Air Shutter _

adjustment

Fig. 5

5. Air Shutters - Surface Burners

The air shutter (adjustment)for each of the (4) top burners is

located at the open end of the venturi tube and sets on the

orifice of the valve. Should the air shutter need adjusting,

rotate the air shutters to allow more or less air into the venturi

burner tubes as needed (See Fig. 5).

Ifthe air isproperly adjusted, the flame will be steady, relatively

quiet, and have approximately 1/2" sharp blue cone (Usually

adjusted to FULL OPEN).

If the flame is yellow in color, increase air shutter opening size.

If the flame is a distinct blue, but lifting away from the burner,

reduce the air shutter opening size.

6. Air Shutter - Oven Burner

The air shutterwill need to be adjusted to FULL OPEN position

when appliance isconverted for use with LP/Propane gas. The

approximate flame length of the oven burner is 1 inch (with a

distinct inner blue flame - See Fig. 6).

1" Flame Burner

_ Baffle

Fig. 6

To determine if the oven burner flame is proper:

a. To access the air shutter you must remove the broiler

drawerorloweroven panel.

b. Remove the oven bottom by removing the screws at rear

of oven bottom. Lift up the rear of oven bottom and slide

toward back of appliance to disengage from front of oven

front frame.

c. Remove burner baffle by removing nut located on top of

baffle and two screws from front edge of oven front frame.

Lift baffle straight up and out of the oven.

d. Settheoventobakeat350°Fandobservetheflame. Ifthe

flame isyellow in color, increase air shutter opening size.

Ifthe flame is a distinct blue color, but lifting away from the

burner; reduce the air shutter opening size.

e. Turn offoven and allow to cool before adjusting air shutter.

