Techni

ca

l Information DCD90-

180

Lift

Mas

ts

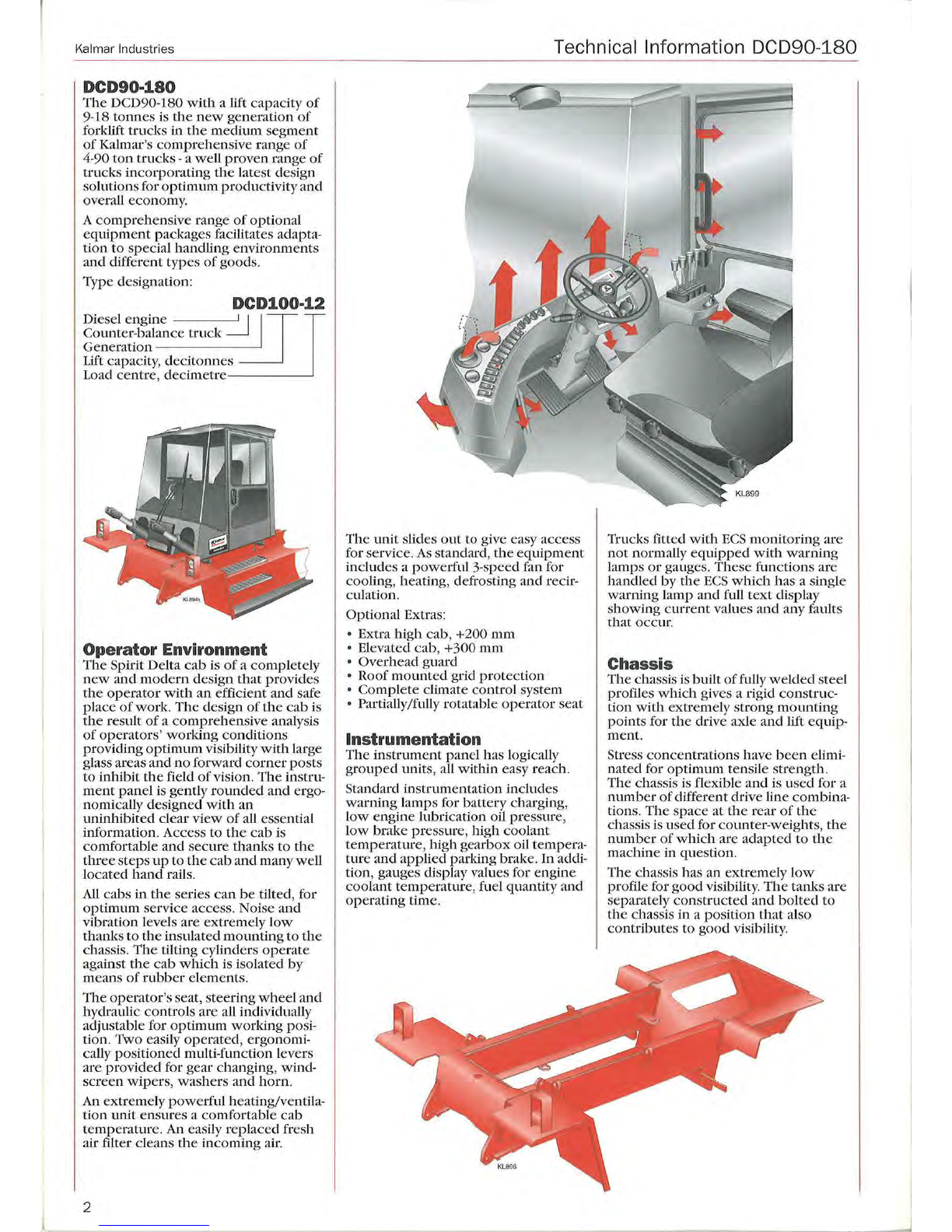

All masts, b

ot

h dupl

ex

a

nd

t

ri

p l

ex

, are

constr

u

cted

on

th e "free visibility prin-

cip

l

e"

and

can

be

su

pp

li

ed

wi

th

the

area

steered

free

-

Lift

system

wh

ic

h, in

term

s of fu n

ctio

n, is

ex

tr

eme

ly re

li

able

a

nd

sec

ur

e.

