RD-M52MD/M72MD

7

CIRCUIT DESCRIPTION

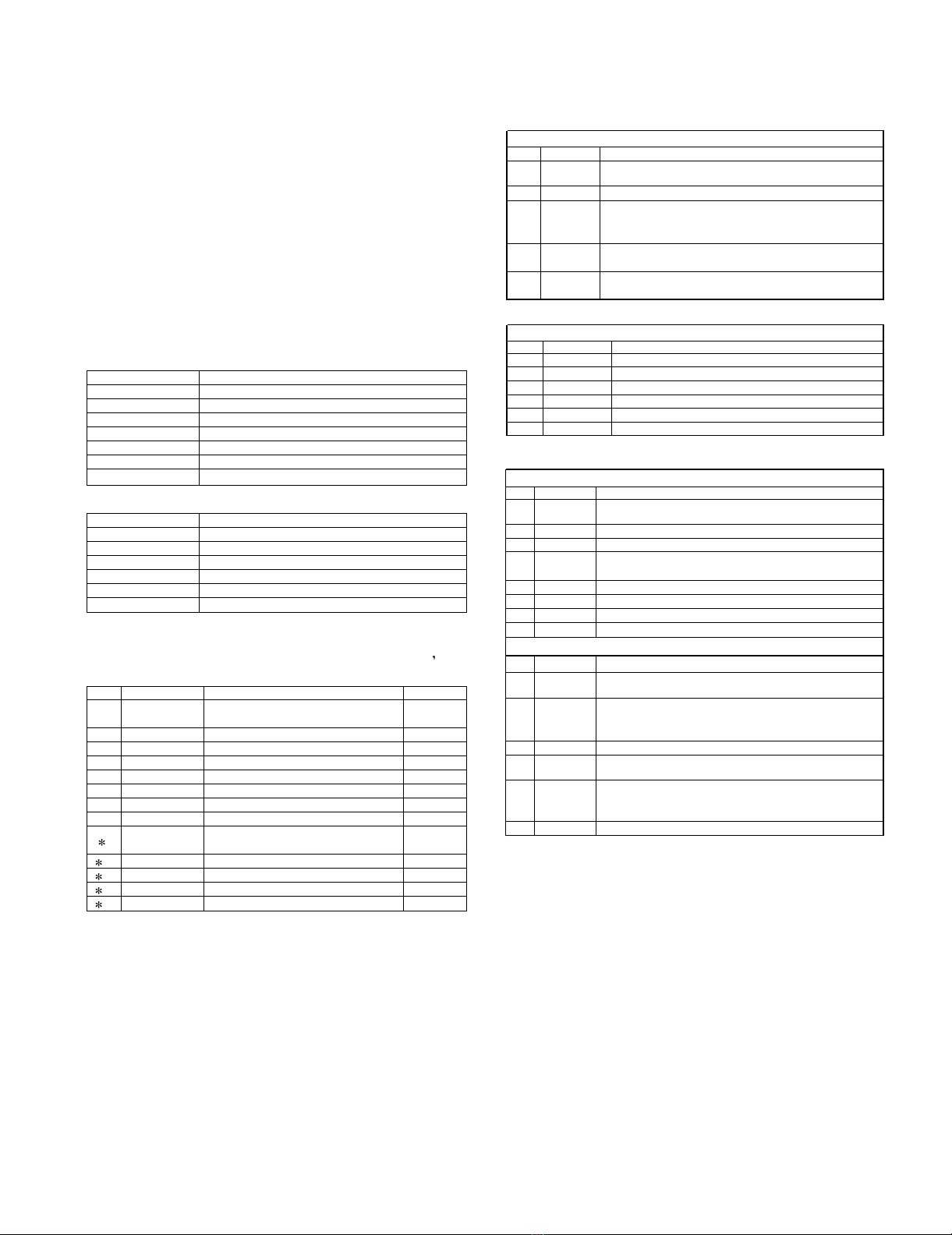

1. Setting of Continuous Playback Mode

No. Key

1

Volume/

multi-control

Select [CPLAY MODE]

2 Load disc

3 PLAY [CPLAY MID]

[c=xxxx a=yy] error

(xxxx=C1 error, yy=ADIP error)

4 MODE [CPLAY(zzzz)] CPLAY address

(MID=0300h, OUT=0700h, IN=0030h cluster)

5 MODE [h✽✽✽✽d@@@@] address

(✽✽✽✽=current head address, @@@@=ADIP address)

In No.5, Display shows [-] if can't read disc.