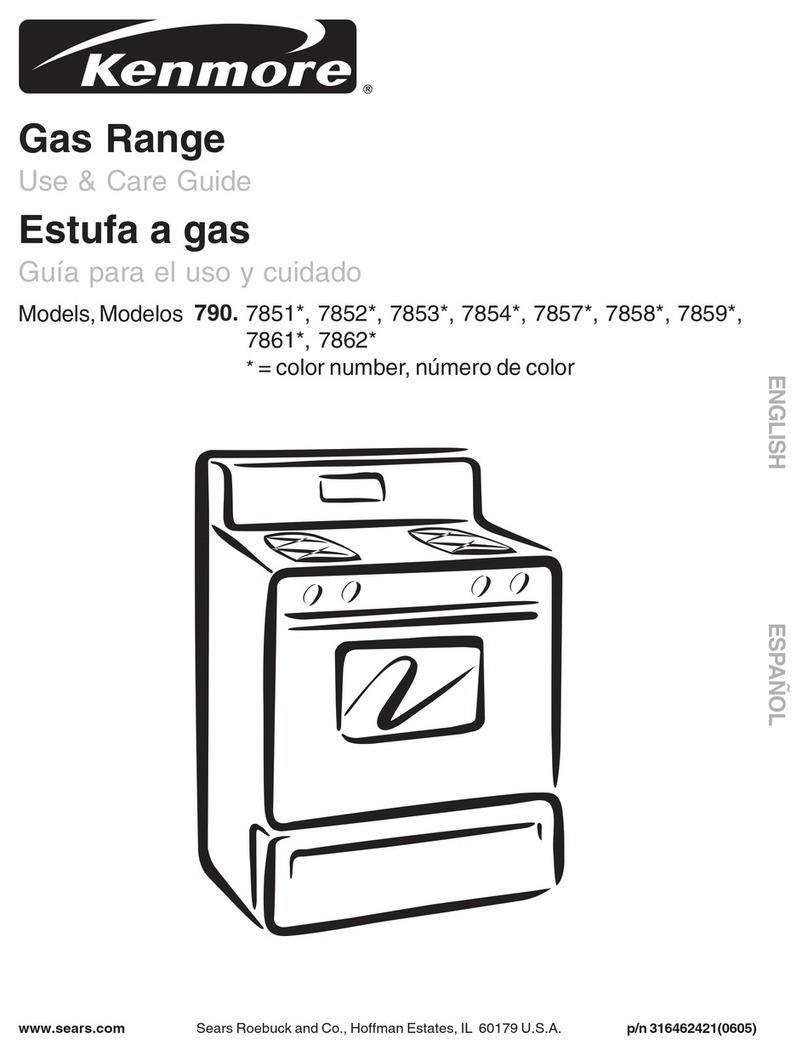

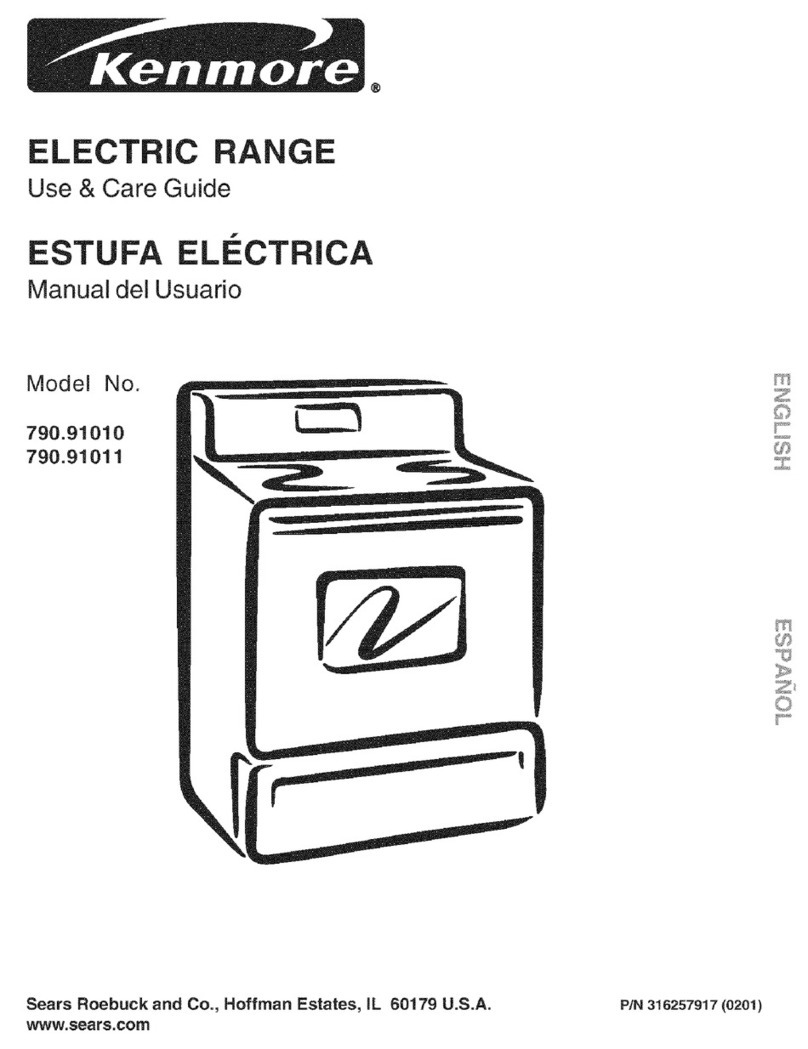

To adjust loosen Air Shutter Lock Screw (See Fig. 7),

reposition air shutter to FULL OPEN and tighten Air

Shutter Lock Screw. Retest the burner by repeating step

"d" above. When the burner flame is a distinct blue color

burning steady, the air shutter is adjusted correctly.

f. Replaceburnerbaffleandoven bottom.

g. Lower the cooktop and replace oven broiler drawer or

lower oven front panel.