The

rob

ust mast profil

es

are

of

high

te

ns

il

e st

ee

l, di mensioned fo r minimal

ob

st

ru

ctio n

of

the fie

ld

of

vision a

nd

long

se

rvi

ce

life. Th e lift

cy

linders

are

pos

ition

ed

in

th

e "

dea

d " angl

es

of the

mas

t.

All mast wh

ee

ls are ha rdened a

nd

fitted w ith high quality bearings.

As

sta

nd

ard,

tr

ucks are fitted w ith

th

e

d up l

ex

fr

ee

visibility m

as

t.

Opt

i

ona

l

ex

tr

as:

• Dup l

ex

free visib

ili

ty m

ast

w ith

free-

li

ft

• Trip l

ex

fr

ee

visibili

ty

mast w i

th

free-lift

Duplex free

visibility mast

Dupl

ex

free

visibility

mast

with

free·

lift

Triplex free

visibili

ty

mast

wi

th

free·

lift

90·136,

two free·

lift

cylinders

(150-180, one

ce

ntr

al free-l

ift

cylinder)

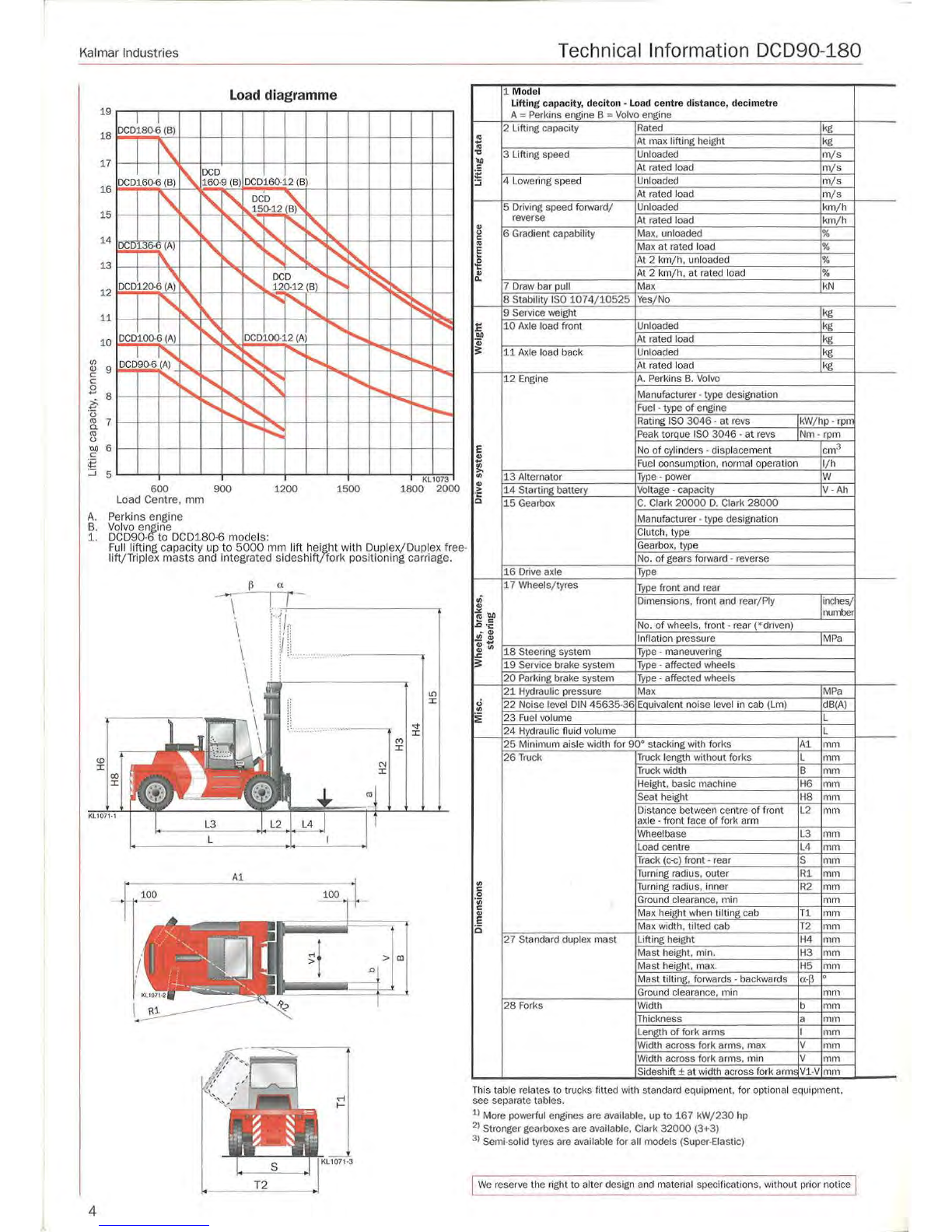

Fork Carriages

A number

of

different

mo

dels

of

fork

carr

iages are avai

la

ble, a

ll

of

them

wit

h

exce

ll

ent th

roug

h-vision. The stand

ar

d

mode

l has manua

ll

y

moveab

le fo

rk

s.

Howev

er,

the

majority

of

trucks are

sup pli

ed

with hydraulic side-shift and

fork

posi

tioning.

Op tional extras:

