R01.0 16/05/2019 Page 3

Table of contents:

1Safety instructions ................................................................................................. 4

1.1 Notes on symbols and instructions ........................................................................................................... 4

1.2 Basic safety information ........................................................................................................................... 5

1.3 Appropriate use ........................................................................................................................................ 5

1.4 Notes for Pacemakers and Defibrillators .................................................................................................. 6

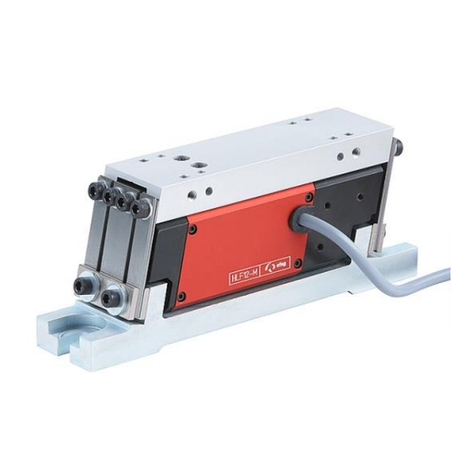

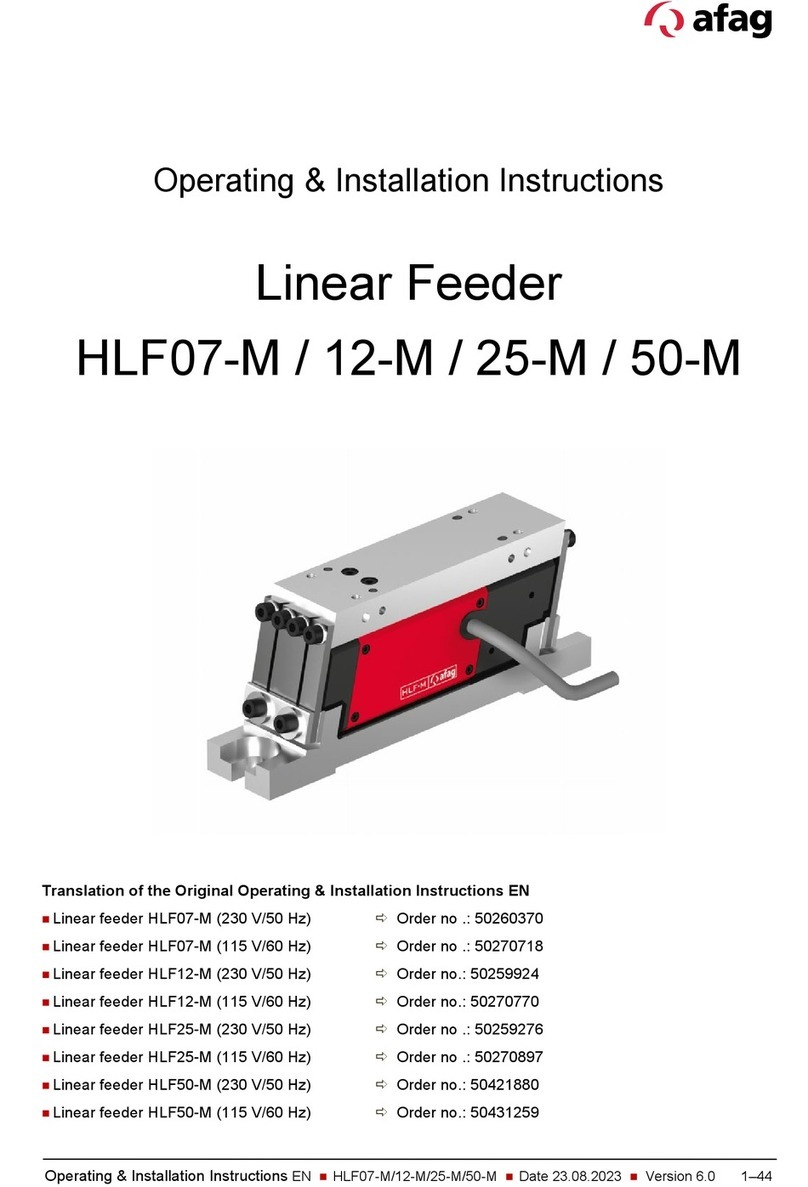

2Description of the device....................................................................................... 7

