2/ 3

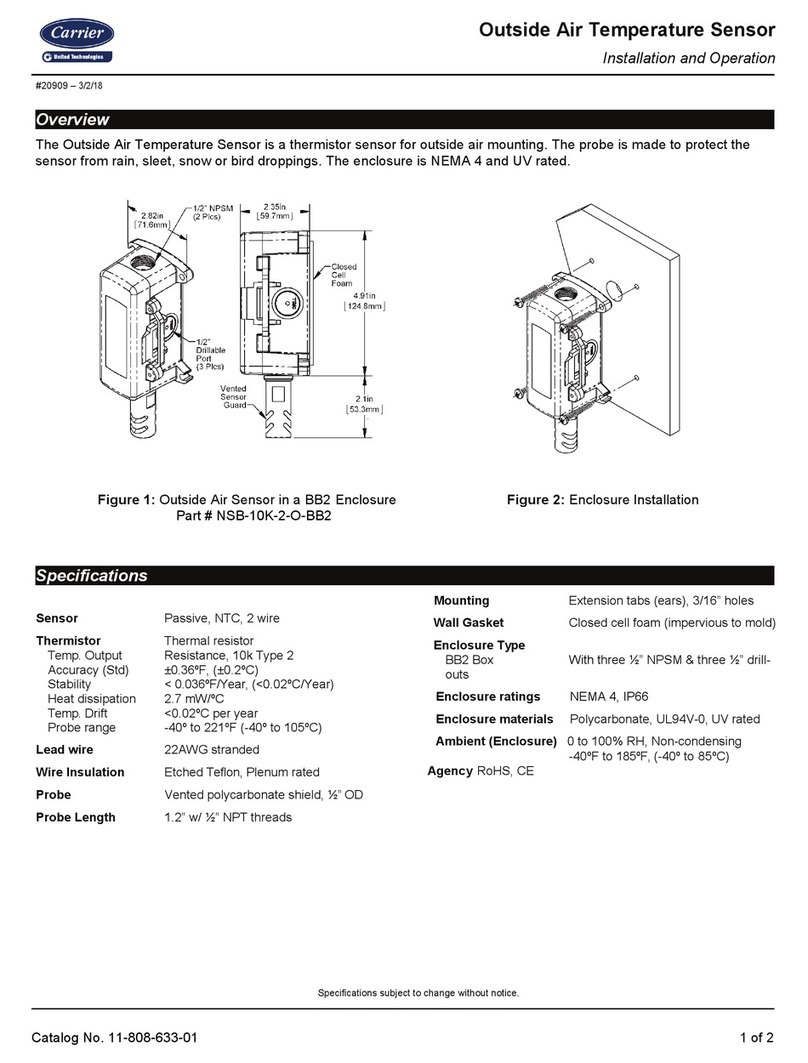

A. This is 10K NTC sensor, need not to distinguish positive or negative when wiring

sensor.

B. The input voltage must within the voltage value marked in diagram ±10% value.

C. Load Power ≤ Votage of load ∗ Max current of Relay

Factor

The factor for Inductive Load like compressor, heating pump, usually be 5~8;

The factor for Resistive Load like Electric heating rod, Electric blanket

usually is 1.5~2;

The factor for Incandescent lamp usually is 15.

6. Configurations

6.1. Function & Parameter

Temperature Calibration (°F )

6.2. How to set my ideal temperature?

We call it ATV means Aim Temperature Value (default 5°F) which is the ideal

temperature value you wish to keep around, once exceed this value (if difference value =

0) the working status of load will be changed; and ATV must between the lower limit and

higher limit.

Assure power on, Press and release key once time you will find display

blink a data which is changeable

Now press or keys to get you aim value.

Waiting 10s the device will save data automatically or press to save it

6.3. When will the load working?

Firstly of all, the instant time passed the delay time, and then matches one of the following

In heating mode, the relay will turn on heater when

Measured Temperature Value ≤ ATV - Temp. Differential

In Cooling mode, the relay will turn on cooler

Measured Temperature Value ≥ ATV + Temp. Differential

6.4. How to set other parameters?

Press and hold on 3s until appears the code HC.

Now press the or keys to select the code you want to update;

Press and release to see exist value; now Press the or keys in order

to get you aim value;

Press key to memorize the configured value and return to the menu.

Repeat operation from step 2 / 3 / 4 to adjust other parameters;

Press to save data and quit from setting mode back to normal monitor status.

Actually modified value will be memorized automatically if without operation

in 10s

6.5. How to get Factory Reset?

In normal status, press and keys in same time, do not release them until screen

shows YS which means success, nearly 3s.

7. Error & Alarm

When alarm occur, if the readout flash --- and buzzer sounds,

Press any key to stop buzz scream;

Check the room temperature and then change the compressor / heater working status

manually if need,

fix or replace the sensor; after that screen will back to normal state

And other code please, reference below content to fix problem.

Measured temperature > HS

Check the refrigerator or heater

Measured temperature < LS

Check the refrigerator or heater

8. Environmental Information

The packages material is 100% recyclable; Just dispose it through

specialized recyclers.

The electro components can be recycled or reused if it is disassembled

for specialized companies.

Please do not burn or throw the controllers in domestic garbage,

observe the respectively law in your region concerning the

environmental responsible manner of dispose its devices.