• Fork

pos

itionin

g/s

ide-s

hi

ft

• Fork

pos

itio nin

g/s

id

e-s

hi

ft wi

th

leve

ll

ing

• Fork

pos

itionin

g/s

ide-shift w ith

ce

ntre leve

ll

ing

• Side-shi ft ca

rri

age

• Fork shaft system

• Addi tional types

of

clamp

attac

hm

e

nt

s

• Coil rams for

stee

l

han

dling

Side-

shift

carriage

F

orks

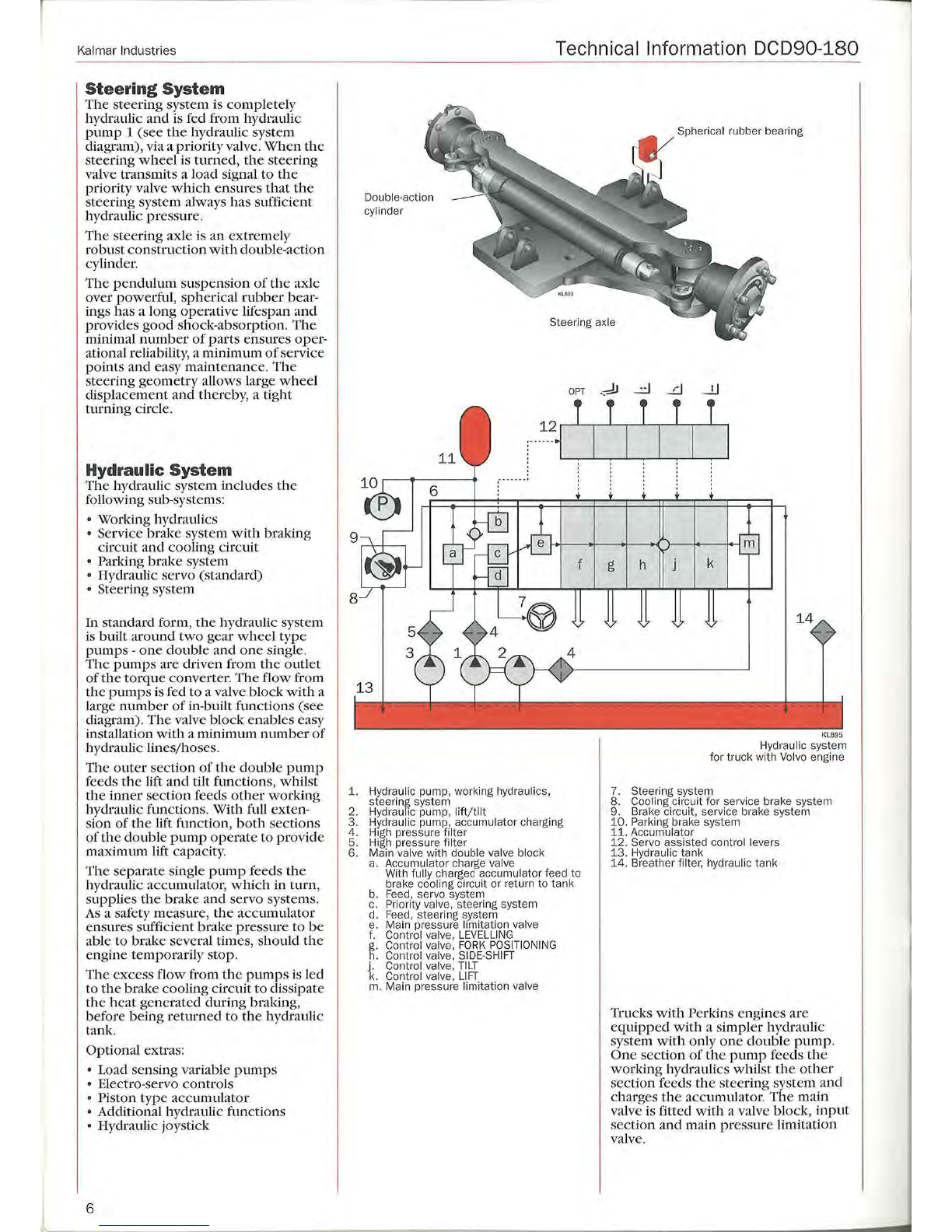

The forks

are

one-pi

ece

for

ged

in

hig h

tens

il

e

stee

l.

The standard

fi

tti ng is

over

h

oo

ks o n the fork

ca

rriage, whilst

hy

dr

auli

ca

ll

y

co

ntr

o

ll

ed forks are fitted

ove

r ro

ll

ers

runnin

g on bearings -fo

ur

up

pe r

ro

ll

ers a

nd

two

l

ower

su

ppo

rt

fo r

eac

h

fo

rk.

For

ease

of

changing

be

t

wee

n

fo

rks

an

d

ot

h

er

a

tt

ac

hments, a fork shaft system

is available , w h

ere

the

fo

rks

are

mo

un

te

d on a separate fo rk holder.

