decimal point ( 0~4 )

Y :D3 — weight symbol( 1-negative、0-positive )

D4 — spare use

G 18~G16:weight data

Second frame:signal bit is0

G15~G8:are weight data

Third frame:signal bit is 1

G7~G0 :weight data

G0~G18:from low to high, 19 binary code composed of weight(net weighit)

5. connect to serial communication interface

▲ !please connect the communication wire to the computer correctly. Damage might be caused

to indicator interface ,computer interface or indicator, computer and relevant devices if they are

connected incorrectly.

▲ !only the person who has the ability of program or relevant computer skill are entitled

to operate the communication with computer, it is necessary to have a professional

person to instruct. Unprofessional person please do not operate to avoid any mistakes.

▲ ! communication interface is 15 pin RS232 connector( same with scoreboard interface),

the definition of pin6,7,8(RS232) or pin 1,2,3,4(RS232) are indicated in the following

2-7

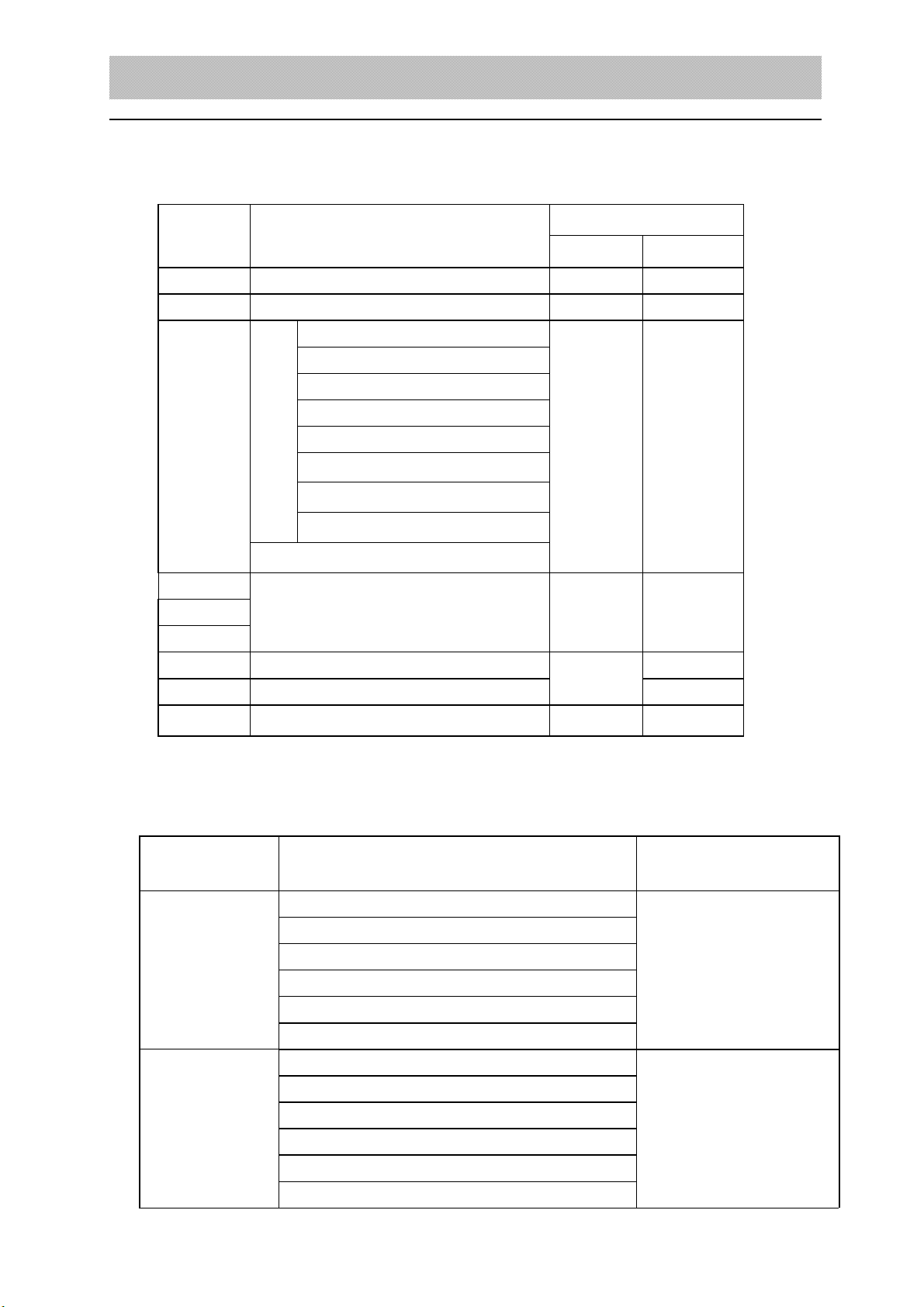

(RS422 optional)RS232C communication signal

+TX -TX +R -R RXD TXD signal position

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15

+OUT -OUT

Scoreboard signal output TX(scoreboard RS232output)

