Contents

1 General information................................................................................................................................................... 7

1.1 Using these Operating Instructions...................................................................................................................... 7

1.2 Conventions in use............................................................................................................................................... 7

1.3 Safety instructions and notices ............................................................................................................................ 7

1.4 Terminology used................................................................................................................................................. 8

1.5 Abbreviations used............................................................................................................................................... 9

2 Safety instructions................................................................................................................................................... 11

2.1 General safety instructions................................................................................................................................. 11

2.2 Disposal ............................................................................................................................................................. 11

3 Product description ................................................................................................................................................. 12

3.1 Proper and intended usage................................................................................................................................ 12

3.1.1 Standard applications............................................................................................................................ 12

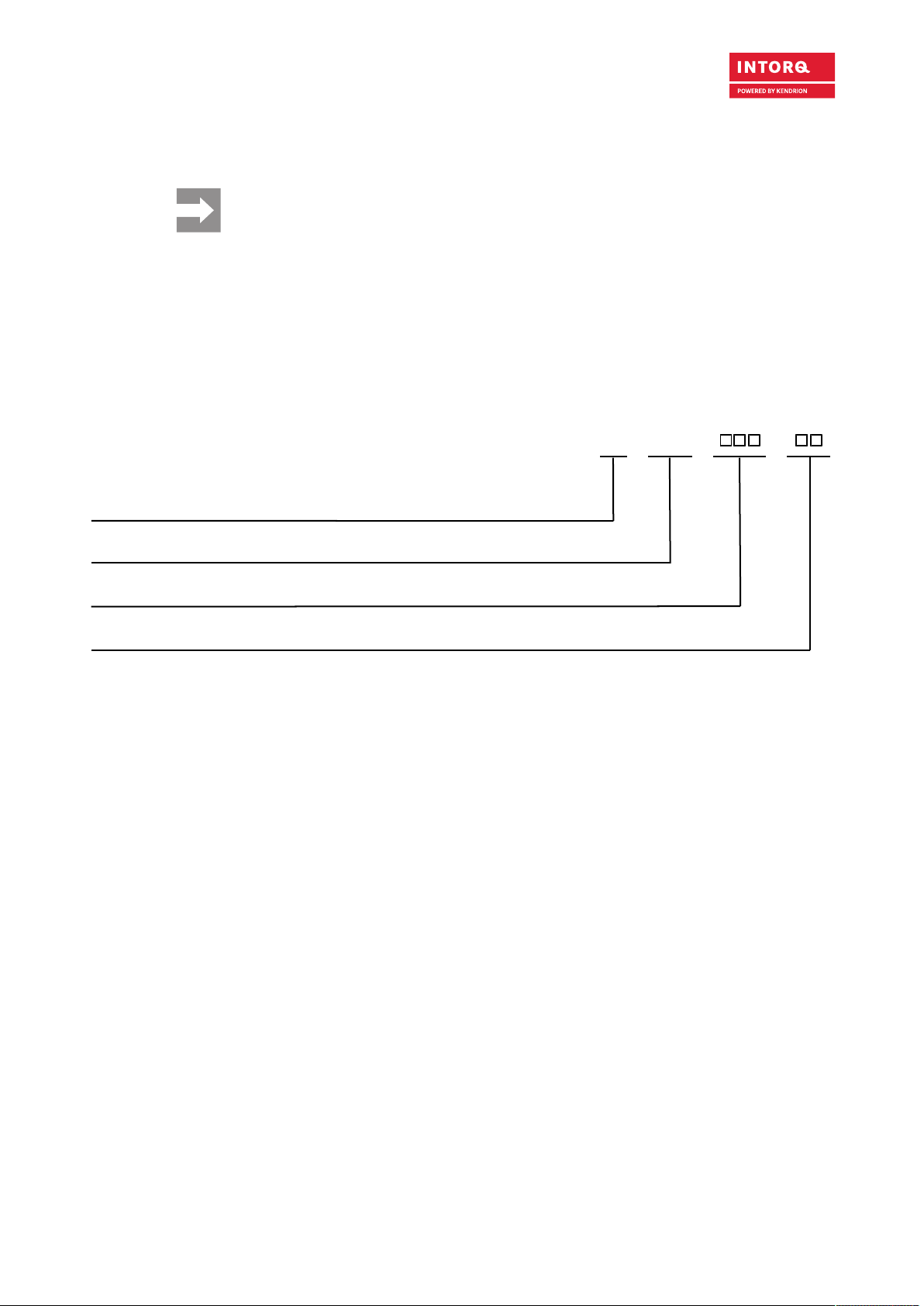

3.2 Layout ................................................................................................................................................................ 12