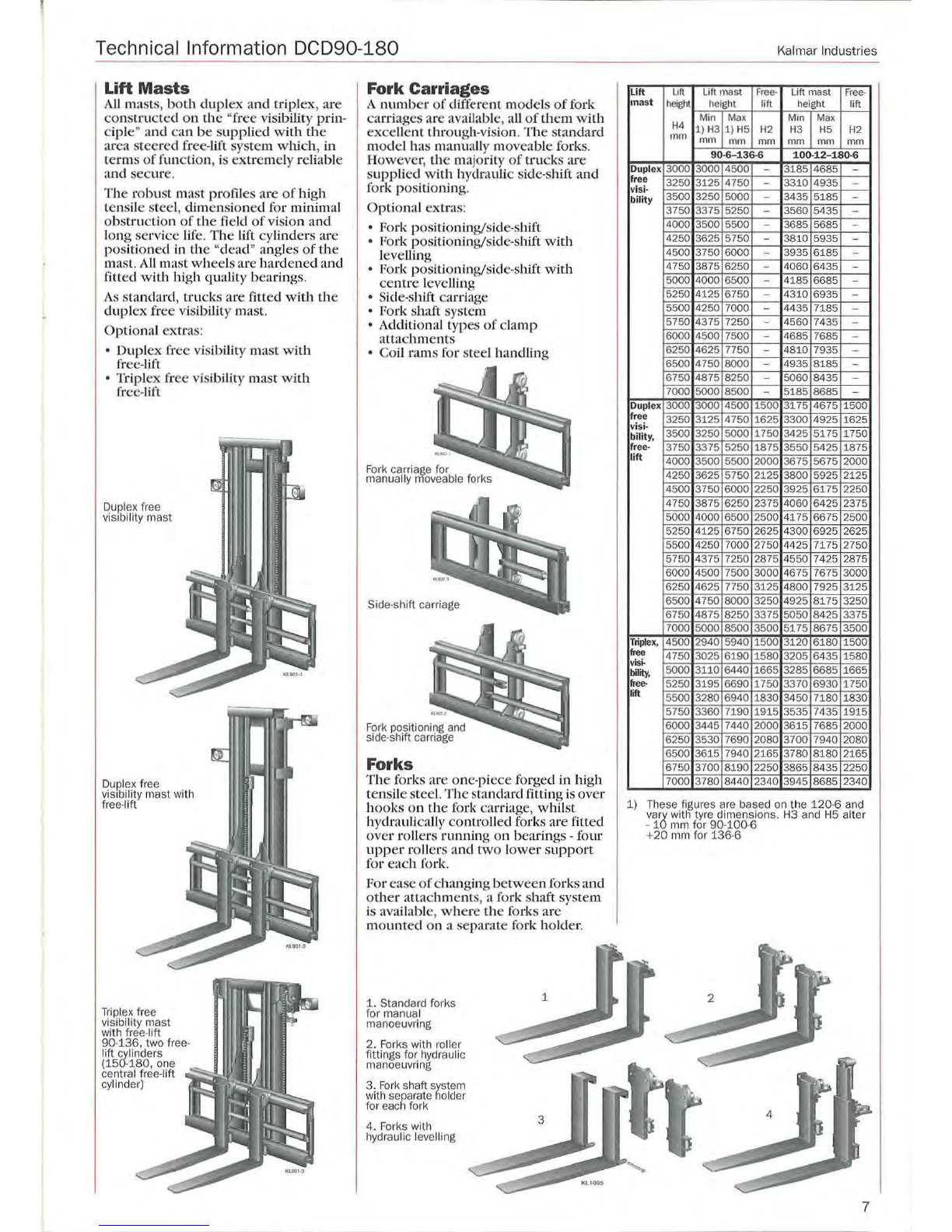

1.

Standard forks

for manual

manoeuvring

2. Forks with roller

fittings for h

yd

raulic

manoeuvring

3.

Fo

rk shaft system

with separate

ho

lder

for each fork

4.

Forks with

hyd

ra

ulic levelling 3

Kalmar Industries

Lift

Uft

Lift mast

Free

· Lift mast

Free-

m

as

t

heigl'lt

heig

ht lift

height

lift

Mi

n

Max

Min

Max

H4

1)

H3

1)