2.1 General ..................................................................................................................................................... 7

2.2 Functional description............................................................................................................................... 7

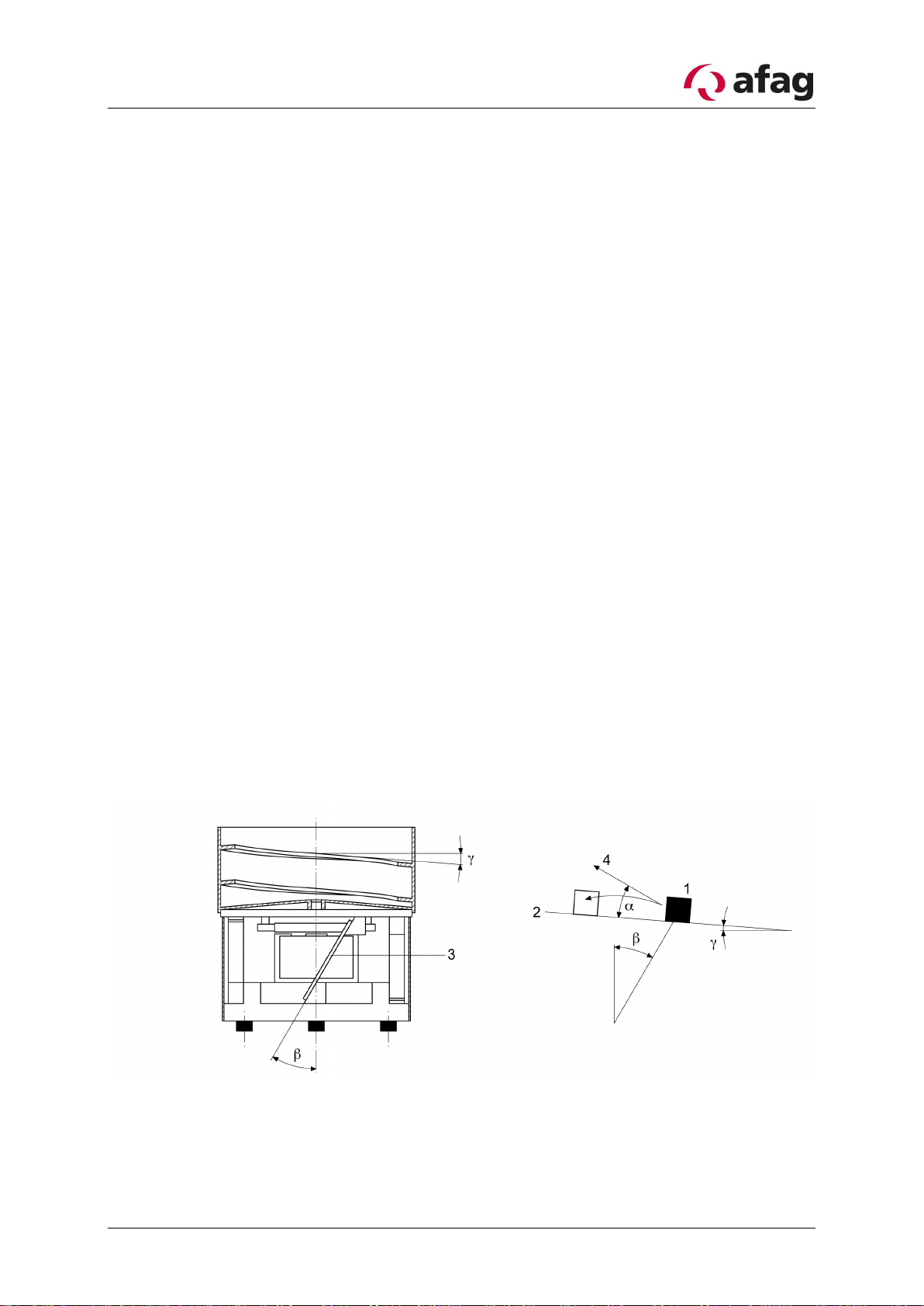

2.3 Definition of the feed direction ................................................................................................................. 8

