EN

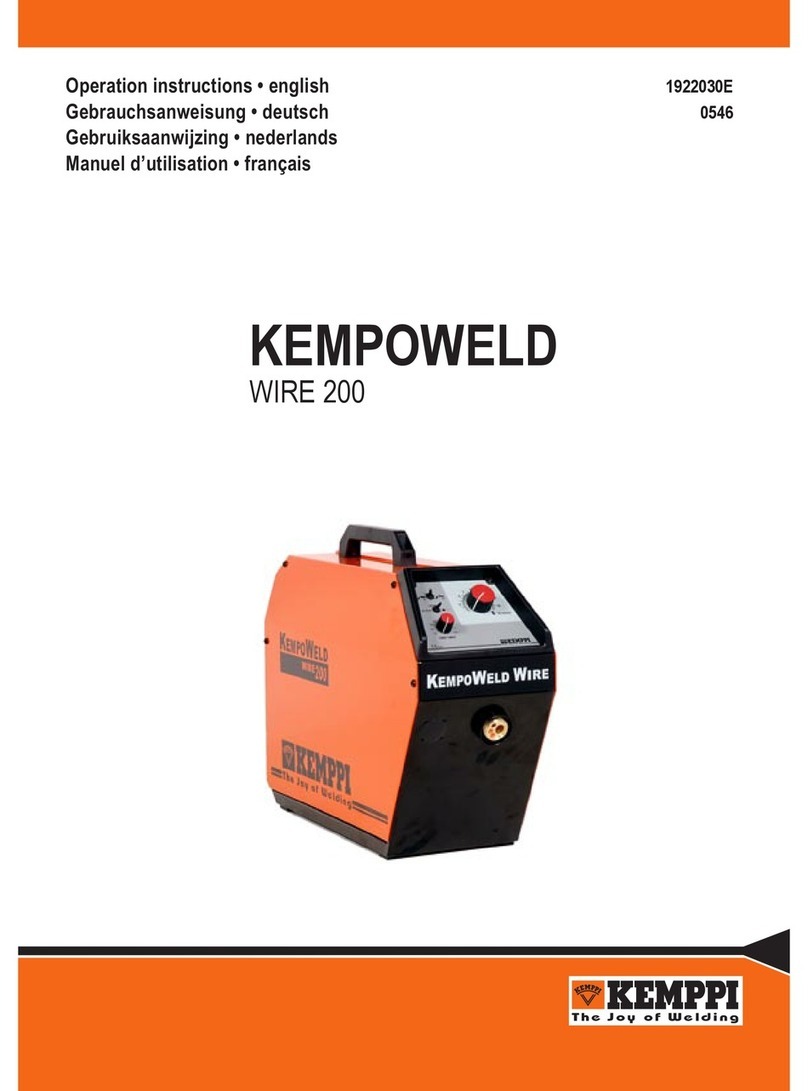

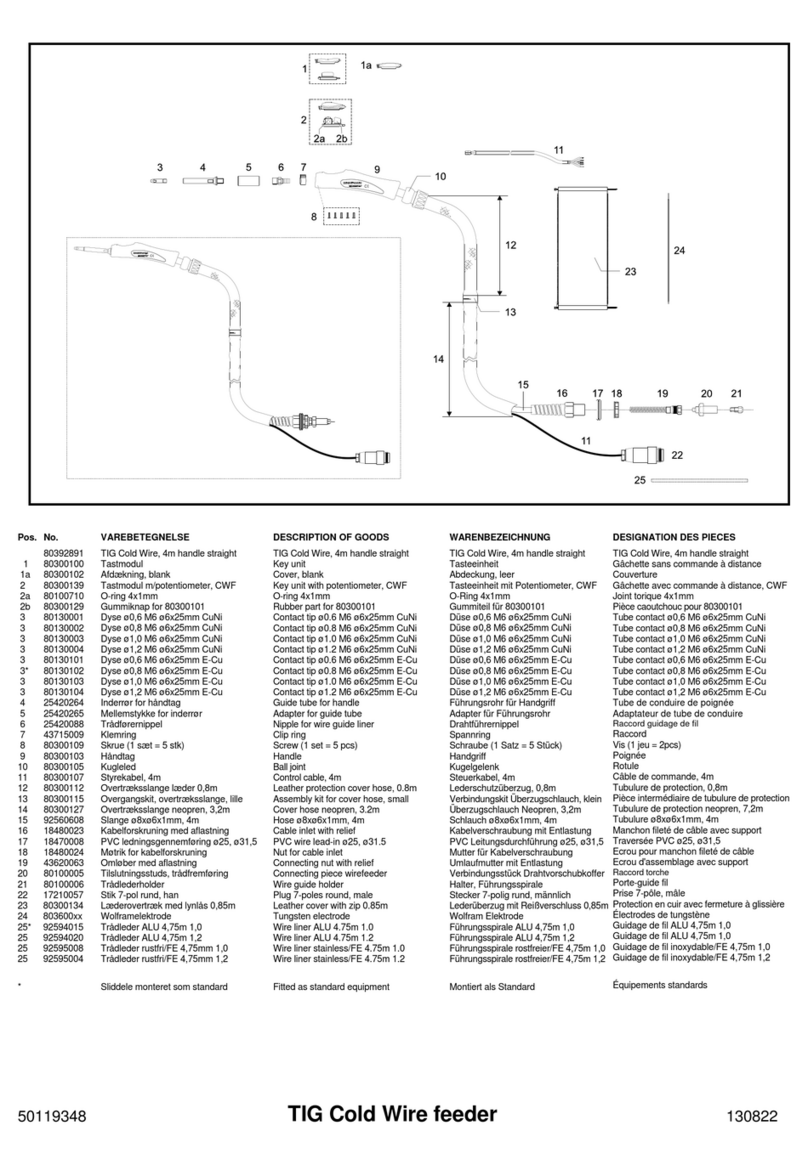

To feed the wire from the spool to the welding gun:

1. Open the pressure arm of the wire feed mechanism and lift the top roll holder to its up

position.

2. Draw some loose wire from the spool and push it through the straightening rolls at

the back of the mechanism. You can loosen the bottom straightening roll with the

adjustment screw located below it.

3. Adjust the straightening rolls so that the wire is rmly fed into the drive roll.

4. Push the wire over the feed roll groove and through the front wire guide until it comes

out from the Euro connector by about 150mm.

5. Replace the top feed roll holder over the wire and close the pressure arm.

6. Cut away any deformed wire section and dress the sharp wire tip as described above.

7. Connect the welding gun and tighten the collar.

8. Press the Wire inch button and allow the ller wire to feed through the gun cable to the

contact tip.

3.3 Setting the pressure of the feed rolls

To make ller wire run smoothly into the wire liner and to the welding gun you can adjust the

pressure of the feed rolls of the wire feed mechanism.

To increase the pressure applied to the welding ller wire, turn the black pressure

adjustment knob in a clockwise direction.

To decrease the pressure applied to the welding ller wire, turn the black pressure

adjustment knob in an anti-clockwise direction.

There is a graduation scale marked on the arm of the adjustment knob. The more pressure

applied, the greater the number of graduation marks visible.

For hard steel and stainless steel ller wires, make sure there is sucient pressure applied, so

avoiding ller wire slippage in the feed rolls.

NOTE! Too much pressure may atten the ller wire, damage its coating, cause friction and

excessive wear to drive roll bearings and therefore reduced life.

3.4 Setting the spool brake force

To prevent the ller wire from uncoiling on overrun following use at high feed speeds, you can

change the brake force of the welding spool.

The spool brake adjustment screw is located inside the spool hub. To adjust the brake force,

unscrew the spool locking mechanism on the tip of the wire spool hub.

To increase the force turn the screw clockwise, and to decrease it, by turn the screw

anticlockwise.

NOTE! Do not over tighten, and reduce the pressure for light ller wire types.

3.5 Changing the feed rolls

The drive roll has two dierent sized grooves in it. You can choose which groove to use by

opening the drive roll securing screw and turning the drive roll other way round. The size of

the groove currently in use is facing outward.

HF 10E, 10P

8