Make a “Z” bend in the control wire and install

the servo arm. Adjust as necessary for proper

operation. A slight bend in the control wire may be

necessary for smooth operation.

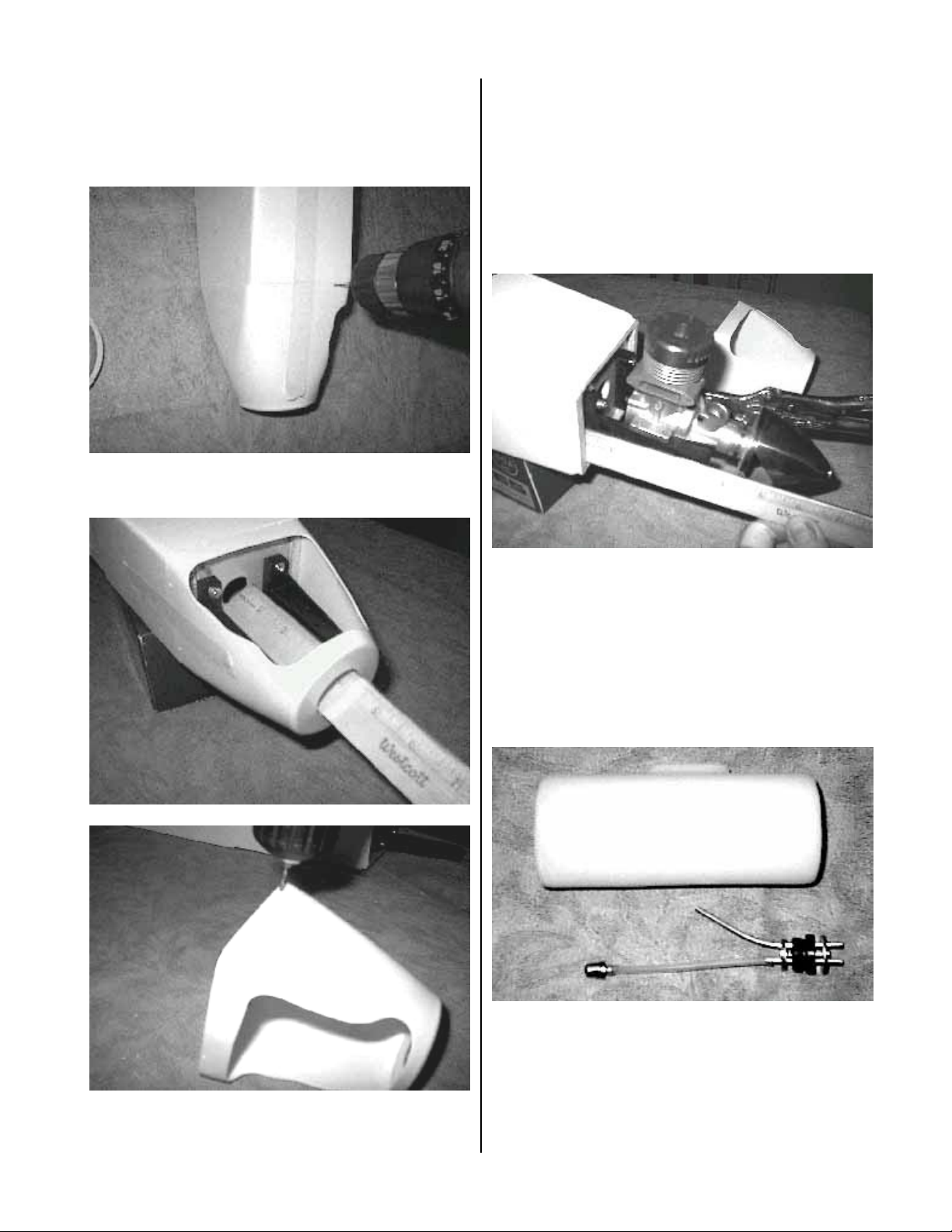

Locate the two control rods. The one for the

elevator has two holes in one end, one hole in the

other. The one for the rudder has one hole in each

end. Make a 90-degree bend in three of the control

wires 6 ½-inches from the threaded end. Cut the

wires just past the bend leaving 1/8-inch. Press

two of these wires into one end of the elevator

control rod squeeze gently with pliers then wrap

tightly with thread. Soak the thread with CA.

Repeat this process in one end of the rudder

control rod. Bend one more wire 6 ¼-inches and

cut in the same manner as before. Install this wire

in the other end of the elevator control rod. For the

other end of the rudder control rod make the wire

10 inches. The two wires on the elevator control

rod now need to be spread apart. Make two equal

bends, one in each wire 3/8-inch from the end of

the wood rod. Bend the wire until the threaded

ends are 2 ¾-inches apart.