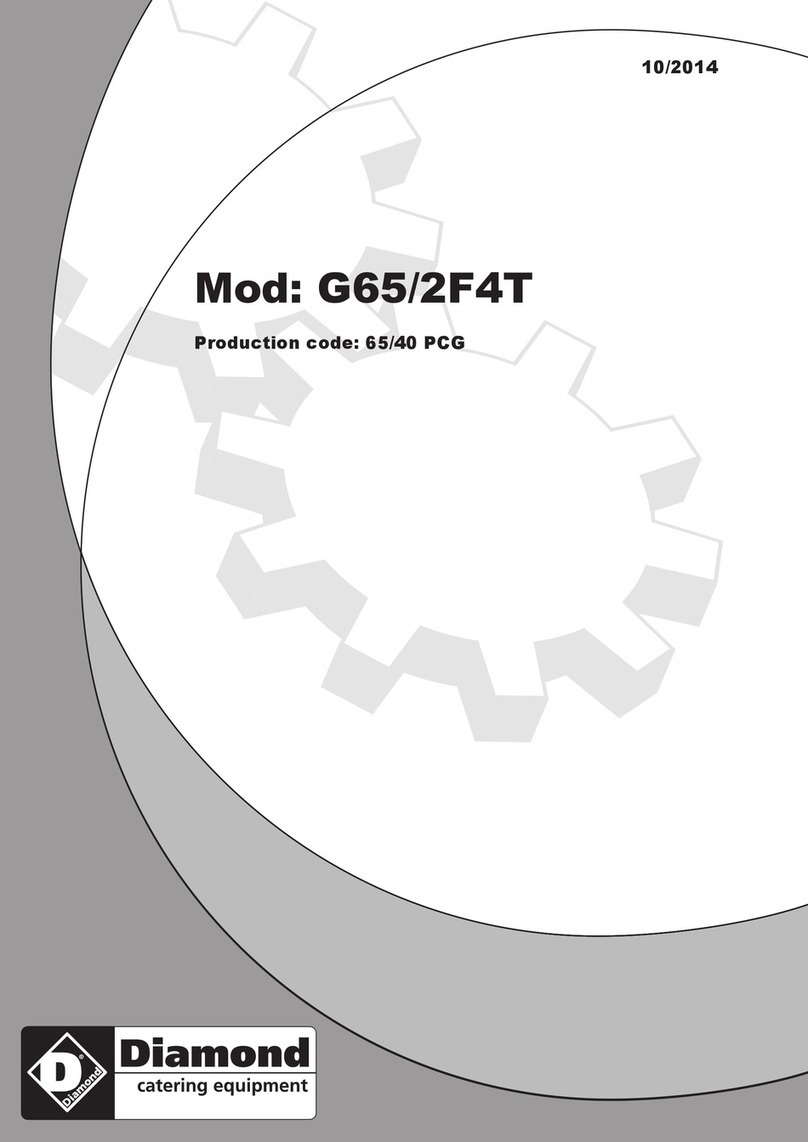

i/ Oven

il /4,,,, Burner

I I

Shutter __ _

Lock _! i_] I I

Scre

Air

Shutter ............._- _ Orifice

I _ Hood

I I

__1

Fig. 7

Conversion to Natural Gas

If it becomes necessary to convert the appliance back to

natural gas:

a. Disconnect gas and electrical supply from appliance.

b. Convert pressure regulator (See step 1), turn pressure

regulator cap over so the solid end of cap faces away from

pressure regulator. Place the hollow end of the pressure

regulator cap into the loop end of the plastic dust protector.

Tighten the pressure regulator cap using a 5/8" open-end

wrench tothe pressure regulator. DO NOT OVERTIGHTEN.

c. Remove thefour LP surface burner orifices using 10mm

nutdriver (or 10mm open-end wrench) and replace with the

4 original factory installed natural gas orifices.

d. Convert Oven Burner Orifice for Natural Gas by loosening

spud counter-clockwise (approximately 2-1/2 turns; See

step 3).

e. Readjust Oven Air Shutter (See step 6).

pin 316417511 (En/Fr) 0609 3