3

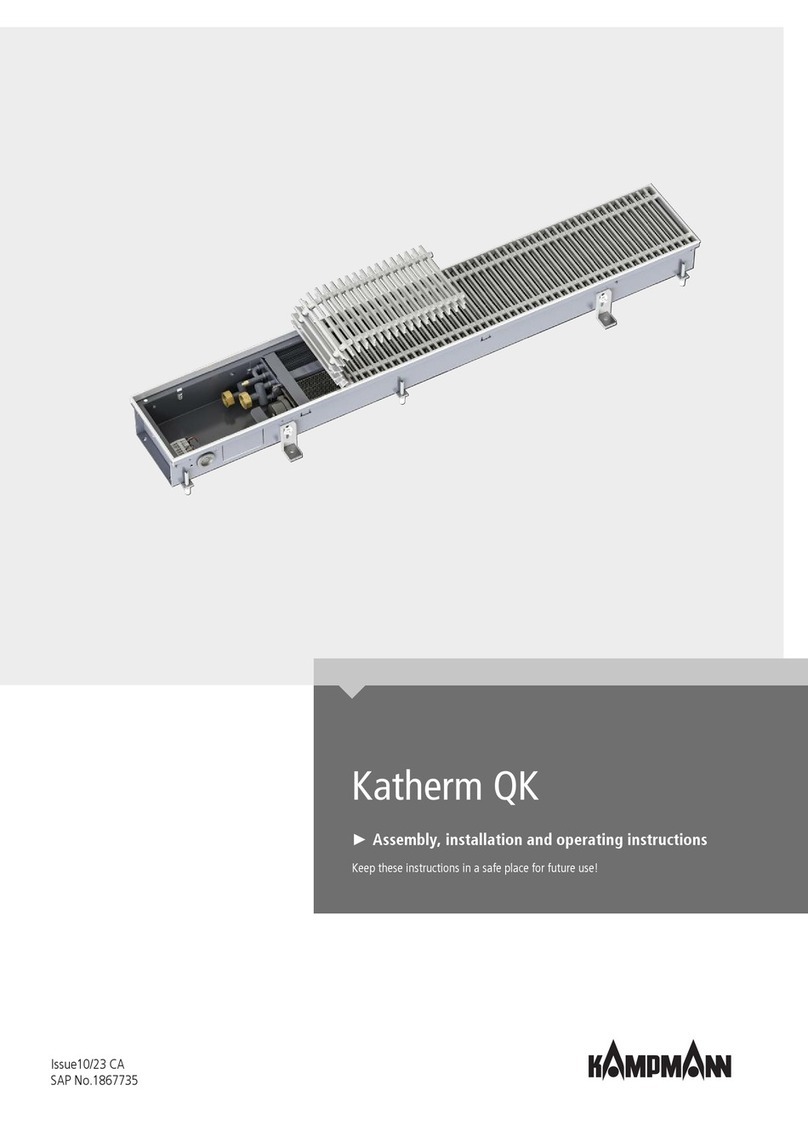

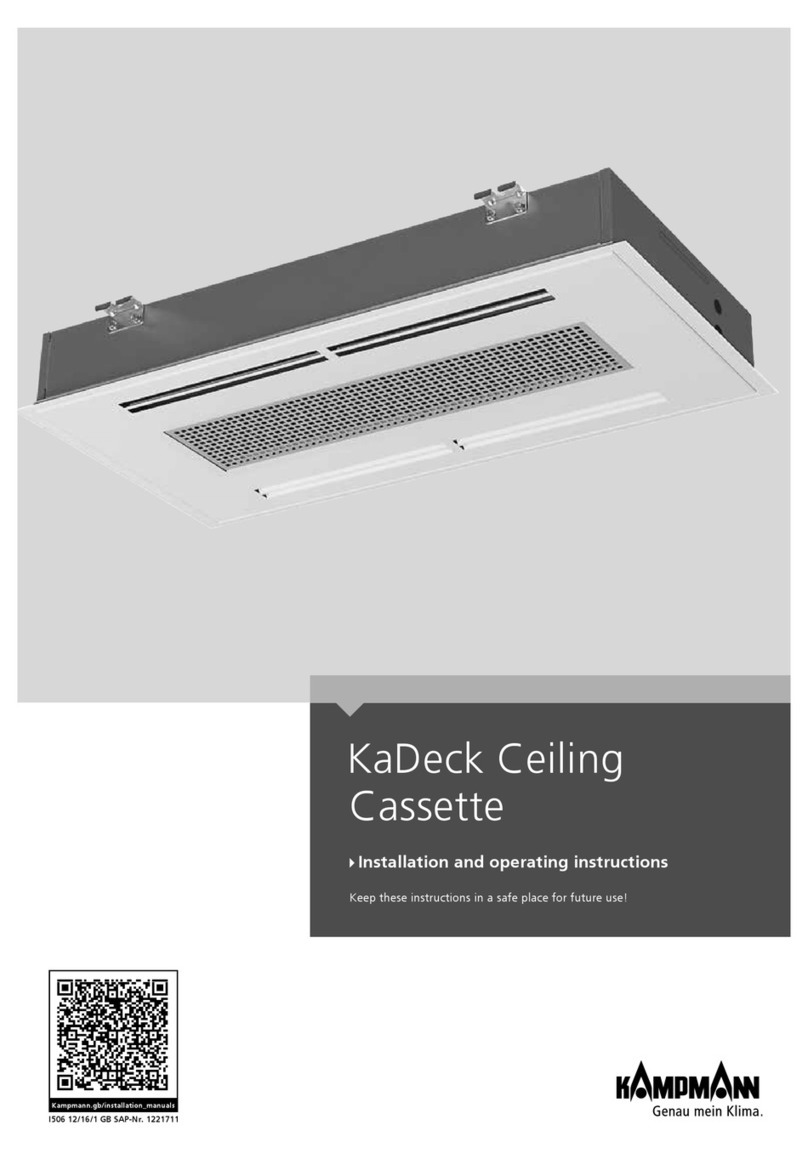

Ultra 1.54

Comfortable indoor climate in high-end interiors

Installation and operating instructions

Key to symbols:

Caution! Danger!

Non-compliance with this

information can lead to

serious personal injuries

or damage to property.

Danger from

electrocution!

Non-compliance with this

information can lead to

serious personal injuries

or damage to property by

electrocution.

Carefully read these

instructions in full prior

to any assembly and

installation work!

Anyone involved

with the installation,

commissioning and use

of this product is obliged

to pass these instructions

on to tradespeople who

are involved at the same

time or subsequently, as

well as to end users or

operators. Retain these

instructions until final

decommissioning!

We reserve the right

to make content or

design-related changes

without prior notice!

Contents

1. Intended use.............................................................................. 5

1.1 Limits of operation and use.................................................... 6

1.2 Limits of use for cooling......................................................... 7

1.3 Condensation pump .............................................................. 7

1.3.1 Connecting the condensation pump ................................... 8

1.3.2 Limits of use of the condensation pump ............................. 8

2. Safety information.................................................................... 9

3. Scope of delivery....................................................................... 10

4. Transport and storage .............................................................. 11

5. Technical data ............................................................................ 11

6. Installation................................................................................. 12

6.1 Installation of the Ultra .......................................................... 12

6.2 Filter assembly........................................................................ 14