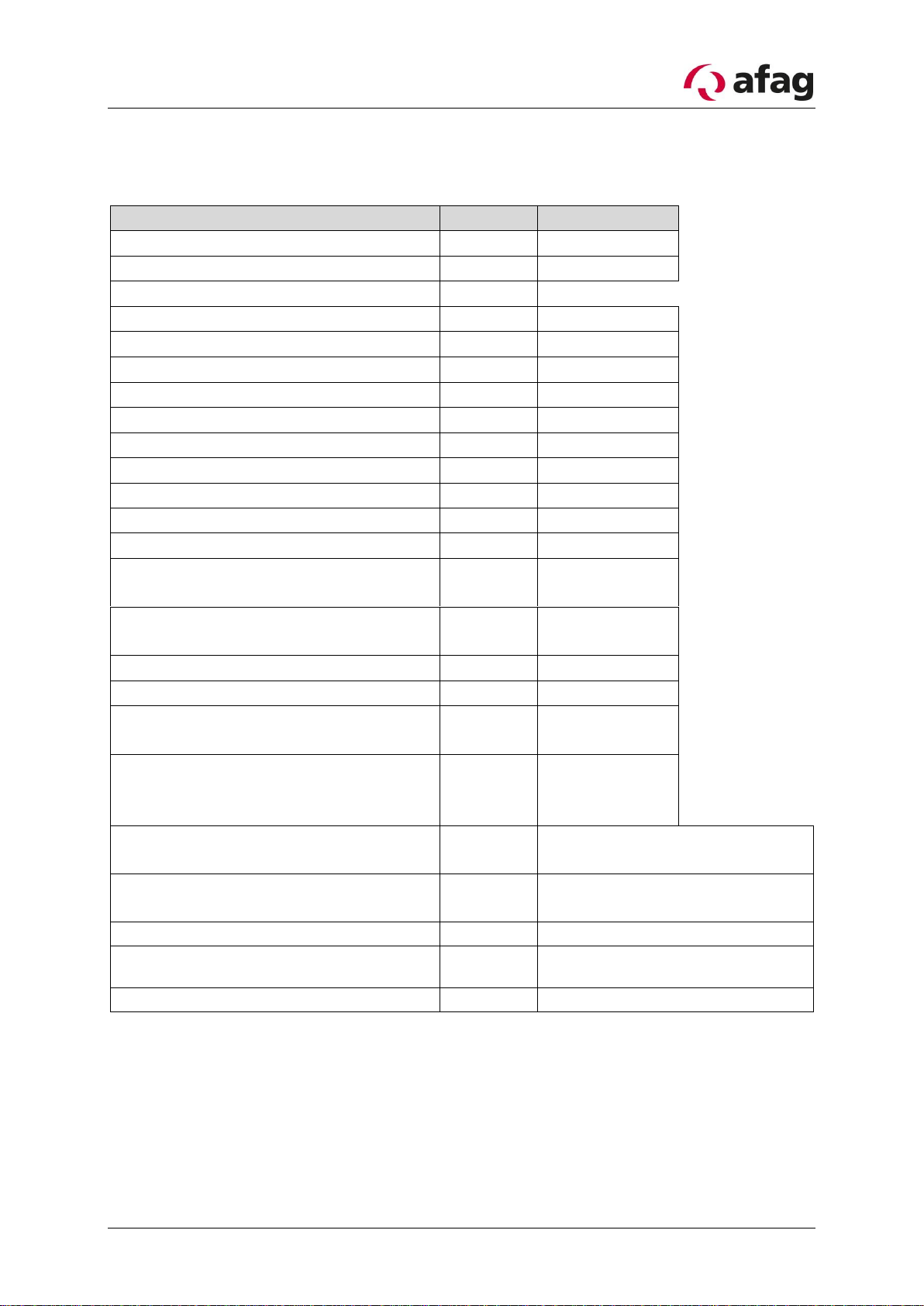

2.4 Technical data........................................................................................................................................... 9