3.2.1 Basic module......................................................................................................................................... 12

3.2.2 Compact module ................................................................................................................................... 13

3.3 Function ............................................................................................................................................................. 13

3.4 Braking and release ........................................................................................................................................... 14

3.5 Project planning notes........................................................................................................................................ 14

3.6 Optional configuration ........................................................................................................................................ 14

3.6.1 Hand-release (optional)......................................................................................................................... 14

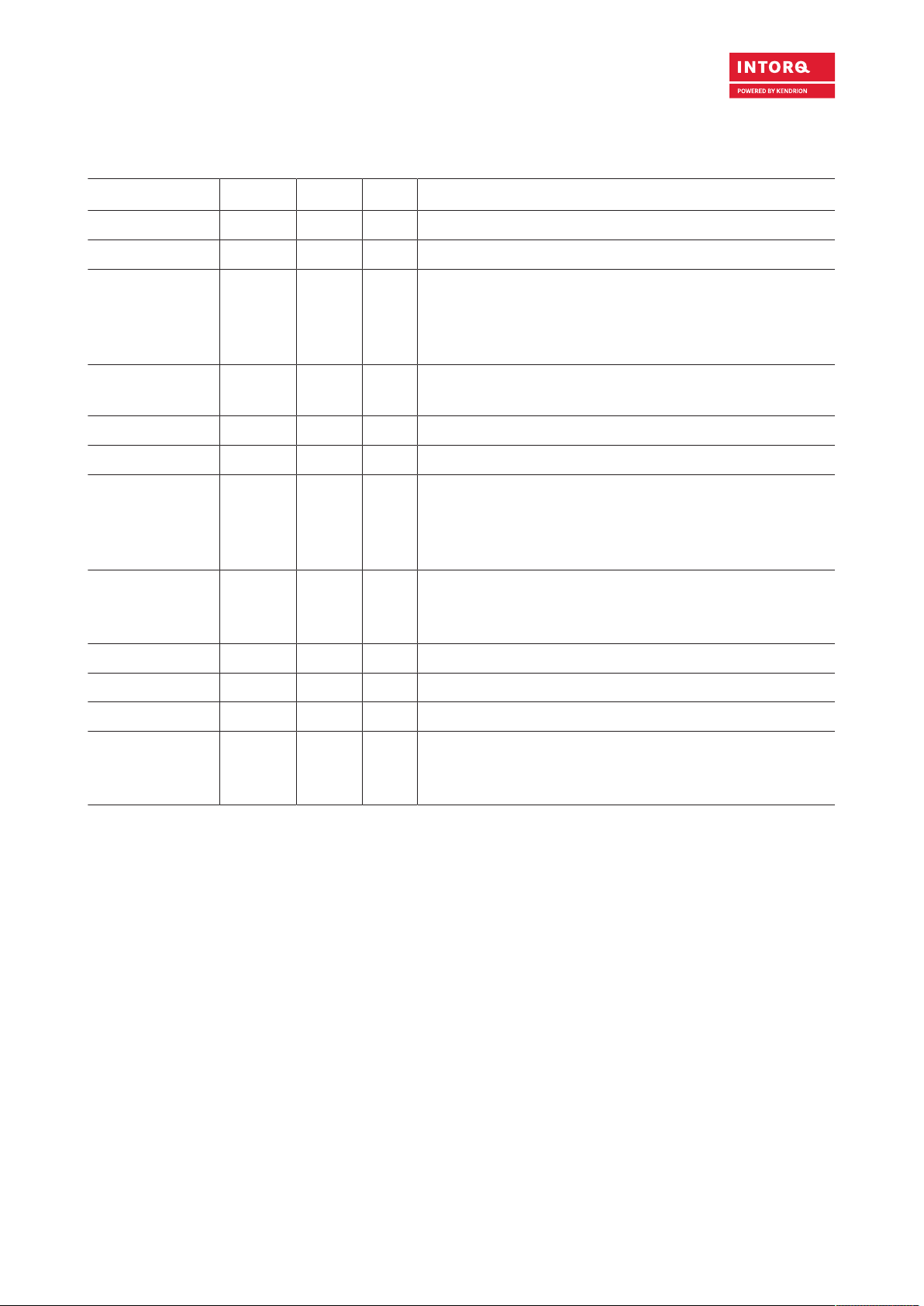

4 Technical specifications.......................................................................................................................................... 15