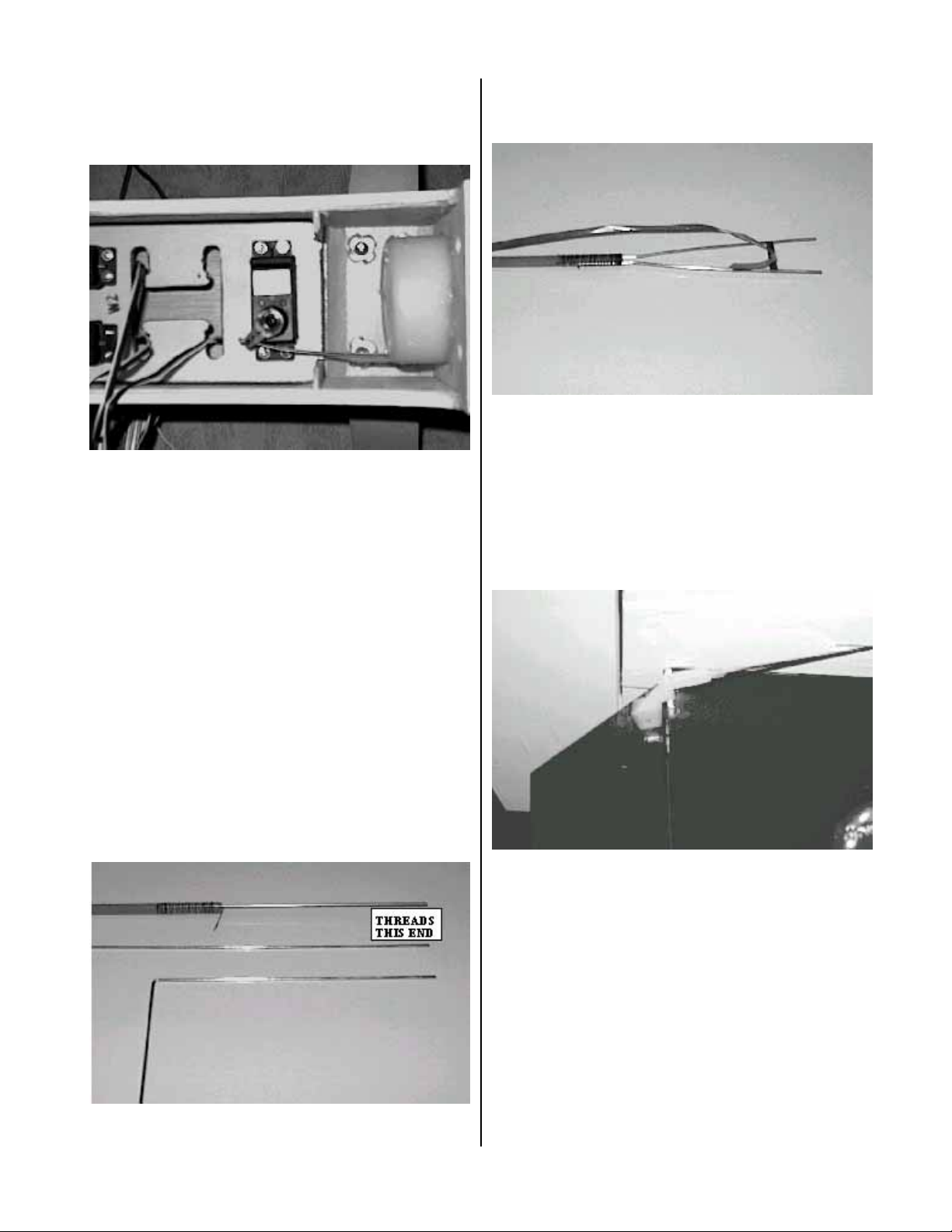

To insert the control rod into the fuselage, tie a

string around the fork and pull the ends together as

shown. Slide the control rod into the fuselage, line

the wires up with the fuselage slots and pull the

string to release the wires through the slots.

Screw a clevis on each wire of the elevator till

about 1/8-inch of thread remains exposed. Place a

control horn in the clevis and with the control

surface straight locate the control horn so the

adjustment holes are inline with the leading edge

of the control surface. Install the control horn in

this location using the provided screws and

backing plates. Repeat this procedure for the

rudder

Screw a clevis on the servo end of the elevator

control rod. With the servos centered and the

control surfaces straight adjust the clevis and

install on the servo arm. Mark the rudder wire and

install in the same manner using a “Z” bend.

10