9 of 32 © 2003 D 362e - 06/03

Section C1

Boiler Supply

Sensor

Section C2

Boiler Return

Sensor

Section C: Boiler Operation

Section C1: Boiler Supply Sen or

Section C3

No Boiler

Sensor

BOILER SENSOR ON THE SUPPLY (Boil SENS = SUP)

The boiler sensor can be located on the boiler supply if the 362e is the only control that

is operating the boiler. When in the supply mode, the control determines the required

operating temperature for the boiler supply and cycles the Boiler contact in order

to maintain the correct boiler supply water temperature. If this mode of operation is

selected, the boiler pump should either operate continuously or be operated in parallel

with the Mixing Pump contact (Mix Pmp). The boiler pump should not be operated by

the operating aquastat as this may lead to improper cycling of the boiler because of

inconsistent flow past the boiler supply sensor. This mode of operation only works if

the Boil SENS item is set to SUP.

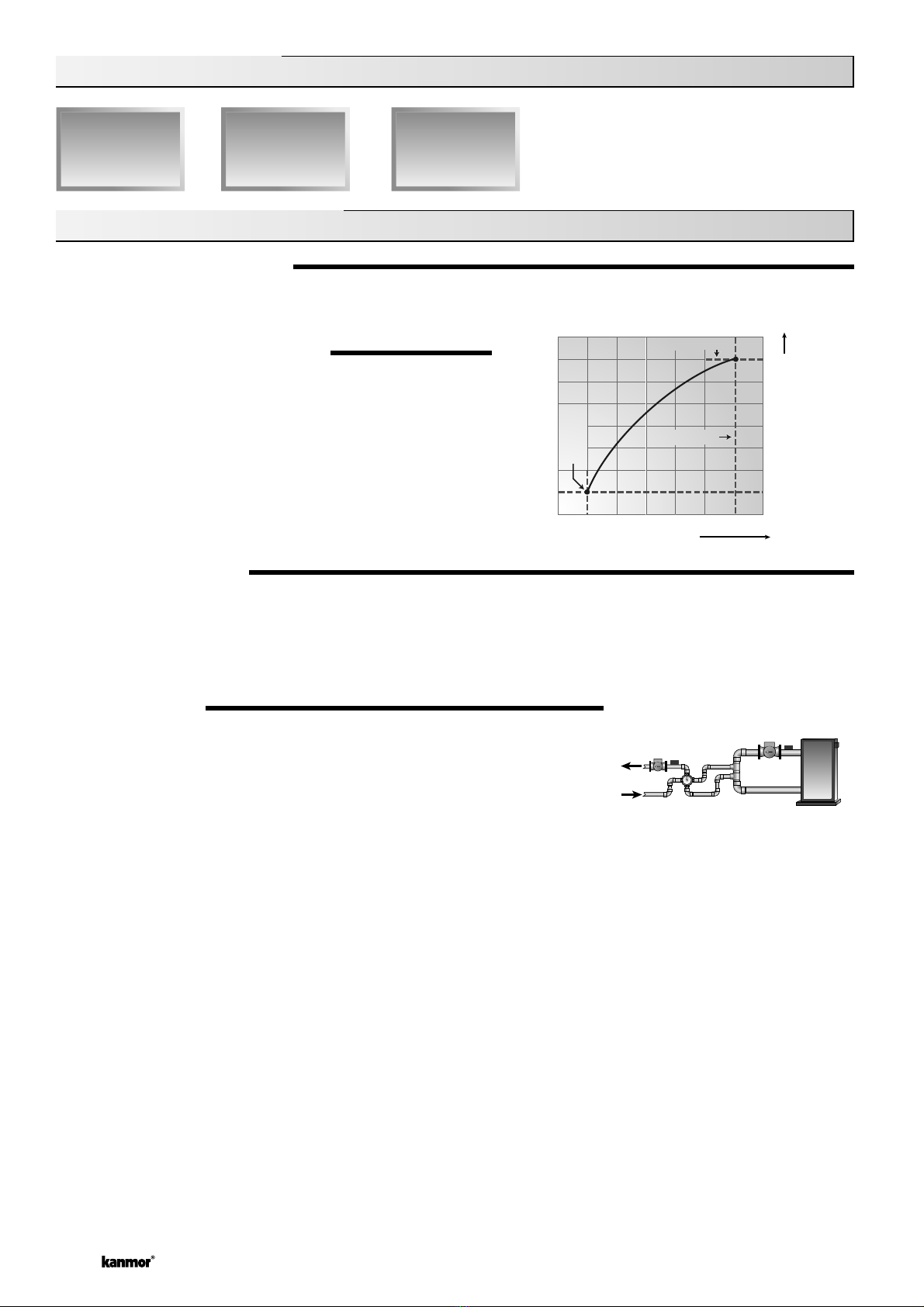

BOILER TARGET TEMPERATURE (Boil TRG)

The Boiler Target temperature is determined by the operation of the mixing de ice. The control uses a method called Boiler

Load Reset in order to determine the required boiler supply water temperature. The control operates the boiler at a supply

temperature that is sufficient to satisfy the requirements of the mixing de ice. If the boiler supply water temperature is not

sufficient, the control increases the boiler target temperature. If the boiler supply water temperature is more than sufficient, the

control decreases the boiler target temperature. If the control does not ha e a requirement for heat from the boiler, it does not

show a boiler target temperature. Instead, “– – –” is displayed in the LCD.

