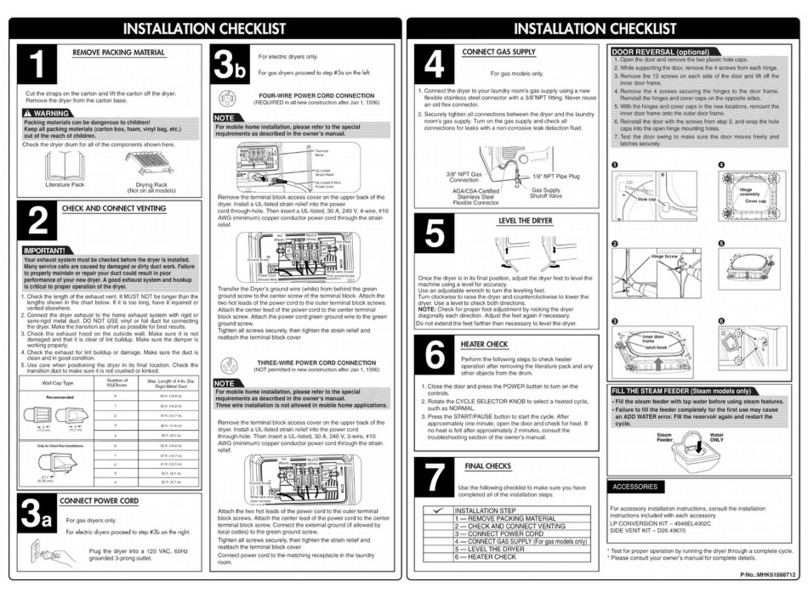

2

POWER SUPPLY CORD - The dryer is equipped with a 120

volt3-wirepowercord.

NOTE: Do not under

any circumstances

remove grounding

prong from plug.

GASDryer

CIRCUIT - Individual 15 amp. branch circuit fused with a 15

amp. maximum time delay fuse or circuit breaker.

POWER SUPPLY - 3 wire, 120 volt single phase, 60 Hz,

AlternatingCurrent.

OUTLET

RECEPTACLE

(COPPER)

3 WIRE GROUNDED NEUTRAL

120-240 VOLT 60 CYCLE

MAIN FUSE BOX

30 AMP DELAYED ACTION

FUSES

OR CIRCUIT BREAKER

NEUTRAL WIRE

NEMA 10-30R (COPPER)

SUBJECT TO LOCAL

REGULATIONS

POWER SUPPLY

GROUNDING PRONG

EXHAUST SYSTEM REQUIREMENTS

Useonly4inch(10.2cm) diameter (minimum) rigid or flexible

metal duct and approved vent hood which has a swing-out

damper(s)thatopenwhenthedryeris in operation. When the

dryerstops,thedampersautomaticallyclosetopreventdrafts

and the entrance of insects and rodents.To avoid restricting

theoutlet,maintainaminimumof12inches(30.5cm)clearance

betweentheventhoodandthegroundoranyotherobstruction.

The following are specific requirements

for proper and safe operation of your dryer. Failure to

follow these instructions can create excessive drying

times and fire hazards.

Do not use plastic flexible duct to exhaust the dryer.

Excessivelint can build upinside exhaust system andcreate

afirehazardandrestrictairflow.Restrictedairflowwillincrease

dryertimes. If yourpresent system is madeup of plasticduct

or metal foil duct, replace it with a rigid or flexible metal duct.

Ensurethe present ductisfree ofanylint priortoinstalling

dryer duct.

If the dryer is not exhausted outdoors, some fine lint will

be expelled into the laundry area. An accumulation of lint in

any area of the building can create a health and fire hazard.

The dryer exhaust system MUST be exhausted to the

outside of the building!

Donotallowcombustiblematerials(forexample:clothing,

draperies/curtains, paper) to come in contact with exhaust

system. The dryer MUST NOT beexhausted into a chimney,

a wall, a ceiling, or any concealed space of a building which

can accumulate lint, resulting in a fire hazard.

Exceeding the length of duct pipe or number of elbows

allowed in the "MAXIMUM LENGTH" charts can cause an

accumulation of lint in the exhaust system. Plugging the

system could create a fire hazard, as well as increase drying

times.

Do not screen the exhaust ends of the vent system, nor

use any screws or rivets to assemble the exhaust system.

Lintcanbecomecaughtinthescreen,onthescrewsorrivets,

clogging the duct work and creating a fire hazard as well as

increasingdryingtimes.Useanapprovedventhoodtoterminate

the duct outdoors, and seal all joints with duct tape.All male

ductpipefittingsMUST beinstalled downstream with the flow

ofair.

