3

SERVICE INFORMATION

To obtain consistent performance over the life of your

Kent equipment, read through these instructions and

save them for future reference. If you require service,

contact the dealer from which the machine was pur-

chased or an authorized service station. Always refer to

your limited warranty for complete service information.

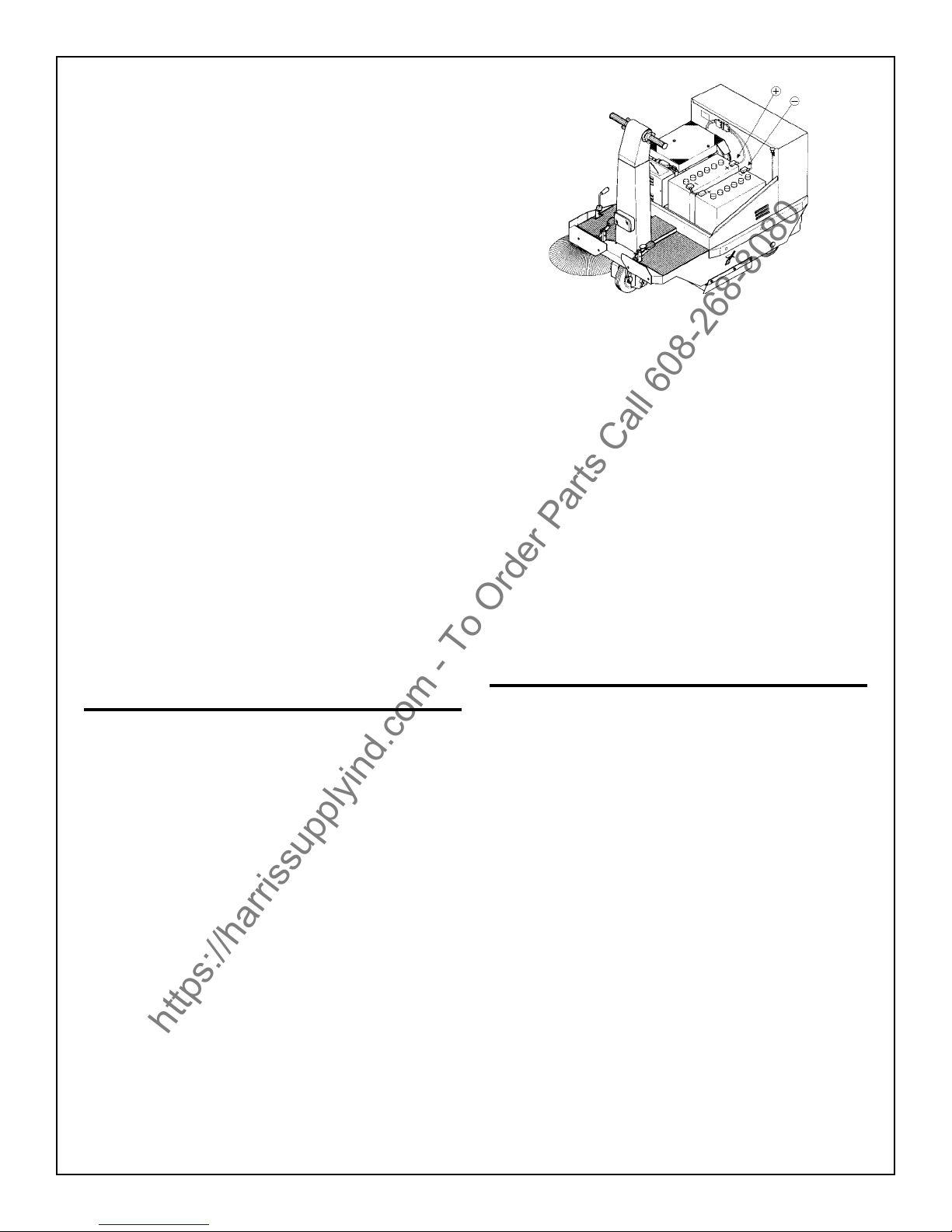

The model, type, and serial number are indicated on

the data plate located on the steel panel, inside the bat-

tery compartment. For prompt and accurate informa-

tion, refer to these numbers when inquiring about ser-

vice.

IMPORTANT SAFETY

INSTRUCTIONS

This manual is a guide for use of the machine and

information concerning the functioning, regulation, and

ordinary maintenance of your new sweeper. Your ma-

chine has been designed and constructed to ensure

maximum performance in a large variety of conditions.

Before delivery, the machine was checked in our fac-

tory to ensure that it will be delivered to you in perfect

condition. To maintain the machine in these conditions

and guarantee functioning without problems, it is very

important that routine maintenance, specified in the

Maintenance section of this manual, be properly per-

formed. Before using the machine, carefully read this

manual and keep it within easy reach for further refer-

ence. Indications of “left” and “right” are referred to in

the direction of movement of the sweeper. If you should

need any further information concerning the sweeper,

contact the dealer from which the machine was pur-

chased or an authorized service station.

This machine must not be used without its protective

equipment. For your own safety, make sure that all pro-

tective devices are closed or correctly in place before

each use of the machine. No safety program is effec-

tive without the total collaboration of the people directly

responsible for the functioning of the machine. The

majority of accidents which occur are a direct result of

the failure to follow the most elementary safety rules.

An alert and cautious operator is the best guarantee

against accidents and is worth more than any preven-

tion program.

SAVE THESE INSTRUCTIONS

READ THIS MANUAL BEFORE

ATTEMPTING TOASSEMBLE OR USE

THIS MACHINE!

SAFETY PRECAUTIONS

FOR THE SAFE OPERATION OF THIS MACHINE,

READ AND UNDERSTAND ALL WARNINGS.

ÿImproper use can cause personal injury.

ÿOperate only when lids, doors, and access panels

are securely closed.

ÿUse care when reversing machine in confined

areas.

ÿWhen servicing the machine, remove the key first

to prevent possible injury.

ÿWhen working with the machine on its side,

remove batteries, clear area of people and

obstructions, and use additional people and

proper procedures when lifting the machine.

ÿYou must have training in the operation of this

machine before using it. READ ALL OF THIS

MANUAL.

ÿDo not operate this machine unless it is com-

pletely assembled. Do not use this machine as a

step or furniture.

ÿBe careful when operating the machine on a

ramp or incline. Always move slowly on a ramp.

Do not turn this machine on a ramp. Do not stop

and leave this machine on a ramp.

ÿTo prevent injury, and damages to the machine,

do not lift the machine or move it to an edge of a

stair or loading dock.

ÿMachines can cause an explosion when operated

near flammable materials and vapors. Do not

use this machine with or near fuels, grain dust,

solvents, thinners, or other flammable materials.

ÿLead acid batteries generate gases that can

cause an explosion. Keep sparks and flames

away from batteries. NO SMOKING! Charge

batteries only in areas with good ventilation.

ÿAlways wear eye protection and protective

clothing when working near batteries. Remove

all jewelry. Do not put tools or other metal

objects across the battery terminals or on the top

surface of a battery.

ÿMaintenance and repairs must be done by

authorized personnel only. Tighten all fasteners.

Keep adjustments according to the specifications

given in this manual for the machine. Keep the

https://harrissupplyind.com-ToOrderPartsCall608-268-8080