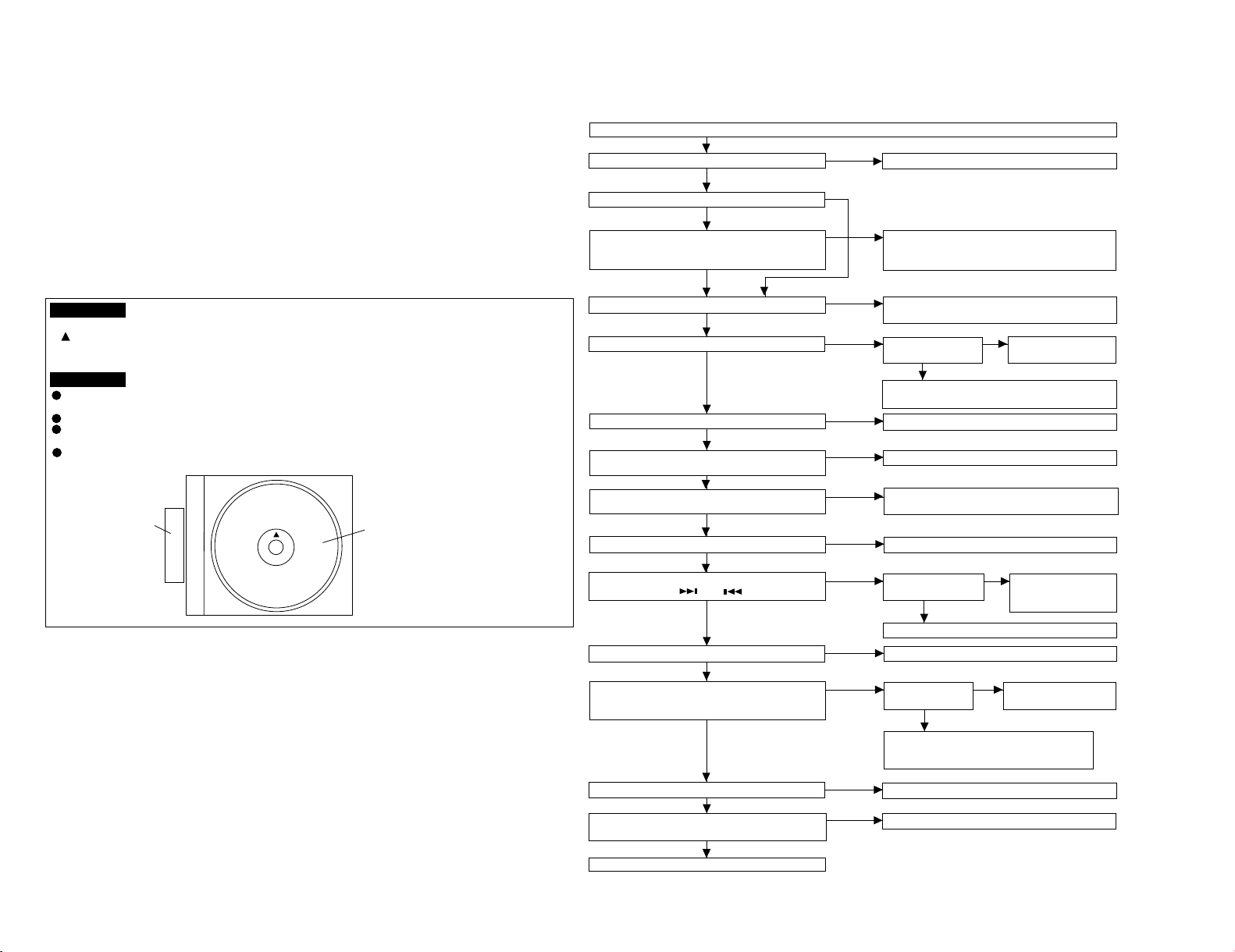

2. CD Test Mode (TEST 1)

In the CD test mode the operation of each step is possible even if the LID-SW is off. If focus cannot be taken in step 3 or any error

is processed, it is impossible to proceed to the next step. During error processing, end the test mode by pressing the ON/STAND-

BY button or return to the step 1 by pressing the CD STOP button. Any other operations are inhibited.

1. Step 1 Mode

When the CD test mode is obtained, the following display lights up. Then CD initialization operation flow proceeds up to CD

STB off to wait for the following buttons to be pressed.

