Operating Instructions BA 77 600..A00 // Last updated: 13/03/2020 // Page 2 of 33

Contents

1. General information .............................................................................................................................. 3

1.1 Introduction ............................................................................................................................................ 3

1.2 Standards and directives ....................................................................................................................... 3

1.3 Declaration of Incorporation (in accordance with Annex II, part 1, Section B of Machinery Directive

2006/42/EC)........................................................................................................................................... 3

1.4 Declaration of Conformity ...................................................................................................................... 4

1.5 Manufacturer's liability ........................................................................................................................... 4

1.6 Brake versions ....................................................................................................................................... 4

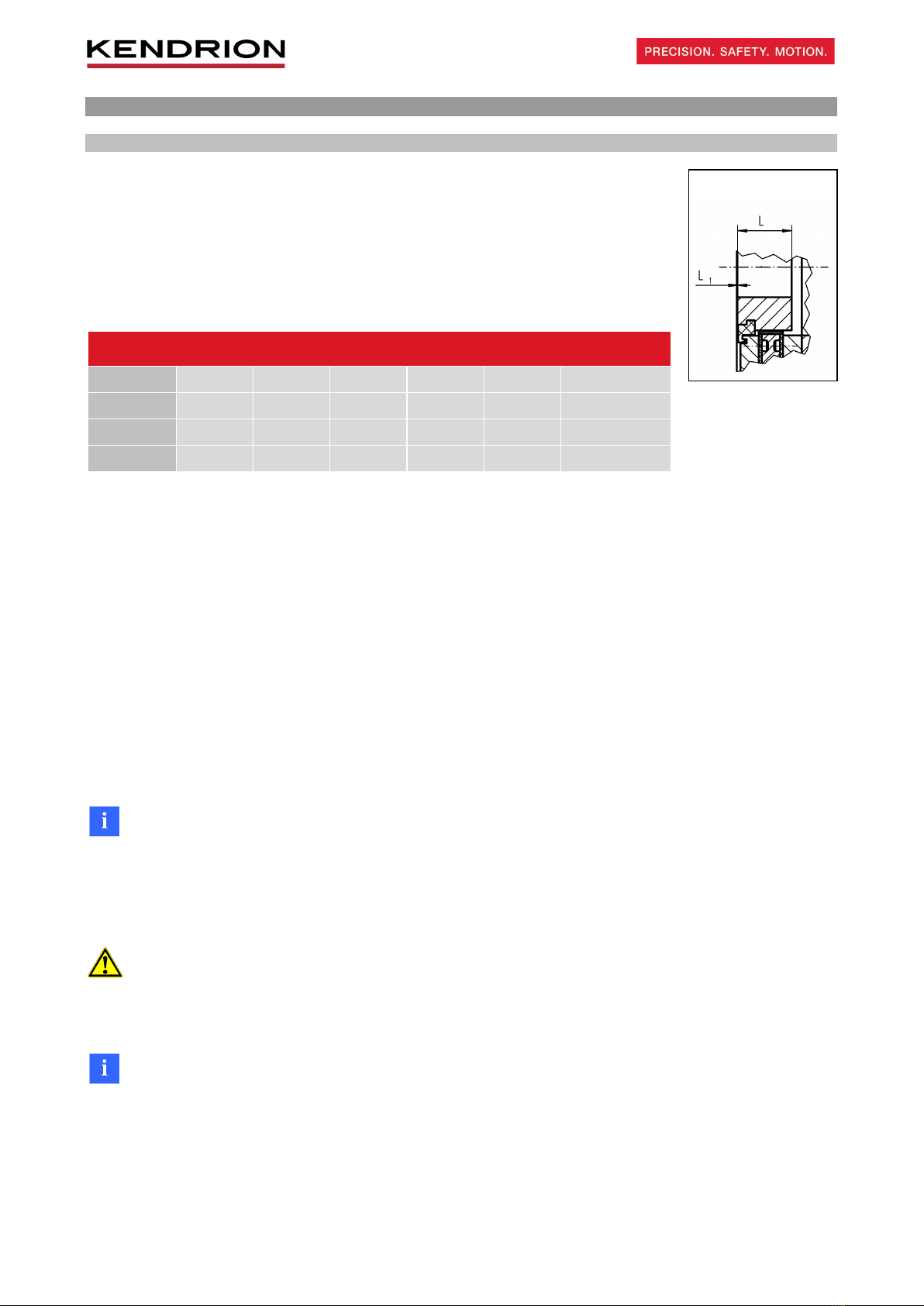

2. Product description............................................................................................................................... 5

2.1 Operating principle................................................................................................................................. 5

