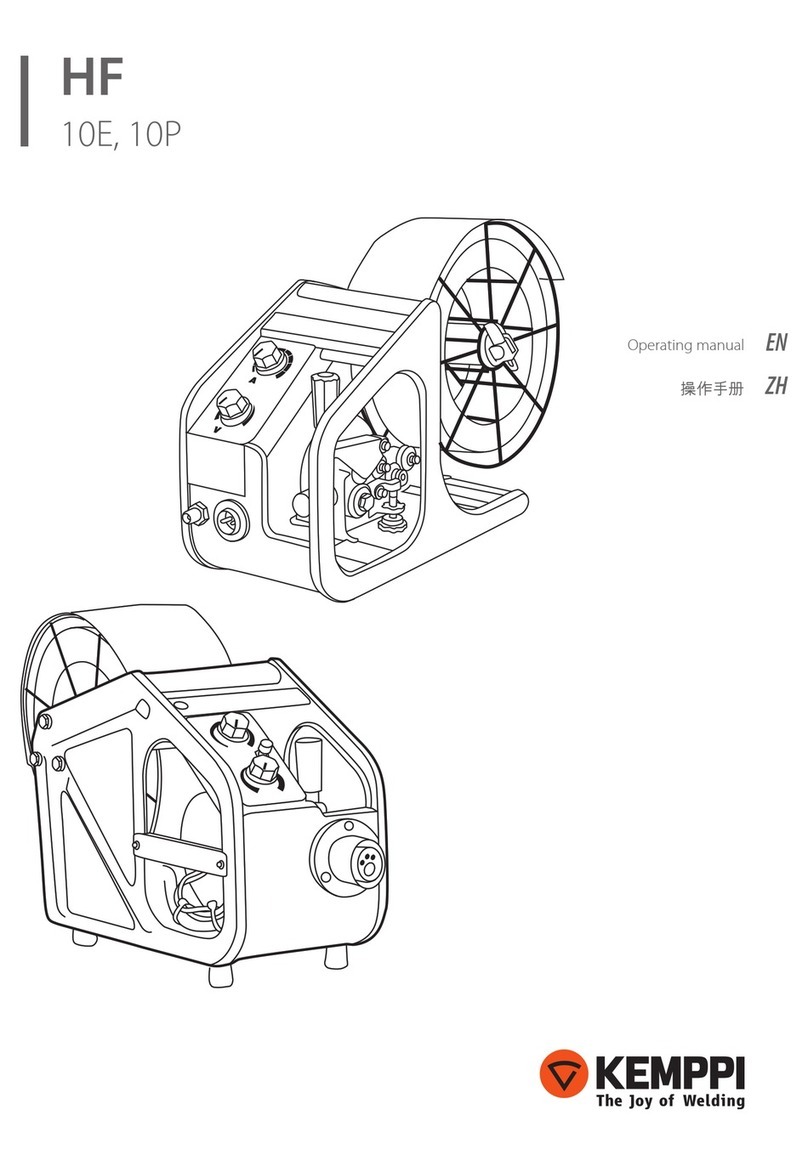

KEMPOWELD WIRE 200 / 0546 – 7© KEMPPI OY

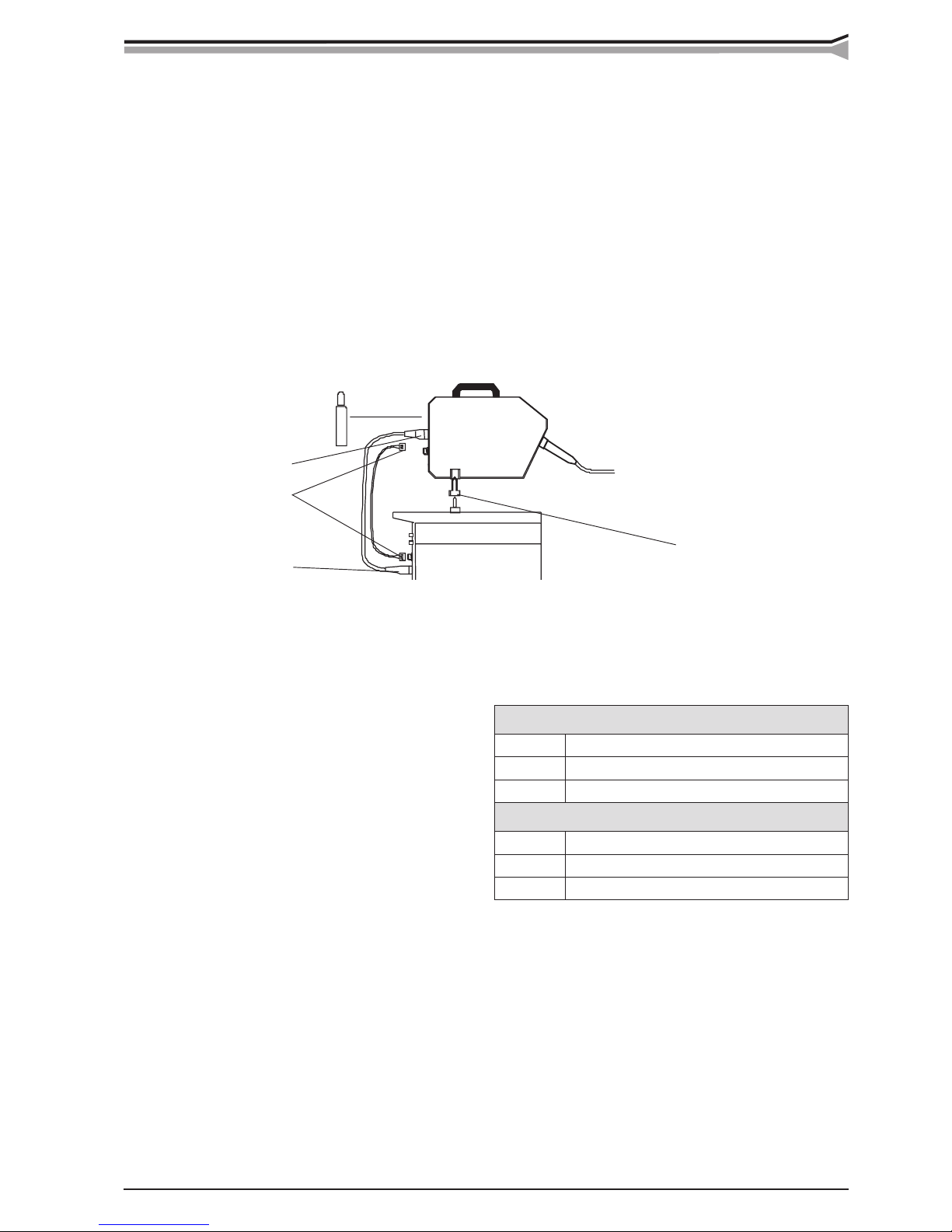

4. ASSEMBLY OF KEMPOWELD EQUIPMENT

Kempoweld power source: Read chapter “Installation” in the Operation Instructions of the power source.

Wire feed unit:

1. Mount wire feed unit on the pin on the power source cover.

2. Mount control cable and welding current cable to the connectors to the rear walls and return current cable

to the connector on Kempoweld front panel.

3. Welding current polarity: When the connection has been done according to the markings, the gun has positive

voltage. In order to change polarity, interchange the welding and return current cable ends connection to the

power source.