H5

H2

H3 H5

H2

mm

mm mm mm mm

mm mm

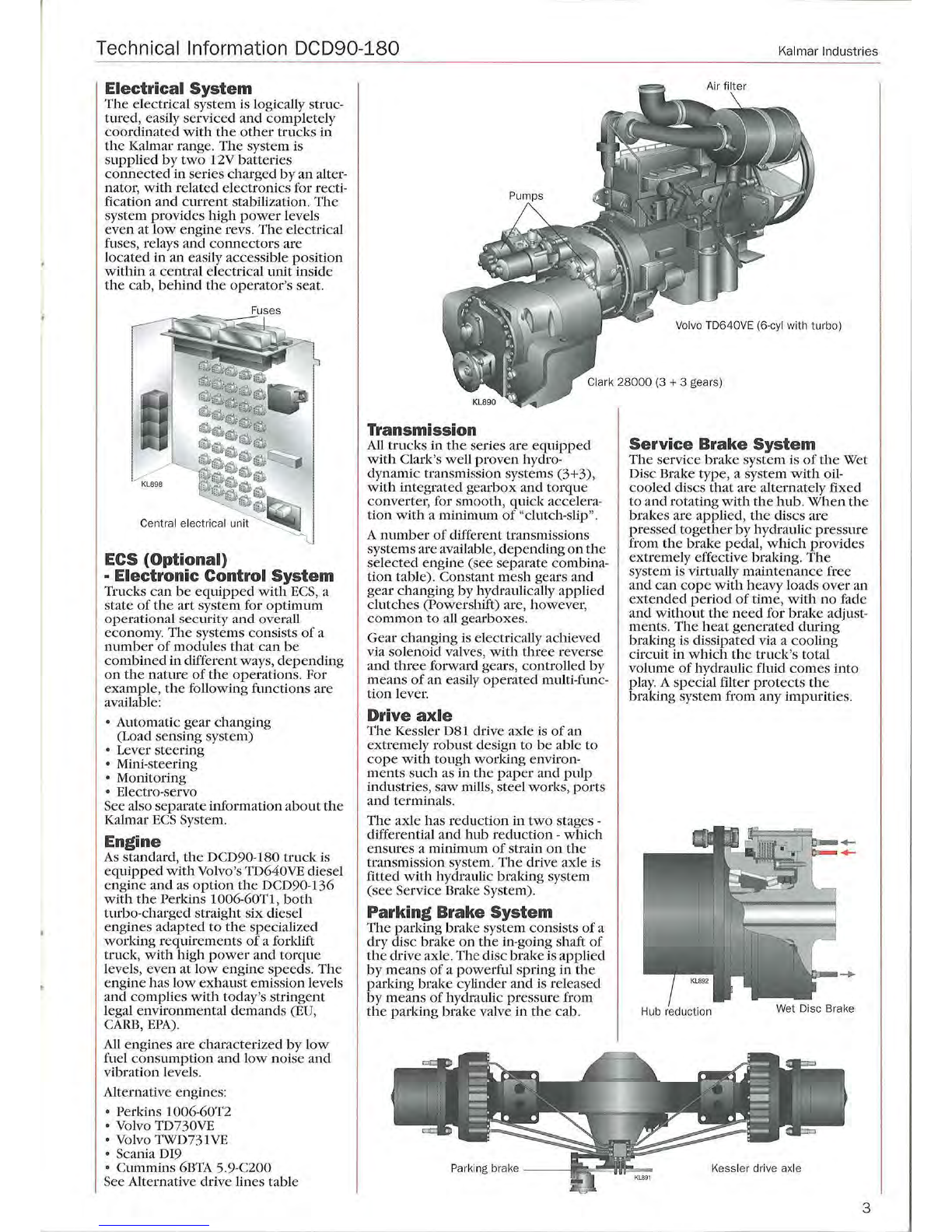

90

·6-

136

-6

100-1 2-

180

-6

Dupl

ex

3000 3000 4500 -3185 4685 -

fr

ee

3250 3125 4750 -3310 4935 -

vis

i-

bility 3500 3250 5000 -3435 5185 -

3750 3375 5250 -3560 5435 -

4000 3500 5500 -3685 5685 -

4250 3625 5750 -3810 5935 -

4500 3750 6000 -3935 6185 -

4750 3875 6250 -4060 6435 -

5000 4000 6500 -4185 6685 -

5250 4125 6750 -4310 6935 -

5500 4250 7000 -4435 7185 -

5750 4375 7250 -4560 7435 -

6000 4500 7500 -4685 7685 -

6250 4625 7750 -4810 7935 -

6500 4750 8000 -4935

8185

-

6750 4875 8250 -5060

8435

-

7000 5000 8500 -5185

8685

-

Dup

l

ex

3000 3000 4500 1500 3175 4675 1500

fr

ee

3250 3125 4750 1625 3300 4925 1625

vi

si-

bility, 3500 3250 5000 1750 3425 5175 1750

fr

ee-

3750 3375 5250 1875 3550 5425 1875

lift

4000 3500 5500 2000 3675 5675 2000

4250 3625 5750 2125 3800 5925 2125

4500 3750 6000 2250 3925 6175 2250

4750 3875 6250 2375 4060 6425 2375

5000 4000 6500 2500 4175 6675 2500