BOILER DIFFERENTIAL (Boil DIFF)

An on / off heat source such as a boiler must be operated with a differential to pre ent short cycling. This differential is centered

around the Boil TRG temperature. If the boiler supply temperature drops ½ of the differential below the Boil TRG temperature,

the control closes the boiler contact to fire the boiler. If the boiler supply temperature rises ½ of the differential abo e the

Boil TRG temperature, the control opens the boiler contact to turn off the boiler. With the control, either a fixed or automatic

differential setting is selected. If the AUTO differential is selected, the control automatically adjusts the boiler differential setting

under the current load conditions to a oid short cycling.

BOILER MINIMUM (Boil MIN)

The Boil MIN is the lowest water temperature that the control is

allowed to use as a Boil TRG temperature. During mild conditions, if

the control calculates a Boil TRG temperature that is below the Boil

MIN setting, the Boil TRG temperature is adjusted to at least the

Boil MIN setting. During this condition, if the boiler is operating, the

Minimum pointer turns on in the LCD while the Boil TRG or the Boil

SUP temperature is iewed. If the installed boiler is designed for

condensing operation, set the Boil MIN adjustment to OFF.

BOILER MAXIMUM (Boil MAX)

The Boil MAX is the highest water temperature that the control

is allowed to use as a Boil TRG temperature. If the control does

target Boil MAX, and the Boil SUP temperature is near the Boil MAX

temperature, the Maximum pointer turns on in the LCD while the

Boil TRG or the Boil SUP temperature is iewed. At no time does the

control operate the boiler abo e 248°F (120°C).

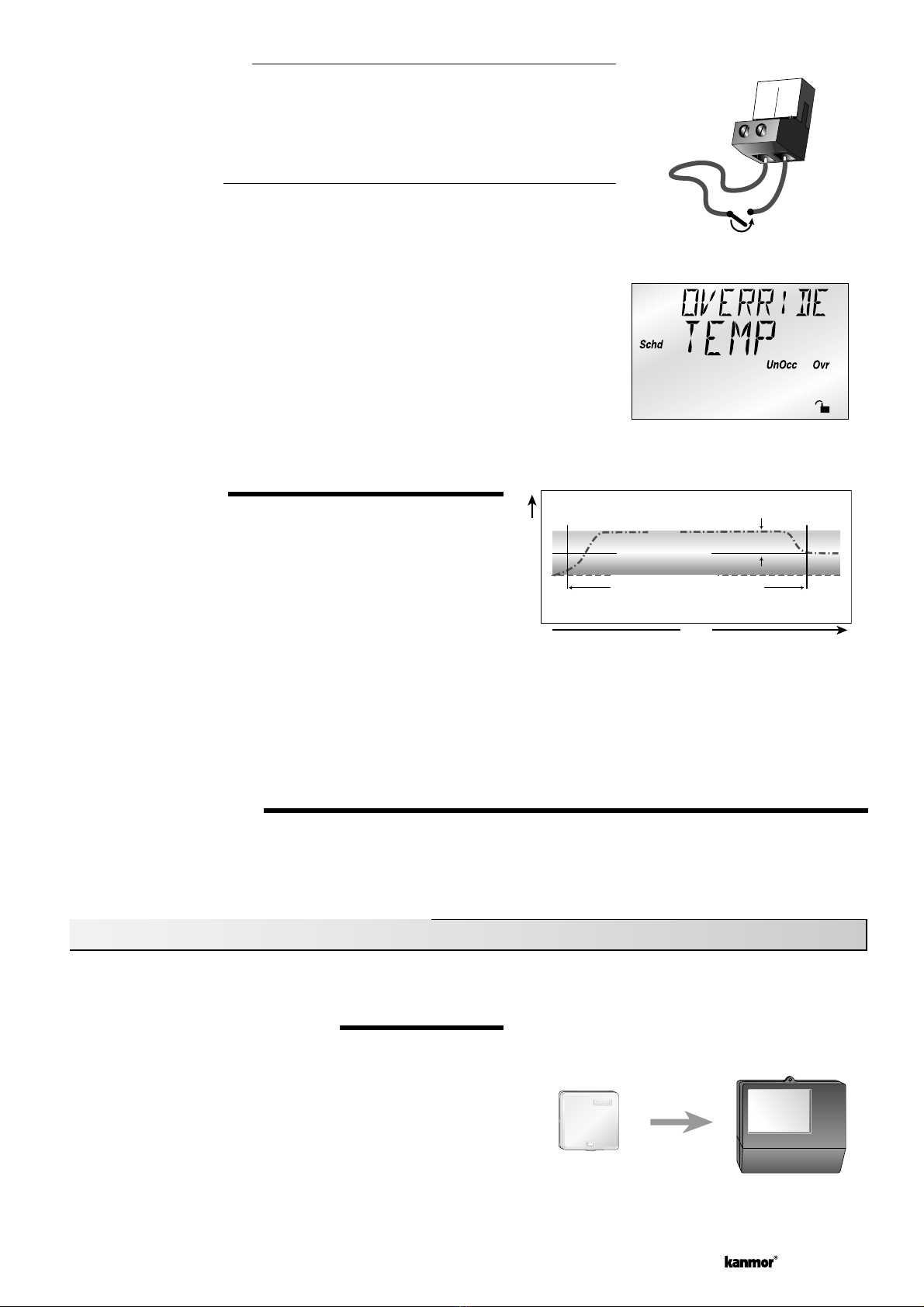

BOILER PROTECTION (Boil MIN)

The control is capable of pro iding boiler protection from cold mixing system return water temperatures. If the boiler sensor

temperature is cooler than the Boil MIN setting while the boiler is firing, the control reduces the output from the mixing de ice.

This limits the amount of cool return water to the boiler and allows the boiler temperature to reco er. This feature can only be

used if the Boil SENS item is not set to NONE.

BOILER OPERATION

When the control determines that boiler operation is required, the Boiler contact terminals (6 and 7) close. While the boiler

contact is closed, the burner segment in the LCD is displayed.