4. Connect the interconnection cable plugs with the corresponding sockets in units.

5. If the wire feed unit is mounted to boom, it may not have galvanic contact with lift hook and boom.

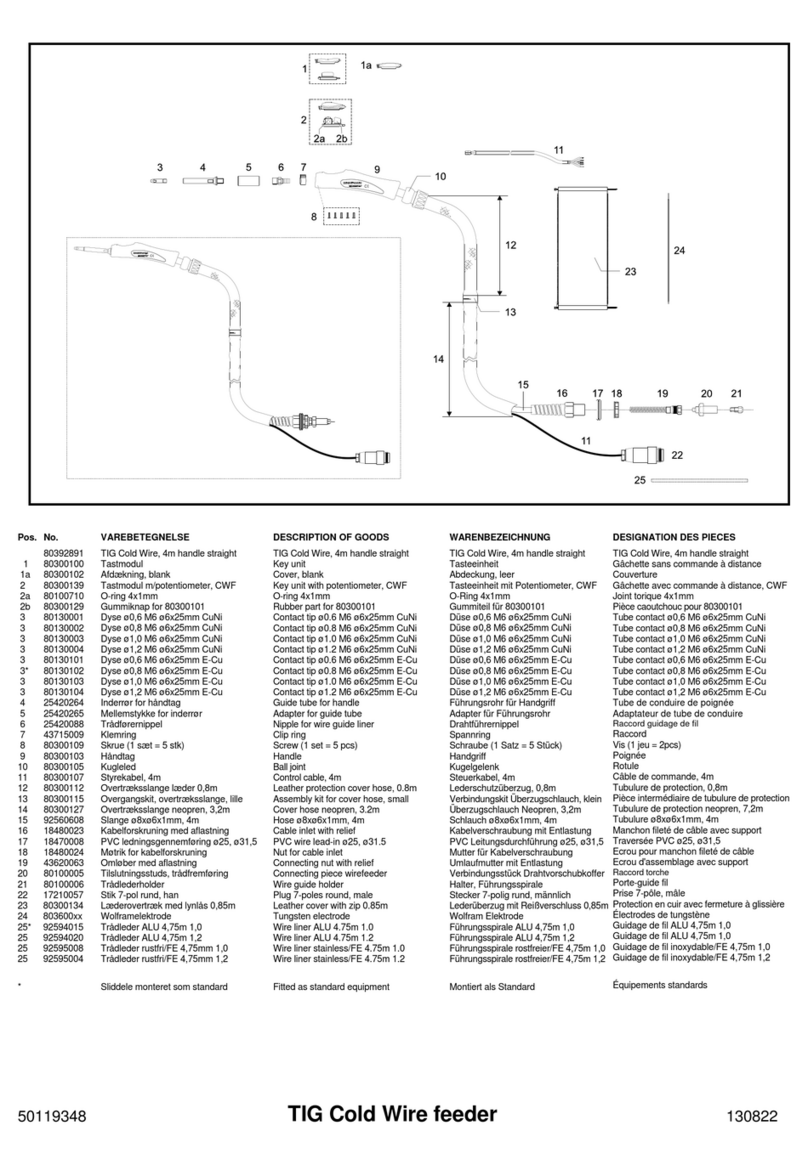

6. MIG-gun is connected with EURO connector. Use guide tubes and contact tips according to manufacturer´s

operation instructions. Accessories which are too tight or otherwise unsuitable for the wire type used, will

cause disturbances and excessive stress on accessories.