5250 4125 6750 2625 4300 6925 2625

5500 4250 7000 2750 4425 7175 2750

5750 4375 7250 2875 4550 7425 2875

6000 4500 7500 3000 4675 7675 3000

6250 4625 7750 3125 4800 7925 3125

6500 4750

8000

3250 4925

8175

3250

6750 4875

8250

3375 5050

8425

3375

7000 5000

8500

3500 5175

86

75 3500

Tripl

ex

, 4500 2940 5940 1500 3120

6180

1500

free 4750 3025 6190 1580 3205

6435

1580

vis~

bi

l

ity

, 5000 3110 6440 1665 3285

6685

1665

fr

ee-

5250 3195 6690 1750 3370

6930

1750

lift 55

00

3280 6940 1830 3450 7180 1830

5750 3360 7190 1915 3535 7435 1915

6000 3445 7440 2000 3615 7685 2000

6250 3530 7690 2080 3700 7940 2080

6500 3615 7940 21

65

3780

8180

2165

6750 3700 8190 2250 3865

8435

2250

7000 3780 8

44

0

23

40 3945

8685

2340

1)

These figures are based on

th

e 1

20·6

and

va~

wi

th

tyre dimensions. H3 and H5 alter

-1 mm for

90-100

·6

+20

mm for 1

36-6

:!"

Ia

~

I

~):1,

2

........

~

f

•

~

..

~

.......

·t:

~

,

~

4 l i

~

~

l

""'

~

......

~

7