PRE-INSTALLATION REQUIREMENTS

Tools and Materials Required for Installation:

1. Phillipshead screwdriver.

2. Channel-lockadjustablepliers.

3. Carpenter'slevel.

4. Flatorstraightbladescrewdriver.

5. Duct tape.

6. Rigid or flexible metal 4 inch (10.2 cm) duct.

7. Vent hood.

8. Pipethread sealer(Gas).

9. Plastic knife.

ELECTRICAL REQUIREMENTS

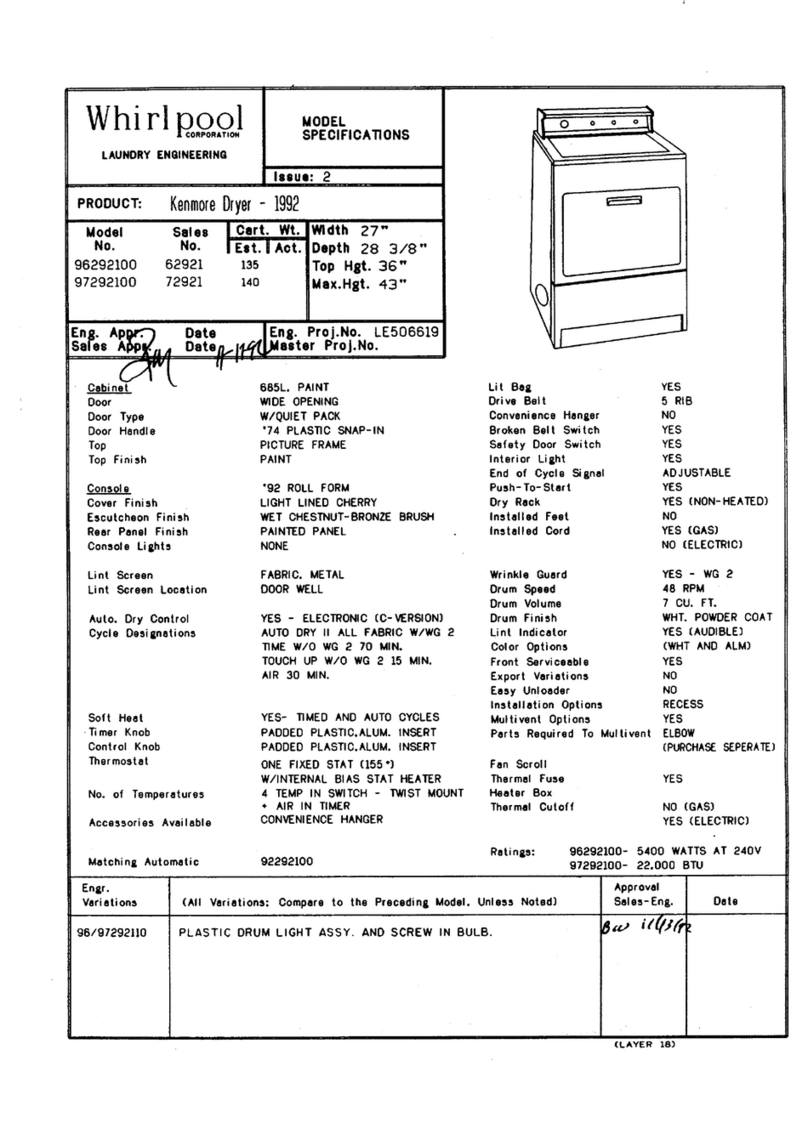

ELECTRICDryer

CIRCUIT-Individual 30amp.branchcircuitfusedwith30amp.

minimum time delay fuses or circuit breakers.

POWER SUPPLY - 3 wire, 240 volt, single phase, 60 Hz,

AlternatingCurrent.

POWER SUPPLY CORD KIT -The dryerMUST employ a 3-

conductor power supply cord NEMA 10-30 type SRDT rated

at240 voltAC minimum, 30 amp., with 3open end spadelug

connectorswithupturnedendsorclosedloopconnectorsand

marked for use with clothes dryers, OR a4-conductor power

supplycordNEMA14-30type SRDT or ST(asrequired)rated

at240 voltAC minimum, 30 amp., with 4open end spadelug

connectorswithupturnedendsorclosedloopconnectorsand

marked for use with clothes dryers. See ELECTRICAL

CONNECTIONSFORA4-WIRE SYSTEM.

OUTLETRECEPTACLE-NEMA10-30R or14-30Rreceptacle

to be located so the power supply cord is accessible when

the dryer is in the installed position.

Typical 3-wire installation

Explosion hazard. Do not install the dryer

wheregasoline or other flammablesare kept or stored.Ifthe

dryer is installed in a garage, it must be a minimum of 18

inches