3Assembly instructions......................................................................................... 10

3.1 Transport ................................................................................................................................................ 10

3.2 Installing the unit .................................................................................................................................... 10

3.3 Requirements for the bowl ..................................................................................................................... 11

3.4 Information for the construction of selection elements.......................................................................... 11

3.5 Power supply........................................................................................................................................... 11

4Operating instructions......................................................................................... 12

4.1 Correlations between the transport speed and the WV spring packages............................................... 12

4.2 Torques ................................................................................................................................................... 14

5Maintenance guidelines ....................................................................................... 15

5.1 Troubleshooting and fault repair ............................................................................................................ 15

5.2Cleaning .................................................................................................................................................. 17

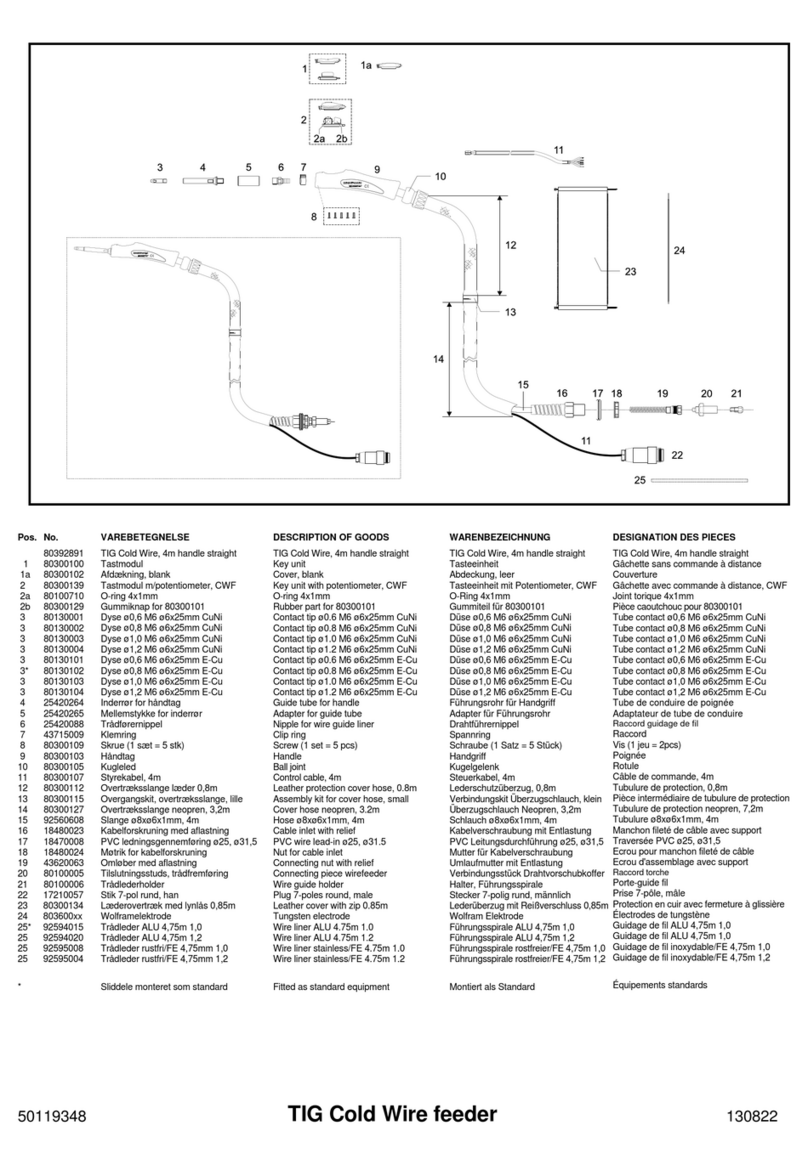

5.3 Wear and Spare parts ............................................................................................................................. 17

6Accessories .......................................................................................................... 19

6.1 Mounting parts ....................................................................................................................................... 19

6.2 Control device ......................................................................................................................................... 19

6.3 Address for orders................................................................................................................................... 20

7Disposal ................................................................................................................ 21