2. Change of Playback Points(in continuous playback mode)

No. Key

Display/Function

Display/Function

1 PLAY [CPLAY OUT]

2 Carry out No.4 and 5 in the above table.

3 PLAY [CPLAY IN]

4 Carry out No.4 and 5 in the above table.

5 STOP [CPLAY MODE]

6 EJECT Disc out

1. Continuous Recording Setting

No. Key Display/Function

1

Volume/

multi-control

Select [CREC MODE]

2 Load the recordable disc

3 PLAY [CREC MID]

4 PLAY [CREC (zzzz)] CREC address

(0300h cluster=recording start point)

5 DISPLAY [h✽✽✽✽d@@@@] address

6 DISPLAY [c=xxxx a=yy] error

7 DISPLAY [CREC (zzzz)]

8 STOP [CREC MODE]

2. Change and End of Recording Points

1 Carry out No.1 to 3 in the above table Select[CREC MID]

2

Volume/

multi-control

[CREC OUT]

3 PLAY [CREC (zzzz)] CREC address

(0700h cluster=recording start point)

Carry out No.5 to 8 in the above table

4 PLAY Select [CREC MID]

5

Volume/

multi-control

Select [CREC IN]

6 PLAY [CREC (zzzz)] CREC address

(0300h cluster=recording start point)

Carry out No.5 to 8 in the above table

7 EJECT Disc out

Starting address is the followings.

IN=30h cluster, MID=300h cluster, OUT=700h cluster

For more information on each adjustment mode, refer to

each section of 7, "Electrical adjustment".

If other adjustment mode has been entered incorrectly,

press the STOP key to exit the mode.

* The number 9 - 13 are not used for service. If these

mode have been entered incorrectly, press the STOP

key immediately to exit the mode. Specially, do not use

EEP INITIAL. (E2PROM data has initialized if used it.)

1. The recording start addresses of IN, MID, and OUT are

described below.

IN 30H cluster

MID 300H cluster

OUT 700H cluster

2. An erasure prevention control is not detected in the test

mode. Be careful not to enter the continuous recording

mode using a disc containing the data that should not be

erased.

3. Do not record continuously for more than five minutes.

4. Take care that no vibration is applied during continuous

recording.

6-6 Continuous Playback Mode

6-7 Continuous Recording Mode

5 Initializing the MD Mechanism

5-1 Initialization Method

While pressing the MD [PLAY/PAUSE] key and MD

[EJECT] key simultaneously,

turn the AC on.

6. MD Test Mode for Adjustment

6-1 Entering the Test Mode

While pressing the MD [PLAY/PAUSE] key and [rec] key

simultaneously,

turn the AC on.

6-2 Cancelling the Test Mode

Turn the AC off.

6-3 Key Operations for Adjustment

No. LCD DESCRIPTION SECTION

1 TEMP ADJU The work of adjustment is unnecessary

in this mode. 7-5

2 LDPWR ADJU Laser power adjustment. 7-6

3 LDPWR CHEC Laser power check. 7-6

4 EFBAL ADJU Traverse adjustment. 7-7

5 TE B. ADJ Automatic EF balance adjustment. -

6 FBIAS ADJU Focus bias adjustment. 7-8

7 CPLAY MODE Continuous playback mode. 6-6

8 CREC MODE Continuous recording mode. 6-7

9 STT-LIMIT Check the mechanism start limit

switch position. -

10 JUMP MODE Track jump checking mode. -

11 SRV DAT RE Servo data reading. -

12 EEP MODE E2PPROM data reading or rewrite. -

13 EEP INITIAL E2PPROM data initializing. -

KEYS OPERATION

Volume/multi- control Select mode or adjustment value change.

MD PLAY/PAUSE Fix mode or adjustment value.

STOP Cancel the selected mode and change to menu page.

menu/demo Select servo of PIT or GROOVE.

display Change-over the display mode.

SKIP UP Pickup moves outwards when pressed skip up key.

SKIP DOWN Pickup moves inwards when pressed skip down key.

LDC DESCRIPTION

> Servo on.

>> Tracking servo on.

GRV Servo groove mode.

CLV-S Rough servo clock.

CLV-A Spindle lock.

RECORD Recordable disc or no disc.

6-4 LCD Indication for Mechanism Operation

6-5 Selection of Adjustment Test Mode

Whenever the [volume/multi-control] knob is turned the

adjustment test mode is selected.

www.freeservicemanuals.info

Digitized in Heiloo the Netherlands