(2-7) communication interface definition

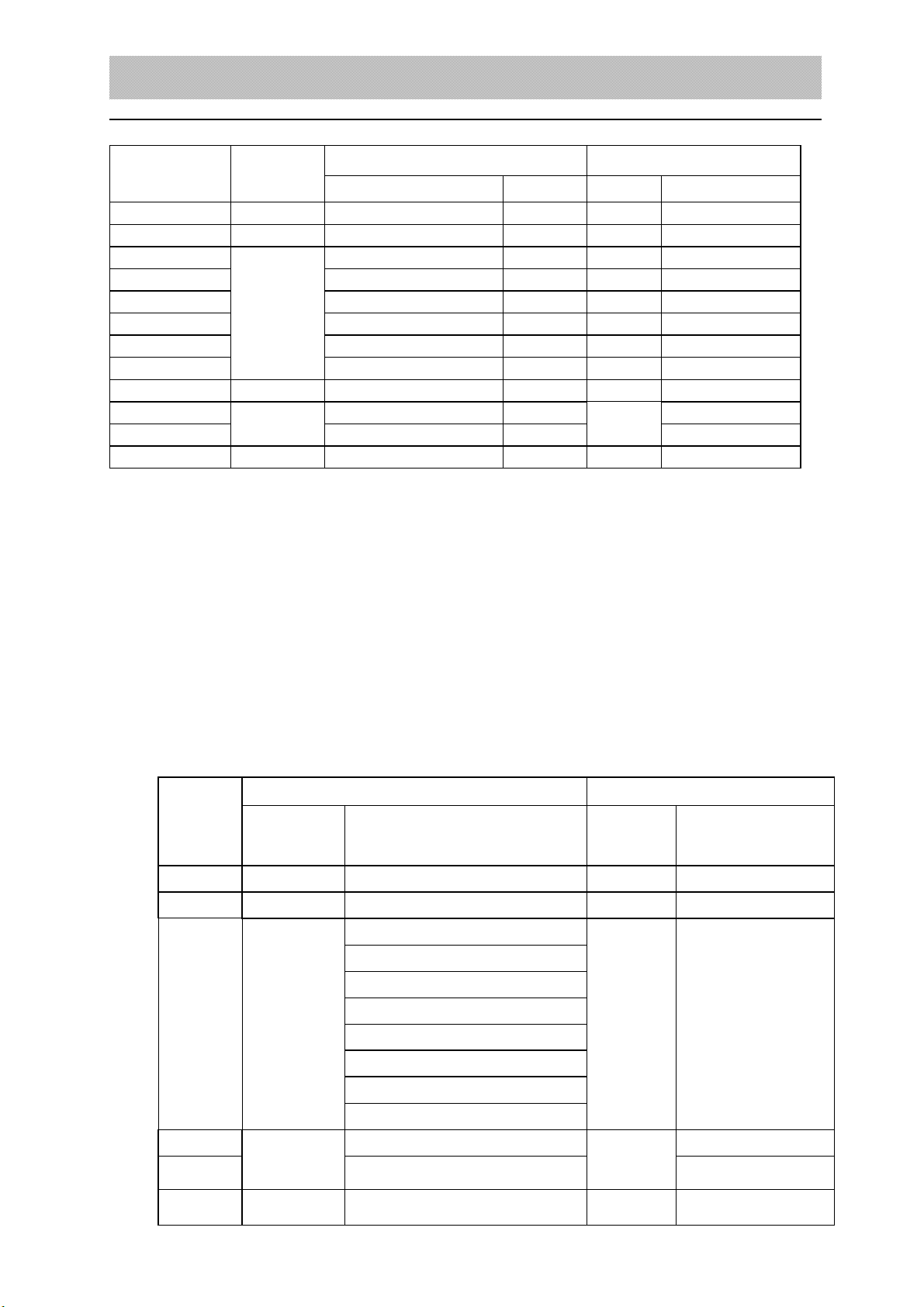

1. serial communication instruction:

serial data frame is :n,8,1: 8 data bit, 1 stop bit, no check bit;XK3190-DS1 serial

communication has continuous communication method and command communication method,

serial method has 3 types; through TF parameter (please refer to the chapter 3 for the detail).

Here we just instruct 2 situations when the TF=0,1

(1). Continuous method(TF=0):

The transmission data is the displayed data of the indicator(gross weight). Each data frame

are composed of 12 group data.

The format is as following 2-1: