INSTRUCTIONS FOR USE

Razor™ Plus 24D-26D-28D / Razor™ Plus 24C-28C — 909 5428 000(2)2005-01 3

– Carefully read alltheinstructionsbeforecarryingoutany

maintenance/repair operations.

– Before using the battery charger, ensure that frequency

and voltage values, indicated on the machine serial

number plate, match the mains voltage.

– Take all necessary precautions to prevent hair, jewelry

and loose clothes from being caught in the moving parts.

– Do not smoke while charging the batteries.

– Donotleave the machine unattended without beingsure

that the machine cannot move independently.

– Do not wash the machine with direct or pressurized

water jets, or with corrosive substances.

– Do not use the machine in particularly dusty areas.

– While using this machine, take care not to cause

damage to other people, especially children.

– Do not put any can containing fluids on the machine.

– The storage temperature must be between +32°F and

+104°F (0°C and +40°C).

– The machine operating temperature must be between

+32°F and +104°F (0°C and +40°C).

– The humidity must be between 30% and 95%.

– Always protect the machine against the sun, rain and

bad weather, both under operation and inactivity

condition.

– Do not use the machine as a means of transport.

– Do not use the machine on slopes with an inclination

higher than 2%.

– Do not allow the brushes to operate while the machine is

stationary to avoid damaging the floor.

– In case of fire, possibly use a powder fire extinguisher,

not a water one.

– Do not bump into shelves or scaffoldings, particularly

where there is a risk of falling objects.

– Donot tamperwith themachinesafetyguards andfollow

the ordinary maintenance instructions scrupulously.

– Do not remove or modify the plates affixed to the

machine.

– In case of machine malfunctions, ensure that these are

not due to lack of maintenance. Otherwise, request

assistance from the authorized personnel or from an

authorized Service Center.

– Ifparts mustbe replaced, require ORIGINALspareparts

from a Dealer or Authorized Retailer.

– To ensure the proper and safe operation of the machine,

have the scheduled maintenance, detailed in the related

chapter of this manual, performed by the authorized

personnel or an authorized Service Center.

– The machine must be disposed of properly, because of

the presence of toxic-harmful materials (batteries, etc.),

which are subject to standards that require disposal in

special centres (see the Scrapping chapter).

– If the machine is used according to the instructions, the

vibrations do not cause dangerous situations. The

machine vibration level is less than 2.5 m/s2.

– Do not leave any object penetrate in the openings. Do

not use the machine in case the openings are clogged;

always keep the openings free from dust, hairs and any

other foreign material which could reduce the air flow.

– This machine cannot be used on public roads.

– Pay attention during the machine transfers when

temperature is below freezing point. The water in the

recovery tank or in the hoses could freeze and seriously

damage the machine.

– Use only brushes and the pad-holders supplied with the

machine and those specified in the Instructions for Use

manuals. Using other brushes or pad-holders could

reduce safety.

UNPACKING

When the machine is delivered, check that the packing and

themachine were not damagedduringtransportation.Incase

of visible damages, keep the packing and have it checked by

the Carrier that delivered it. Call the Carrier immediately to fill

in a damage claim.

Pleasecheckthatthefollowingitemshavebeen suppliedwith

the machine:

1. Technical documents:

– Automatic Scrubber Instructions for Use Manual

– Electronic Battery Charger Manual

– Automatic Scrubber Spare Parts List

2. No. 2 lamellar fuses

3. No. 5 6V battery housing shims

MACHINE DESCRIPTION

AUTOMATIC SCRUBBER OPERATION

CAPABILITIES

The Automatic Scrubber is used to clean (scrubbing and

drying) smooth and solid floors, in civil or industrial

environment, under safe operation conditions by a qualified

Operator.

The Automatic Scrubber cannot be used for fitted carpet and

carpet washing.

CONVENTIONS

Forward, backward, front, rear, left or right are intended with

reference to the Operator position, that is to say with the

hands on the handlebar (2, Fig. C).

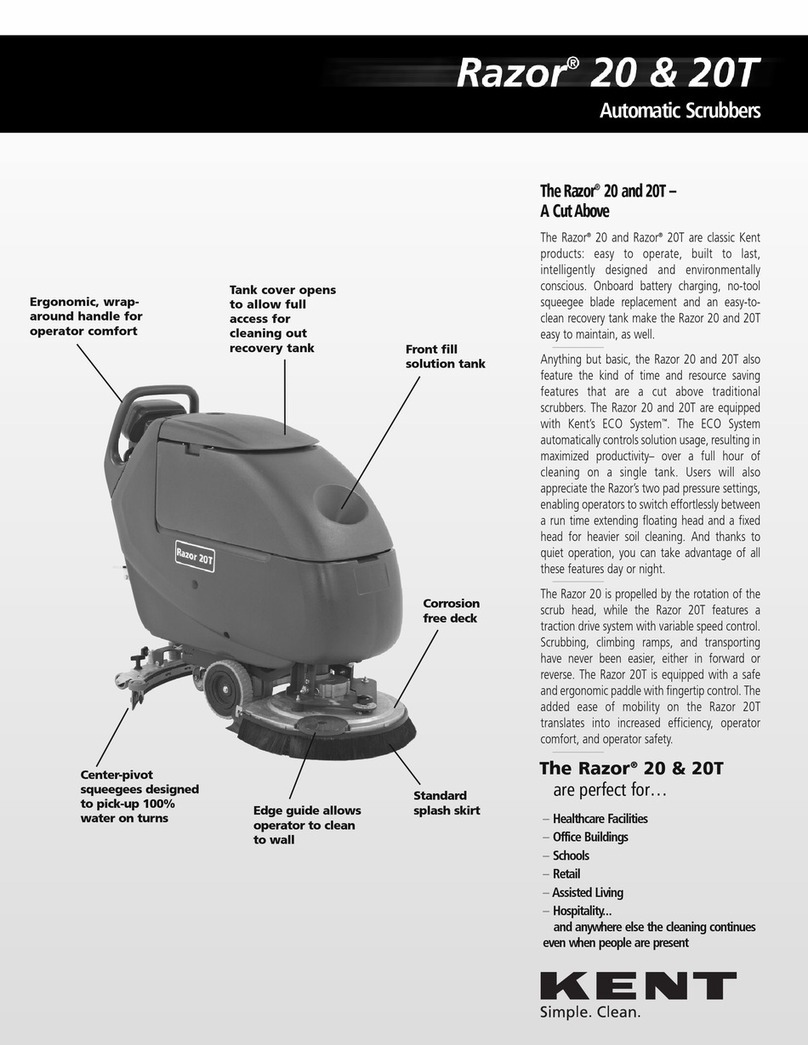

CONTROL PANEL DESCRIPTION

(See Fig. B)

1. Control panel

2. Brush/pad/cylindrical brush-holder deck lifting/lowering

switch

3. Brush or pad extra pressure switch (deactivated when

the cylindrical brush-holder deck is installed)

4. Solution flow control lever

5. Solution flow control lever “ECO” position (water

“economy” usage, for a washing autonomy of 70

minutes approximately)

6. Brush or pad-holder release switch

7. Forward/reverse speed adjuster

8. Hour counter

9. Battery charge indicator

9a. Green warning light (ON: charged batteries)

9b. Yellow warning light (ON: nearly discharged batteries)

9c. Red warning light (ON: discharged batteries)

10. Ignition key (0 - I)

WARNING!