Bearing bushing

DIX connector

Amphenol connectors

DIX connector

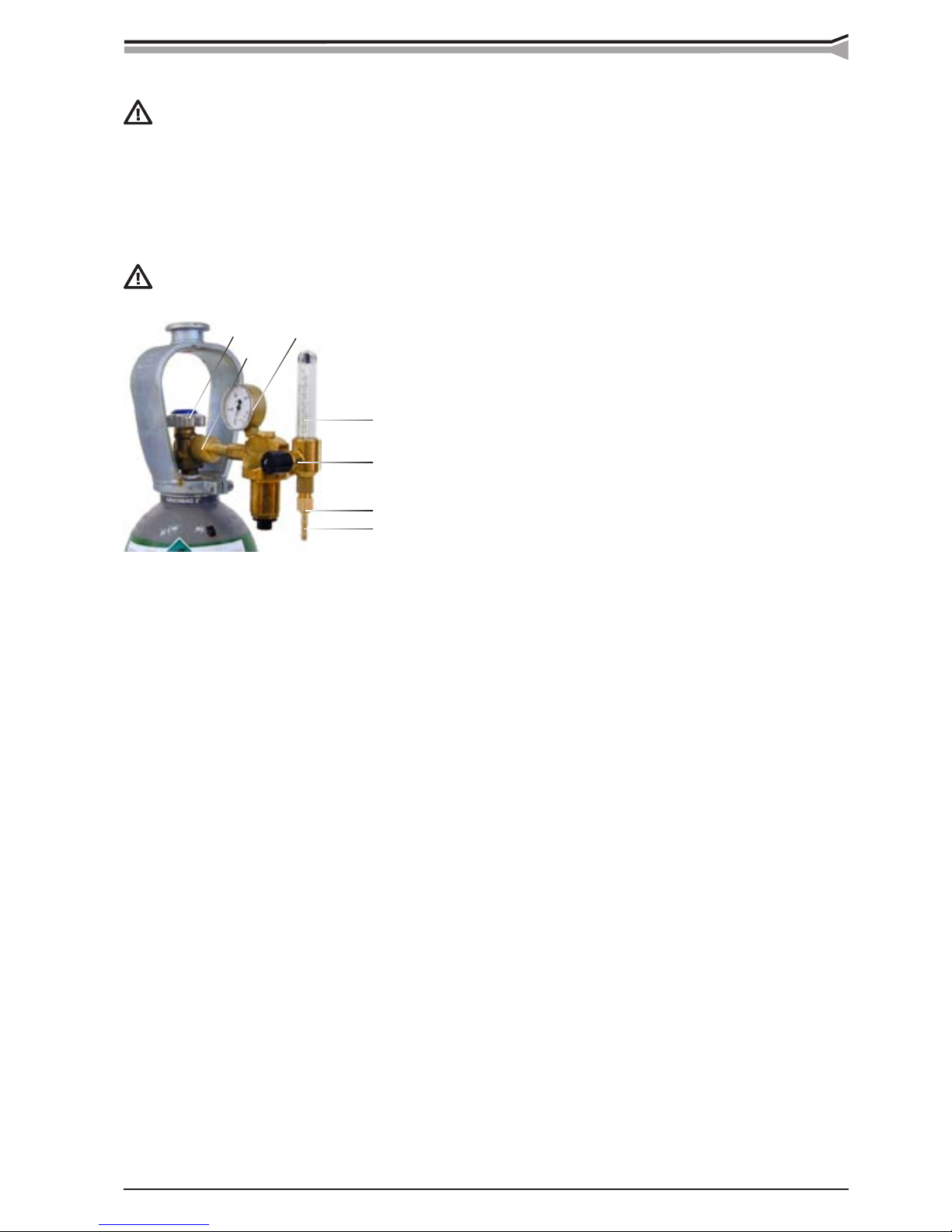

7. Shielding gas hose is mounted to the rear wall of wire feed unit. For installing gas bottle and shielding gas

flow adjustment, see the paragraph Shielding gas.

5. INSTALLATION

5.1. ACCESSORIES CORRESPONDING TO WIRE DIAMETER

Feed rolls

colour filler wire ø mm (inch)

white 0.6 and 0.8 (0.030)

red 0.9/1.0 and 1.2 (0.035, 0.045 and 0.052)

Guide tubes

colour filler wire ø mm (inch)

white 0.6 and 0.8 (0.030)

orange 0.9-1.6 (0.035, 00.45 and 0.052)

The wire feed rolls have two grooves for different filler wire diameters. Correct wire groove is chosen by moving

selecting washer from one side of feed roll to another. The feed rolls and wire guide tubes of wire feed unit have

colour codes in order to make identification easier (see table on page 4). On delivery the Kempoweld WIRE 200 is

equipped with red feed rolls with plain groove and with orange wire guide tubes for welding filler wires of 0.9-1.2

mm (0.035", 0.045" and 0.052").

5.2. INSTALLING MIG WELDING GUN

To ensure problem-free welding, check in the Operation Instructions of the gun that the wire guide tube and contact

tip are in accordance with the manufacturer´s recommendation, and suitable to be used for wire feed diameter

and type in question. An overly tight wire guide tube may cause excessive stress on wire feed unit, resulting in

disturbances in wire feed.

Screw the snap connector of gun tightly, to avoid voltage losses on connecting surface. A loose connection will heat

gun and wire feed unit. After tightening, check that guide tube inside connector is not in contact with feed rolls.

The wire feed rolls are available with plain groove,

knurled groove and with trapezoidal groove for different

purposes.

Feed rolls with plain groove:

1. Universal feed roll for welding of all kind of wires.

2. Special feed rolls for heavy duty use.

Feed rolls with knurled groove:

Special feed roll for cored wires and steel wires.

Feed rolls with trapezoidal groove:

Special feed roll for aluminium wires.