7

Table of Contents

Geng Started .................................................................................................................... 9

Installaon Basics.............................................................................................................. 10

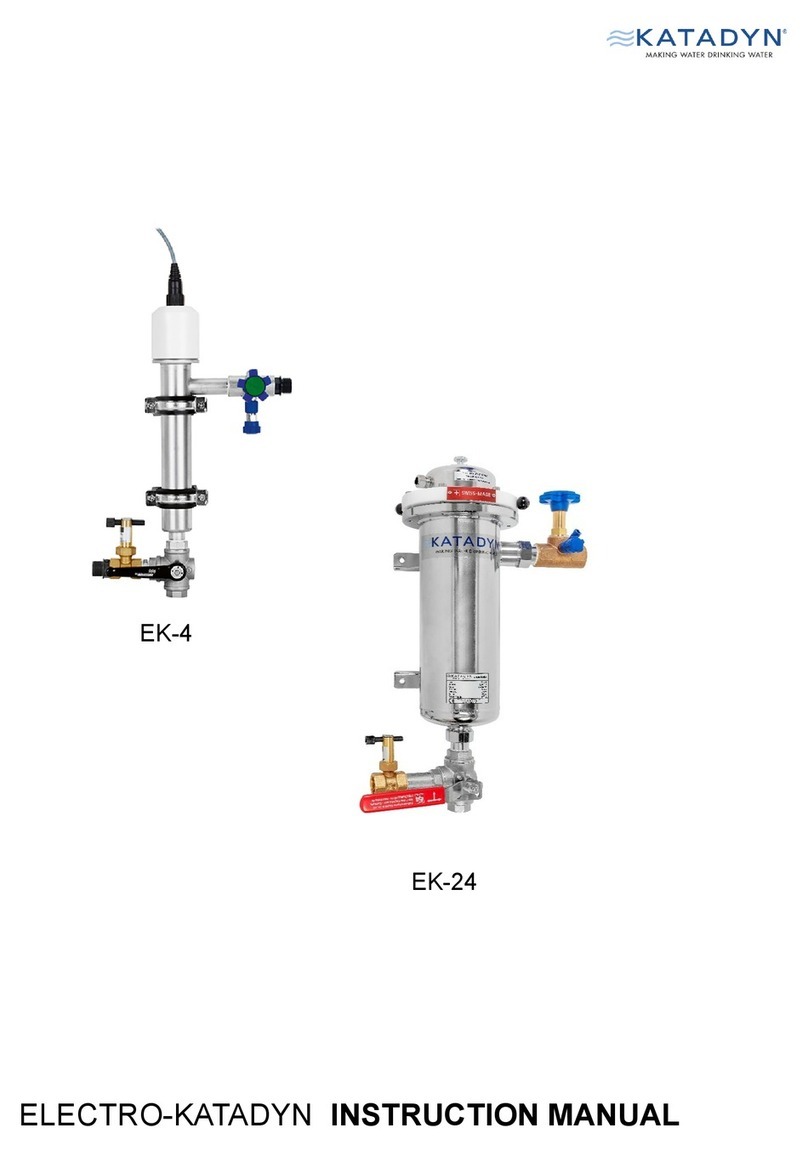

Components ...................................................................................................................... 11

Catalina Plumbing Schemac & Plumbing Detail..............................................................13

Product Water Plumbing and Pressure Gauge Tube Installaon ..................................... 15

Plumbing Detail ................................................................................................................. 18

Tube Fing Assembly Procedures....................................................................................20

Electrical ............................................................................................................................ 22

Installing A Remote Controller..........................................................................................25

Oponal Tank Switch Installaon ..................................................................................... 26

Operaon ...........................................................................................................................

New Systems Start Up and Tesng ...................................................................................28

Dry Tesng with an Arcial Ocean..................................................................................29

Spectra Remote Manual Controller Guide........................................................................30

Freshwater Flush Calibraon ............................................................................................ 31

Adjusng Fresh Water Flush Duraon ..............................................................................32

Normal Operaon and Fresh Water Flush........................................................................ 33

Nominal Operang Parameters ........................................................................................33

Maintenance, Storage, and Troubleshoong ..........................................................

Maintenance .....................................................................................................................34

Introducon to Spectra Chemicals....................................................................................38

Storage Procedures ...........................................................................................................39

Winterizing with Propylene Glycol....................................................................................40

Membrane Cleaning Procedure ........................................................................................ 41

Suggested Spares...............................................................................................................42

Troubleshoong ................................................................................................................ 43

Catalina Flow Test .............................................................................................................46

Poor Water Quality............................................................................................................ 48

Technical Bullens............................................................................................................. 49

Spectra Remote Manual Controls...............................................................................

Wiring Schemac...............................................................................................................53

Control Box Wiring ............................................................................................................ 54

Exploded Views and Part Numbers........................................................................ 56

Owner Resources.............................................................................................................

Warranty, Product Registraon, Installaon & Commissioning Reports.........................65