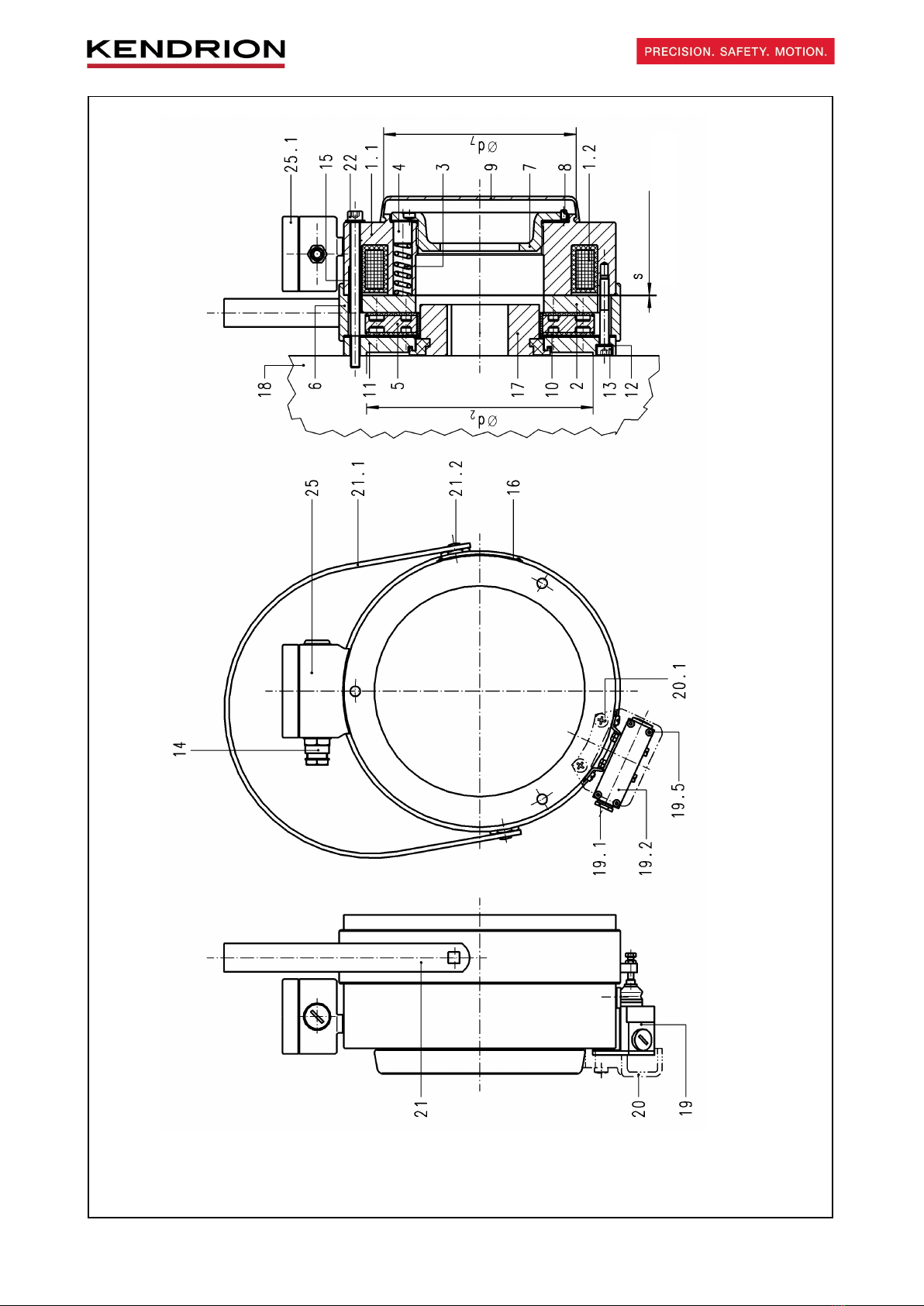

2.2 Design.................................................................................................................................................... 5

3. Installation.............................................................................................................................................. 8

3.1 Mechanical installation........................................................................................................................... 8

3.2 Installation of accessories...................................................................................................................... 9

3.3 Electrical connection and operation..................................................................................................... 10

3.3.1 DC power supply ............................................................................................................................. 11

3.3.2 AC power supply.............................................................................................................................. 11

3.3.3 Microswitch (19) connection ............................................................................................................ 13

3.4 Electromagnetic compatibility .............................................................................................................. 15

3.5 Set-up and start-up .............................................................................................................................. 18

3.5.1 Functional checks ............................................................................................................................ 18

3.5.2 Manual brake release ...................................................................................................................... 19

3.6 M2rated torque adjustments................................................................................................................ 19

4. Maintenance......................................................................................................................................... 20

4.1 Checks and service ............................................................................................................................. 20

4.2 Microswitch (19) adjustment (only applicable to brakes with microswitch (19)).................................. 21

4.3 Spare parts and accessories ............................................................................................................... 22

5. Condition at delivery........................................................................................................................... 22

6. Emissions............................................................................................................................................. 22

6.1 Noise.................................................................................................................................................... 22

6.2 Heat ..................................................................................................................................................... 23

7. Troubleshooting .................................................................................................................................. 23

8. Safety.................................................................................................................................................... 24

8.1 Intended use ........................................................................................................................................ 24

8.2 General safety information................................................................................................................... 24

8.2.1 Set-up .............................................................................................................................................. 25

8.2.2 Set-up and start-up .......................................................................................................................... 25

8.2.3 Installation........................................................................................................................................ 25

8.2.4 Operation ......................................................................................................................................... 25

8.2.5 Maintenance, repair and replacement ............................................................................................. 26

8.3 Warning symbols ................................................................................................................................. 26

9. Definitions ............................................................................................................................................ 27

10. Technical specifications..................................................................................................................... 29

11. Product number / type number / version number............................................................................ 32

12. Specialist repair shops ....................................................................................................................... 32

13. Revision history................................................................................................................................... 32

Document information:

Issued by: Kendrion (Villingen) GmbH Last updated: 13/03/2020

Replaces document: - Replaces the issue dated: 30/12/2009

Document type:translation of original German operating Document status: released

instructions BA 77 600..A00

Document title: BA 77 600..A00 Englisch