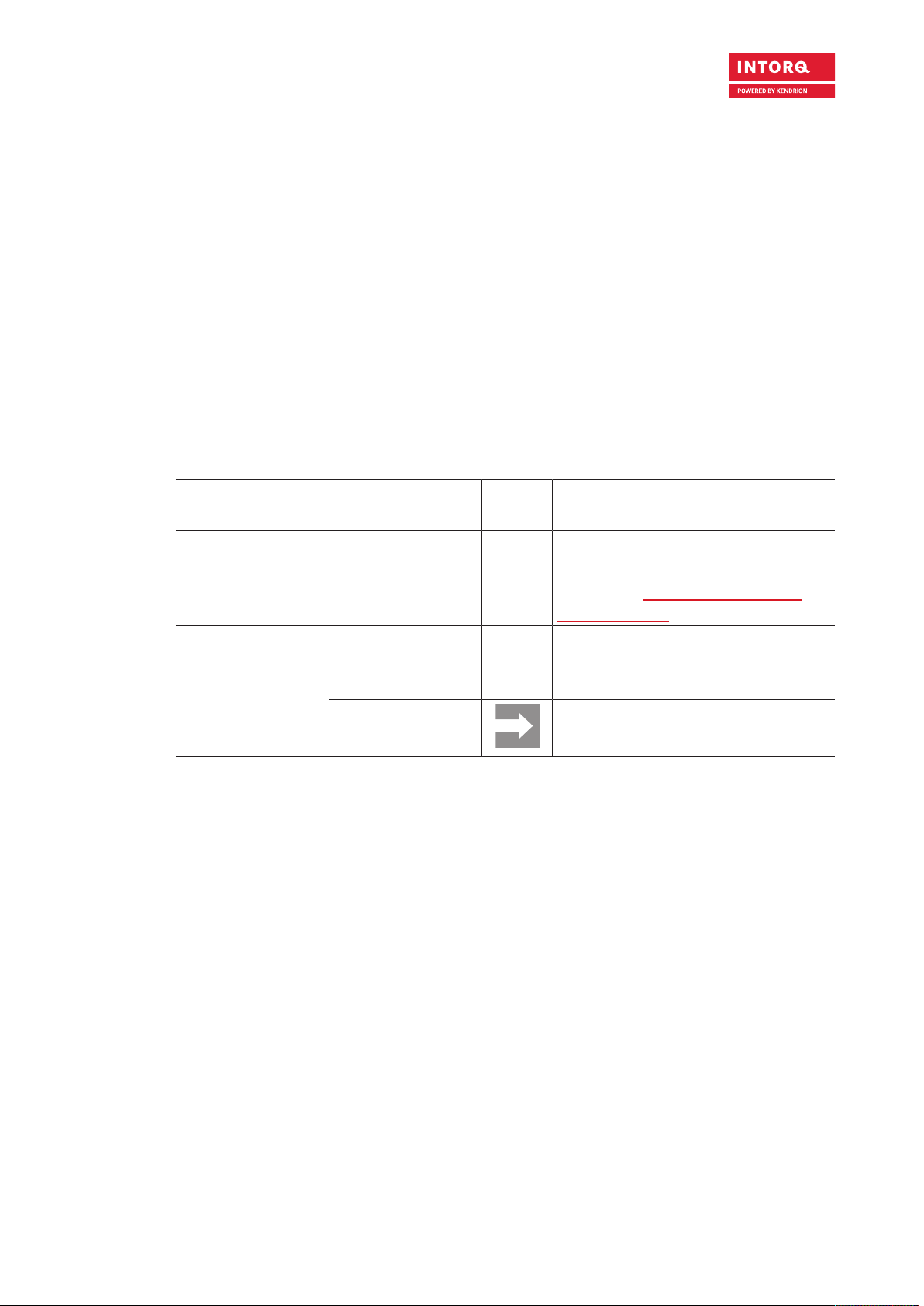

4.1 Possible applications of the Kendrion INTORQ spring-applied brake................................................................ 15

4.2 Characteristics ................................................................................................................................................... 15

4.3 Switching times .................................................................................................................................................. 19

4.4 Friction work / operating frequency.................................................................................................................... 21

4.5 Electromagnetic compatibility............................................................................................................................. 22

4.6 Emissions........................................................................................................................................................... 22

4.7 Labels on product............................................................................................................................................... 23

Kendrion INTORQ | BA 14.0164 | 02/2022 4