One second after display lights up

Press the following buttons in this state to obtain the operations specified below.

"POWER" ................. Test mode and power turned off to shift to the ordinary standby mode.

"FF/FWD" ................. After the pickup returns to the innermost periphery, it slides toward the outer periphery while this button

is pressed.

"REW/REV" ..............After the pickup returns to the innermost periphery, it slides toward the inner periphery while this button

is pressed. If PICKUP IN is on, input is invalid.

"PLAY" ..................... Shift to step 2

"STOP" ..................... Invalid

"FUNCTION" ............ Shift to step 5

* In case of initialization, the pickup is moved toward the inner periphery. Any buttons other than "ON/STAND-BY" button are

not accepted until the shift of pickup to the inner periphery is completed at this time. If PICKUP IN SW ON cannot be detected

within 10 seconds, the slide motor stops, and the following error display appears. Press the ON/STAND-BY button to end

the test mode, or press the CD STOP button to return to step 1. Any other operations are inhibited.

The test mode applied to this microcomputer has three modes, namely the ordinary test mode for adjustment or measurement,

the aging test mode, and the self-diagnosis test mode for self-judgment in case of final product inspection.

1. Turning on the test mode

For obtaining each test mode, press the ON/STAND-BY button, while keeping pressing the following two buttons in the ordinary

stand-by mode (power off ). In this case, the main unit buttons are valid. When turning the ON/STAND-BY on with remote control

buttons, test modes are not obtained.

[Ordinary test mode]

1. CD Test Mode (TEST 1).....................................REW/PRESET DOWN + VOLUME UP

2. Tuner Test Mode (TEST 2).................................REW/PRESET DOWN + CD PLAY

3. Electronic Volume Test Mode (TEST 3)............. REW/PRESET DOWN + FF/PRESET UP

4. Timer Test Mode (TEST 4).................................FUNCTION + VOLUME UP

5. LCD Test Mode (TEST 5)...................................FUNCTION + FF/PRESET UP

6. Electric CD Lid Aging Test Mode (TEST 8)........ FUNCTION + CD PLAY

FUNCTION + VOLUME DOWN

[Self-diagnosis Test Mode]

1. Button input diagnosis test mode (TEST6).…....

Processes are different depending on destinations at initial settings.

The time display always indicates "0:00".

Press the following buttons in this state to obtain the operations specified below.

"POWER" ................ Test mode and power turned off to shift to the ordinary standby mode.

"FF/FWD" ................ The pickup slides toward the outer periphery while this button is pressed.

"REW/REV" ............. The pickup slides toward the inner periphery while this button is pressed. If PICKUP IN is on, input is

invalid.

"PLAY" ..................... Shift to step 5

"STOP" .................... Return to step 1

"FUNCTION" ........... Shift to step 5

*If the focus is not received, the process returns to step 1.

4. Step 4 Mode

The CLV servo ON command (8600) is transmitted to wait for the following buttons to be pressed. (The disc is rotated for CLV

lock.)

Press the following buttons in this state to obtain the operations specified below.

"POWER" ................ Test mode and power turned off to shift to the ordinary standby mode.

"FF/FWD" ................ The pickup slides toward the outer periphery while this button is pressed.

"REW/REV" ............. The pickup slides toward the inner periphery while this button is pressed. If PICKUP IN is on, input is

invalid.

"PLAY" ..................... If focus has been taken, shift to step 4 is executed. If not, acceptance is inhibited.

"STOP" .................... Return to step 1

"FUNCTION" ........... Shift to step 5

*If the focus is not received after it has been taken, the process returns to step 1.

3. Step 3 Mode

While the laser keeps lighting, CD initialization operation flow proceeds up to 'CLV servo ON' to wait for the following buttons

to be pressed.(Focus servo turned on for focus search)

The focus search is repeated to take focus.

Press the following buttons in this state to obtain the operations specified below.

"POWER" ................ Test mode and power turned off to shift to the ordinary standby mode.

"FF/FWD" ................ The pickup slides toward the outer periphery while this button is pressed.

"REW/REV" ............. The pickup slides toward the inner periphery while this button is pressed. If PICKUP IN is on, input is

invalid.

"PLAY" ..................... Shift to step 3

"STOP" .................... Return to step 1

"FUNCTION" ........... Shift to step 5

2. Step 2 Mode

Press the "CD PLAY" button in this mode to transmit the laser lighting command LDON (8400) and turn on the laser. Any other

operations are not performed in this case.