6.3 Installation of the intake crown.............................................. 14

7. Waterside connection ............................................................... 15

8. Factory-fitted accessories ......................................................... 15

9. Installation of condensation connection

(with Ultra for cooling)............................................................. 16

9.1 Routing the condensation lines .............................................. 16

9.2 Connecting the condensate pump ......................................... 16

9.2.1 Ultra without fitted KaControl module, recirculation air ...... 16

9.2.2 Ultra with fitted KaControl module, recirculation air ........... 17

9.3 Connection work ................................................................... 18

9.4 Commissioning and functional testing of condensation pump 18

9.5 Warning information/Technical data on condensation pump .. 18

10. Electrical wiring......................................................................... 19

10.1 Safety information ............................................................... 19

10.2 Motor protection ................................................................ 20

10.2.1 AC fans ........................................................................... 20

10.2.2 EC fans ............................................................................ 21

10.3 Electrical wiring.................................................................... 21

10.3.1 Three-phase motors .......................................................... 24

10.3.2 AC single-phase motors .................................................... 26

10.3.2.1 Single-phase controller................................................... 26

10.3.2.2 Continuously variable power module type ...16 V .......... 27

10.3.2.3 KaControl recirculation air module type ...16C1............. 29

10.3.3 EC single-phase motor ...................................................... 31

10.3.3.1 Control with 0-10 VDC type ...33/34 ............................ 32

10.3.3.2 KaControl recirculation air module type ...33C1/34C1 ... 33